1

DEFINITIONS

1.1 INTRODUCTION

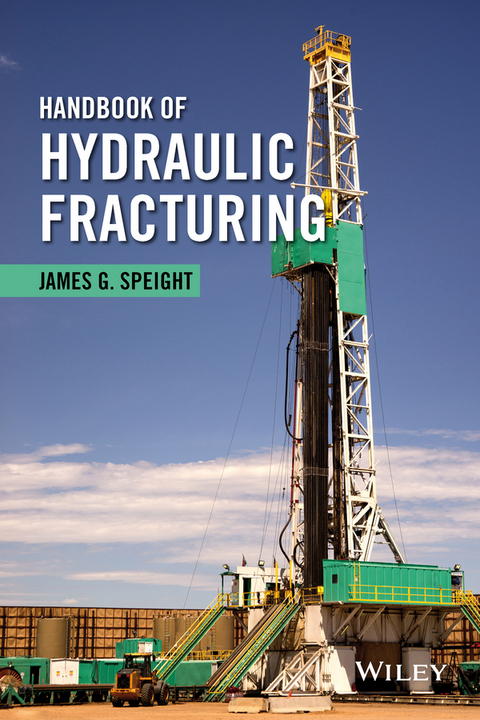

Hydraulic fracturing (also known as hydrofracturing, hydrofracking, fracking, fraccing, or fracture stimulation technology, or various other derivatives of the term) is a method by which access to crude oil and natural gas trapped in impermeable and hard-to-reach geologic formations is achieved.

The hydraulic fracturing process involves the pressurized injection of a fluid (fracturing fluid) into geologic formations (shale formations or unusually tight rock formations consisting of a clastic sedimentary rock composed of silt- to clay-sized grains) until the reservoir rock cracks (causing fractures in the formations) and then extending that fracture by continued injection of fluid. A solid proppant, typically sand, is also injected into the formation with the fracturing fluid so that the fracture cannot close and remains propped open by the proppant left behind. This creates a flow path for reservoir fluids to be rapidly produced from the reservoir. In terms of project timing, the process may take less than 1 month with reward being decadelong production of crude oil and natural gas. Thus, a general timeline might by on the order of:

| Timeline (approximate, site specific): |

| Drilling (2–4 weeks) | Fracturing (3–5 days) | Producing oil/gas (decades) |

Once the formation is fractured, the fluid pressure is reduced, which reverses the direction of fluid flow in the well toward the ground surface. Both the hydraulic fracturing fluid and any naturally occurring substances released from the underground formation are allowed to flow back to the ground surface. Thus, the term flowback is the portion of the injected fracturing fluid that flows back to the surface, along with oil, gas, and brine, when the well is produced.

In addition, hydraulic fracturing for enhancing crude oil and natural gas production can be categorized into three general subcategories according to process applied to the target formation to induce fracturing:

- Hydraulic fracturing involves a relatively low rate of pressure loading that results in a bidirectional fracture extending outward from the well and oriented perpendicular to the least principal rock stress. Because of the creation of a single fracture and the ability to pump large volumes of fluids at (relatively) low rates, the potential penetration for the fracture into the formation can be extensive—on the order of hundreds of feet. This method is currently the most widely used in the coal-mine methane/coalbed methane (CMM/CBM) industry.

- On the other hand, explosive fracturing involves rapid pressurization of the target formation, which results in a highly fractured zone around the wellbore, but usually not exceeding of approximately 10 ft. Because the peak pressures exceed both the minimum and maximum horizontal in situ stresses, a radial fracture pattern is created, which can exhibit advantageous fracture geometry where near-wellbore stimulation is the primary objective.

- The third case involves pulse fracturing (Walter and Thompson, 1982), which is characterized by pressures exceeding both the maximum and minimum in situ stresses and which also creates a radial fracture pattern. This technique results in multiple vertical fractures extending radially from the wellbore, with penetrations on the order of 10–20 ft.

When used in combination with horizontal drilling (Chapter 5), hydraulic fracturing has allowed access to crude oil and natural gas reserves previously considered uneconomical because of the difficulty of access. The energy crises of the 1970s highlighted the importance of energy security, and governments took a more active role in encouraging domestic sources of supply, including unconventional sources of crude oil and natural gas (Speight, 2011). In addition, these reserves of crude oil and natural gas have the potential to assert a measure of energy independence that is necessary for countries that are experiencing a depletion of conventional crude oil and natural gas reserves and must rely upon imports of crude oil and natural gas from countries that, in many cases, do not have stable governments or stable energy policies (Speight, 2011, 2014a; Trembath et al., 2013).

On the US domestic scenario, hydraulic fracturing has been employed in the United States since 1947 but has only recently been used to produce large quantities of crude oil and natural gas from shale formations, as new technology for drilling horizontal wells has been deployed (Chapter 5) and, in spite of a variety of negative (often emotional rather than scientific) comments in various media, is projected to continue to play a central role in future domestic energy policy. Nevertheless, caution is advised because although hydraulic fracturing creates access to more crude oil and natural gas supplies, the process requires the use of large quantities of water and fracturing fluids, which are injected underground at high volumes and pressure. The composition of the fracturing fluids varies by formation (therefore is site specific) and can range from a simple benign mixture of water and sand to more complex mixtures with a variety of chemical additives.

Despite the length of time that hydraulic fracturing has been used and despite the fact that the process has helped to create a benefit to energy production and economic growth (Chapter 5), there has been much negative attention that has given rise to serious concerns about the application of the technology. This is especially true in relation to the possibility (some would say reality) of contaminated drinking water because of the chemicals used in the process and the disturbance of the geological formations.

Because of the need for a thorough understanding of petroleum and natural gas and the associated technologies for recovery of these energy resources, it is essential that the definitions and the terminology of petroleum science and technology and associated resources (Table 1.1) be given prime consideration. This will aid in a better understanding of the variation in types of petroleum (with the exception of tar sand bitumen, which is not classed as petroleum), its constituents, the various fractions, and petroleum products. Of the many forms of terminology that have been used, not all have survived, but the more commonly used are illustrated here. Particularly troublesome, and more confusing, are those terms that are applied to the more viscous materials, for example, the use of the terms tar sand bitumen and asphalt (Speight, 2014a, 2015a, 2015c).

Table 1.1 Simplified Differentiation between Conventional Crude Oil, Heavy Oil, Extra Heavy Oil, Tar Sand Bitumen, Oil Shale Kerogen, Tight Oil, and Coal

| High-permeability reservoir |

| High-permeability reservoir |

| Tertiary recovery (enhanced oil recovery (EOR), e.g., steam stimulation) |

| High-permeability reservoir |

| Tertiary recovery (enhanced oil recovery (EOR), e.g., steam stimulation) |

| High-permeability reservoir |

| Mining (often preceded by explosive fracturing) |

| Steam-assisted gravity drainage (SAGD) |

| Low-permeability reservoir |

| May involve explosive fracturing |

| In situ thermal decomposition to produce shale oil |

| Mining followed by thermal decomposition to produce shale oil |

| Immobile in the reservoir |

| Low-permeability reservoir |

| Horizontal drilling into reservoir |

| Fracturing (typically multifracturing) to release fluids/gases |

| Low- to medium-permeability reservoir (coal seam) |

| Gas exists in pore spaces |

| In situ thermal decomposition to produce liquid products |

| Mining (often preceded by explosive fracturing), followed by thermal decomposition to produce liquid products |

It is the purpose of this chapter to alleviate much of the confusion that exists, but it must be remembered that the...