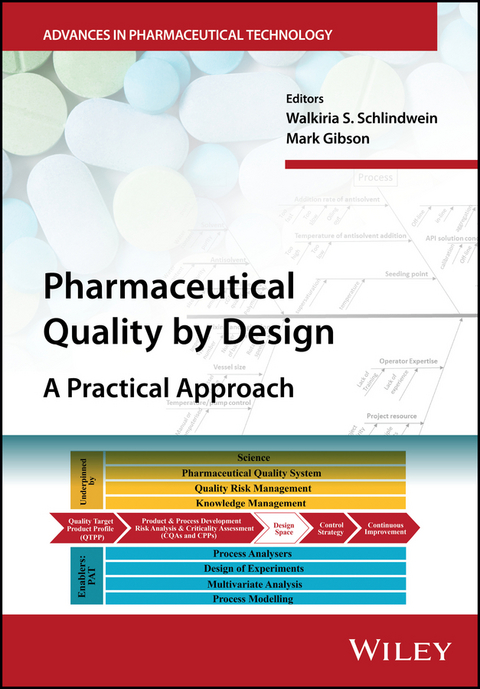

Pharmaceutical Quality by Design (eBook)

John Wiley & Sons (Verlag)

978-1-118-89521-4 (ISBN)

A practical guide to Quality by Design for pharmaceutical product development

Pharmaceutical Quality by Design: A Practical Approach outlines a new and proven approach to pharmaceutical product development which is now being rolled out across the pharmaceutical industry internationally. Written by experts in the field, the text explores the QbD approach to product development. This innovative approach is based on the application of product and process understanding underpinned by a systematic methodology which can enable pharmaceutical companies to ensure that quality is built into the product.

Familiarity with Quality by Design is essential for scientists working in the pharmaceutical industry. The authors take a practical approach and put the focus on the industrial aspects of the new QbD approach to pharmaceutical product development and manufacturing. The text covers quality risk management tools and analysis, applications of QbD to analytical methods, regulatory aspects, quality systems and knowledge management. In addition, the book explores the development and manufacture of drug substance and product, design of experiments, the role of excipients, multivariate analysis, and include several examples of applications of QbD in actual practice. This important resource:

- Covers the essential information about Quality by Design (QbD) that is at the heart of modern pharmaceutical development

- Puts the focus on the industrial aspects of the new QbD approach

- Includes several illustrative examples of applications of QbD in practice

- Offers advanced specialist topics that can be systematically applied to industry

Pharmaceutical Quality by Design offers a guide to the principles and application of Quality by Design (QbD), the holistic approach to manufacturing that offers a complete understanding of the manufacturing processes involved, in order to yield consistent and high quality products.

Editors

Walkiria S. Schlindwein is Associate Professor of Pharmaceutics at the School of Pharmacy, De Montfort University. Walkiria is the programme leader of two Postgraduate courses in Pharmaceutical Quality by Design.

Mark Gibson is Director of AM PharmaServices Ltd. He is a practicing Pharmaceutical Consultant and was formerly with AstraZeneca.

A practical guide to Quality by Design for pharmaceutical product development Pharmaceutical Quality by Design: A Practical Approach outlines a new and proven approach to pharmaceutical product development which is now being rolled out across the pharmaceutical industry internationally. Written by experts in the field, the text explores the QbD approach to product development. This innovative approach is based on the application of product and process understanding underpinned by a systematic methodology which can enable pharmaceutical companies to ensure that quality is built into the product. Familiarity with Quality by Design is essential for scientists working in the pharmaceutical industry. The authors take a practical approach and put the focus on the industrial aspects of the new QbD approach to pharmaceutical product development and manufacturing. The text covers quality risk management tools and analysis, applications of QbD to analytical methods, regulatory aspects, quality systems and knowledge management. In addition, the book explores the development and manufacture of drug substance and product, design of experiments, the role of excipients, multivariate analysis, and include several examples of applications of QbD in actual practice. This important resource: Covers the essential information about Quality by Design (QbD) that is at the heart of modern pharmaceutical development Puts the focus on the industrial aspects of the new QbD approach Includes several illustrative examples of applications of QbD in practice Offers advanced specialist topics that can be systematically applied to industry Pharmaceutical Quality by Design offers a guide to the principles and application of Quality by Design (QbD), the holistic approach to manufacturing that offers a complete understanding of the manufacturing processes involved, in order to yield consistent and high quality products.

Editors Walkiria S. Schlindwein is Associate Professor of Pharmaceutics at the School of Pharmacy, De Montfort University. Walkiria is the programme leader of two Postgraduate courses in Pharmaceutical Quality by Design. Mark Gibson is Director of AM PharmaServices Ltd. He is a practicing Pharmaceutical Consultant and was formerly with AstraZeneca.

List of Figures

| Figure 1.1 | A framework for QbD. |

| Figure 2.1 | Medicinal product development flowchart. |

| Figure 2.2 | Overview of a typical quality risk management process (ICH Q9). |

| Figure 2.3 | Example of risk assessment tool: flowchart (basic tool). |

| Figure 2.4 | Example of a cause and effect diagram (Ishikawa fishbone diagram). |

| Figure 2.5 | Overall QRA process flow for the medicinal product. |

| Figure 2.6 | Risk score approach (high level) based on current operating space. |

| Figure 2.7 | Risk score approach (detailed level) based on current operating space. |

| Figure 2.8 | Tacit benefits of QRM. |

| Figure 3.1 | Through the ages. |

| Figure 3.2 | ICH QbD timeline. |

| Figure 3.3 | From data to knowledge. |

| Figure 4.1 | Example of a convergent synthesis. |

| Figure 4.2 | Temperature–solubility curve for AZD3342 in 1‐propanol:water and IMS:water. |

| Figure 4.3 | Solubility–temperature and metastable zone limit curves. |

| Figure 4.4 | Effect of cooling rate on the metastable zone width of sibenadet HCl. |

| Figure 4.5 | Crystal16 data for AZD3342 polymorphs A and G. |

| Figure 4.6 | Cooling crystallization scenarios: (a) natural cooling, (b) linear cooling, (c) controlled cooling. |

| Figure 4.7 | Effect of seed loading on particle size. |

| Figure 4.8 | UV Data for an unseeded linear cooling crystallization of AZD3342. |

| Figure 4.9 | FBRM Lasentec data and Photomicrograph for an unseeded, linear cool crystallization of AZD3342. |

| Figure 4.10 | UV Data for the dissolution and crystallization of AZD3342 using seeding and a cubic cooling profile (controlled cooling). |

| Figure 4.11 | FBRM Lasentec data and optical microscopy of AZD3342 crystals using seeding and a cubic cooling profile (controlled cooling). |

| Figure 4.12 | Typical Ishikawa diagram for an anti‐solvent crystallization process. |

| Figure 5.1 | Examples of “known and unknowns” to users and suppliers. |

| Figure 6.1 | Process of determining how a quality attribute is deemed critical. *A severity scale is used to assess relative magnitude. |

| Figure 6.2 | Examples of where CQAs may be impacted in the manufacturing process for an oral solid dosage form. |

| Figure 6.3 | PDA decision tree for designating parameter criticality. |

| Figure 6.4 | Fishbone diagram recognising material attributes (MAs) and process parameters (PPs) contributing to the quality attribute, ‘solubility’, of a solid dispersion API/polymer product. |

| Figure 6.5 | Use of risk assessment to determine what DoE studies to use. |

| Figure 6.6 | Example of a process parameter criticality assessment decision tree. |

| Figure 6.7 | The manufacturing process flow for ACE tablets. |

| Figure 6.8 | Critical parameters affecting blend uniformity for ACE tablets. |

| Figure 6.9 | Schematic representation of the relationship between knowledge, design, and control space. |

| Figure 6.10 | Example of terminal sterilisation design space. |

| Figure 6.11 | Comparison of traditional controls with advanced controls for the real‐time release of an oral solid dosage form. |

| Figure 7.1 | Constructing a variability gauge chart. |

| Figure 7.2 | Impact of formulation of disintegration time with outlier. |

| Figure 7.3 | Impact of formulation on disintegration with the corrected data point. |

| Figure 7.4 | Prediction profilers showing the impact of formulation on disintegration time. |

| Figure 7.5 | Statistical analysis of the disintegration time data. |

| Figure 7.6 | Comparison of the statistical analysis of Study A and Study B. |

| Figure 7.7 | Identifying sources of variation. |

| Figure 7.8 | The GlaxoSmithKline reaction simulator. |

| Figure 7.9 | ‘Understanding and Optimizing Chemical Processes’ 2015 Workshop results. |

| Figure 7.10 | Costs, risks and benefits of classical designs. |

| Figure 7.11 | Data visualization. |

| Figure 7.12 | Analysis of the half fraction. |

| Figure 7.13 | Prediction profiles for the four different designs (shaded boxes indicate statistically significant effects). |

| Figure 7.14 | Interaction effects. |

| Figure 7.15 | Explaining the experimental procedure to the ‘novice’ workshop delegate. |

| Figure 7.16 | Comparison of ‘expert’ and ‘novice’ findings for the half fraction design. |

| Figure 7.17 | Theoretical model of a specific real‐world situation. |

| Figure 7.18 | Cycles of learning iterate between the real world and our model of it. |

| Figure 7.19 | Resource requirements for central composite design. |

| Figure 7.20 | Simulation scenario schematic. |

| Figure 7.21 | Analysis of the 10 run fractional factorial experiment. |

| Figure 7.22 | Prediction profiler for the 10 run fractional factorial. |

| Figure 7.23 | Analysis of the central composite design. |

| Figure 7.24 | Analysis of the 13 run DSD experiment. |

| Figure 7.25 | Comparison of the central composite and definitive screening design (DSD). |

| Figure 8.1 | Notation used in principal components analysis (PCA). |

| Figure 8.2 | PCA derives a model that fits the data as well as possible in the least squares sense. Alternatively, PCA may be understood as maximizing the variance of the projection coordinates. |

| Figure 8.3 | The raw data curves of the 45 batches of the training set. |

| Figure 8.4 | Scatter plot of the two principal components. Each point represents one batch of raw material. The plot is color‐coded according to supplier. |

| Figure 8.5 | Loading line plots of the two principal components. |

| Figure 8.6 | Scores and DModX plots for the particle size distribution data set. Top left: Predicted scores for the test set batches. Top right: Scores for the training set batches. Bottom left: Predicted DModX for the test set batches. Bottom right: DModX for the training set batches. |

| Figure 8.7 | Line plot of the power spectral density (PSD) curves of the six early (red color) and three late (black color) batches of supplier L3. |

| Figure 8.8 | Spanning batches can be selected using DoE. Such spanning batches can be subjected to a thorough investigation in order to ensure production robustness in all part of the PCA score space. |

| Figure 8.9 | (Left) Scatter plot of HS_1 against HS_2, (right) PLS t1/t2 score plot (note the resemblance to Figure 8.8). |

| Figure 8.10 | (Left) Summary of fit plot of the PLS model of the SOVRING subset with complete Y‐data. Five components were significant according to cross‐validation. (Right) Individual R2Y‐ and Q2Y‐values of the six responses. The most important responses are PAR, FAR, %Fe_FAR and %P_FAR. |

| Figure... |

| Erscheint lt. Verlag | 5.1.2018 |

|---|---|

| Reihe/Serie | Advances in Pharmaceutical Technology |

| Advances in Pharmaceutical Technology | Advances in Pharmaceutical Technology |

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie ► Technische Chemie |

| Technik | |

| Schlagworte | chemical engineering • Chemical Engineering Fundamentals • Chemie • Chemische Verfahrenstechnik • Chemistry • examples of QbD • Grundlagen der Chemischen Verfahrenstechnik • Guide to QbD for pharmaceutical industry • Guide to Quality by Design for pharmaceutical industry • holistic approach to pharmaceutical manufacturing • Mark Gibson • Medizinische Chemie • Pharmaceutical & Medicinal Chemistry • Pharmaceutical Quality by Design A Practical Approach • Pharmazeutische Chemie • Pharmazeutische u. Medizinische Chemie • principles of QbD • principles of quality by design • QbD and FDA • QbD and manufacturing active pharmaceutical ingredients • QbD and risk management tools. Quality by Design and risk management analysis • Qualitätssicherung • Qualitätssicherung in der Chemie • Quality assurance • quality by design and design of experiments • quality by design and knowledge management • quality by design and manufacture of drug substance • quality by design and multivariate analysis • quality by design and the role of excipients • Walkiria S. Schlindwein |

| ISBN-10 | 1-118-89521-5 / 1118895215 |

| ISBN-13 | 978-1-118-89521-4 / 9781118895214 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich