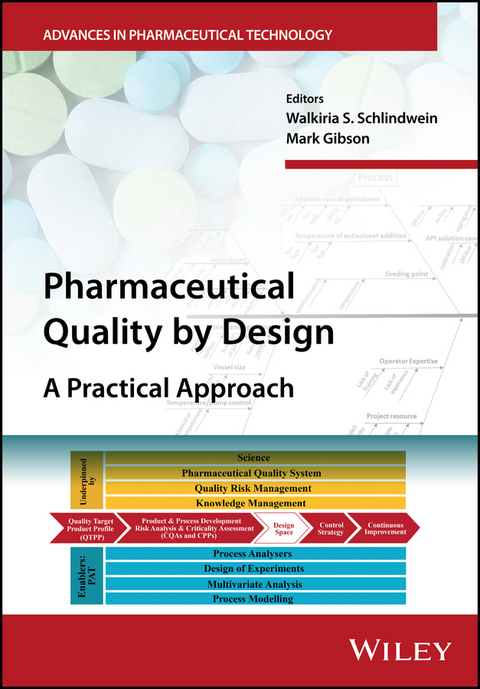

Pharmaceutical Quality by Design (eBook)

John Wiley & Sons (Verlag)

978-1-118-89522-1 (ISBN)

A practical guide to Quality by Design for pharmaceutical product development

Pharmaceutical Quality by Design: A Practical Approach outlines a new and proven approach to pharmaceutical product development which is now being rolled out across the pharmaceutical industry internationally. Written by experts in the field, the text explores the QbD approach to product development. This innovative approach is based on the application of product and process understanding underpinned by a systematic methodology which can enable pharmaceutical companies to ensure that quality is built into the product.

Familiarity with Quality by Design is essential for scientists working in the pharmaceutical industry. The authors take a practical approach and put the focus on the industrial aspects of the new QbD approach to pharmaceutical product development and manufacturing. The text covers quality risk management tools and analysis, applications of QbD to analytical methods, regulatory aspects, quality systems and knowledge management. In addition, the book explores the development and manufacture of drug substance and product, design of experiments, the role of excipients, multivariate analysis, and include several examples of applications of QbD in actual practice. This important resource:

- Covers the essential information about Quality by Design (QbD) that is at the heart of modern pharmaceutical development

- Puts the focus on the industrial aspects of the new QbD approach

- Includes several illustrative examples of applications of QbD in practice

- Offers advanced specialist topics that can be systematically applied to industry

Pharmaceutical Quality by Design offers a guide to the principles and application of Quality by Design (QbD), the holistic approach to manufacturing that offers a complete understanding of the manufacturing processes involved, in order to yield consistent and high quality products.

Editors

Walkiria S. Schlindwein is Associate Professor of Pharmaceutics at the School of Pharmacy, De Montfort University. Walkiria is the programme leader of two Postgraduate courses in Pharmaceutical Quality by Design.

Mark Gibson is Director of AM PharmaServices Ltd. He is a practicing Pharmaceutical Consultant and was formerly with AstraZeneca.

A practical guide to Quality by Design for pharmaceutical product development Pharmaceutical Quality by Design: A Practical Approach outlines a new and proven approach to pharmaceutical product development which is now being rolled out across the pharmaceutical industry internationally. Written by experts in the field, the text explores the QbD approach to product development. This innovative approach is based on the application of product and process understanding underpinned by a systematic methodology which can enable pharmaceutical companies to ensure that quality is built into the product. Familiarity with Quality by Design is essential for scientists working in the pharmaceutical industry. The authors take a practical approach and put the focus on the industrial aspects of the new QbD approach to pharmaceutical product development and manufacturing. The text covers quality risk management tools and analysis, applications of QbD to analytical methods, regulatory aspects, quality systems and knowledge management. In addition, the book explores the development and manufacture of drug substance and product, design of experiments, the role of excipients, multivariate analysis, and include several examples of applications of QbD in actual practice. This important resource: Covers the essential information about Quality by Design (QbD) that is at the heart of modern pharmaceutical development Puts the focus on the industrial aspects of the new QbD approach Includes several illustrative examples of applications of QbD in practice Offers advanced specialist topics that can be systematically applied to industry Pharmaceutical Quality by Design offers a guide to the principles and application of Quality by Design (QbD), the holistic approach to manufacturing that offers a complete understanding of the manufacturing processes involved, in order to yield consistent and high quality products.

Editors Walkiria S. Schlindwein is Associate Professor of Pharmaceutics at the School of Pharmacy, De Montfort University. Walkiria is the programme leader of two Postgraduate courses in Pharmaceutical Quality by Design. Mark Gibson is Director of AM PharmaServices Ltd. He is a practicing Pharmaceutical Consultant and was formerly with AstraZeneca.

Title Page 5

Copyright Page 6

Contents 7

List of Figures 15

List of Tables 21

List of Contributors 23

Advances in Pharmaceutical Technology: Series Preface 25

Preface 27

Chapter 1 Introduction to Quality by Design (QbD) 29

1.1 Introduction 29

1.2 Background 30

1.3 Science- and Risk-Based Approaches 32

1.4 ICH Q8–Q12 33

1.5 QbD Terminology 34

1.6 QbD Framework 35

1.7 QbD Application and Benefits 35

1.8 Regulatory Aspects 36

1.9 Summary 37

1.10 References 37

Chapter 2 Quality Risk Management (QRM) 39

2.1 Introduction 39

2.2 Overview of ICH Q9 41

2.2.1 Start QRM Process 43

2.2.2 Risk Assessment 43

2.2.3 Risk Control 44

2.2.4 Risk Review 44

2.3 Risk Management Tools 45

2.4 Practical Examples of Use for QbD 50

2.4.1 Case Study 54

2.4.2 Pre-work 54

2.4.3 Scoring Meeting 60

2.4.4 FMECA Tool 60

2.4.5 Risk Score 60

2.4.6 Detectability Score 62

2.4.7 Communication 63

2.5 Concluding Remarks 64

2.6 References 72

Chapter 3 Quality Systems and Knowledge Management 75

3.1 Introduction to Pharmaceutical Quality System 75

3.1.1 Knowledge Management – What Is It and Why Do We Need It? 75

3.2 The Regulatory Framework 76

3.2.1 Knowledge Management in the Context of Quality by Design (QbD) 76

3.2.2 Roles and Responsibilities for Quality System 77

3.2.3 Roles and Responsibilities for Knowledge Management 78

3.2.4 Implicit and Explicit Knowledge 78

3.3 The Documentation Challenge 79

3.4 From Data to Knowledge: An Example 84

3.5 Data Integrity 86

3.6 Quality Systems and Knowledge Management: Common Factors for Success 86

3.7 Summary 87

3.8 References 88

Chapter 4 Quality by Design (QbD) and the Development and Manufacture of Drug Substance 89

4.1 Introduction 89

4.2 ICH Q11 and Drug Substance Quality 90

4.2.1 Enhanced Approach 91

4.2.2 Impurities 91

4.2.3 Physical Properties of Drug Substance 92

4.3 Linear and Convergent Synthetic Chemistry Routes 93

4.4 Registered Starting Materials (RSMs) 95

4.5 Definition of an Appropriate Manufacturing Process 96

4.5.1 Crystallization, Isolation and Drying of APIs 96

4.5.2 Types of Crystallization 97

4.5.3 Design of Robust Cooling Crystallization 98

4.6 In-Line Process Analytical Technology and Crystallization Processes 106

4.6.1 Other Unit Operations 108

4.7 Applying the QbD Process 110

4.7.1 Quality Risk Assessment (QRA) 111

4.8 Design of Experiments (DoE) 115

4.9 Critical Process Parameters (CPPs) 116

4.10 Design Space 116

4.11 Control Strategy 117

4.12 References 119

Chapter 5 The Role of Excipients in Quality by Design (QbD) 125

5.1 Introduction 125

5.2 Quality of Design (QbD) 126

5.3 Design of Experiments (DoE) 128

5.4 Excipient Complexity 130

5.5 Composition 133

5.6 Drivers of Functionality or Performance 133

5.7 Limited Utility of Pharmacopoeial Attributes 134

5.8 Other Unspecified Attributes 135

5.9 Variability 135

5.10 Criticalities or Latent Conditions in the Finished Product 136

5.11 Direct or Indirect Impact of Excipient Variability 138

5.12 Control Strategy 139

5.13 Communication with Suppliers 140

5.14 Build in Compensatory Flexibility 141

5.15 Risk Assessment 141

5.16 Contingencies 142

5.17 References 142

Chapter 6 Development and Manufacture of Drug Product 145

6.1 Introduction 145

6.2 Applying QbD to Pharmaceutical Drug Product Development 147

6.3 Product Design Intent and the Target Product Profile (TPP) 148

6.4 The Quality Target Product Profile (QTPP) 154

6.5 Identifying the Critical Quality Attributes (CQAs) 156

6.6 Product Design and Identifying the Critical Material Attributes (CMAs) 161

6.7 Process Design and Identifying the Critical Process Parameters (CPPs) 164

6.8 Product and Process Optimisation 167

6.9 Design Space 173

6.10 Control Strategy 178

6.11 Continuous Improvement 181

6.12 Acknowledgements 182

6.13 References 182

Chapter 7 Design of Experiments 185

7.1 Introduction 185

7.2 Experimental Design in Action 186

7.3 The Curse of Variation 186

7.3.1 Signal-to-Noise Ratio 187

7.4 Fitting a Model 189

7.4.1 Summary of Fit 193

7.5 Parameter Estimates 193

7.6 Analysis of Variance 194

7.6.1 Reflection 196

7.7 ‘To Boldly Go’ – An Introduction to Managing Resource Constraints using DoE 197

7.8 The Motivation for DoE 198

7.8.1 How Does the Workshop Exercise Work? 199

7.8.2 DoE Saves the Day! 200

7.9 Classical Designs 201

7.9.1 How Do Resource Constraints Impact the Design Choice? 201

7.9.2 Resource Implications in Practice 201

7.10 Practical Workshop Design 202

7.10.1 Choice of Factors and Measurements 203

7.10.2 Data Collection and Choice of Design 203

7.10.3 Some Simple Data Visualization 203

7.10.4 Analysis of the Half Fraction 205

7.10.5 How to Interpret Prediction Profiles 205

7.10.6 Half Fraction and Alternate Half Fraction 206

7.10.7 Interaction Effects 206

7.10.8 Full Factorial 209

7.10.9 Central Composite Design 209

7.10.10 How Robust Is This DoE to Unexplained Variation? 209

7.11 How Does This Work? The Underpinning of Statistical Models for Variation 212

7.12 DoE and Cycles of Learning 215

7.13 Sequential Classical Designs and Definitive Screening Designs 217

7.14 Building a Simulation 218

7.14.1 Sequential design, Part 1: Screening Design (10 Runs) 219

7.14.2 Sequential Design, Part II: Optimization Design (26 Runs) 219

7.14.3 Definitive Screening Design 222

7.14.4 Robustness Design 222

7.14.5 Additional Challenges 225

7.15 Conclusion 225

7.16 Acknowledgements 226

7.17 References 226

Chapter 8 Multivariate Data Analysis (MVDA) 229

8.1 Introduction 229

8.2 Principal Component Analysis (PCA) 230

8.3 PCA Case Study: Raw Material Characterization using Particle Size Distribution Curves 232

8.3.1 Dataset Description 232

8.3.2 Fitting a PCA Model to the 45 Training Set Batches 233

8.3.3 Classification of the 13 Test Set Batches 234

8.3.4 Added Value from DoE to Select Spanning Batches 236

8.4 Partial Least Squares Projections to Latent Structures (PLS) 236

8.5 PLS Case Study: A Process Optimization Model 238

8.5.1 Dataset Description 238

8.5.2 PLS Modeling of 85-Samples SOVRING Subset 239

8.5.3 Looking into Cause-and-Effect Relationships 240

8.5.4 Making a SweetSpot Plot to Summarize the PLS Results 241

8.5.5 Using the PLS-DoE Model as a Basis to Define a Design Space and PARs for the SOVRING Process 243

8.5.6 Summary of SOVRING Application 245

8.6 Orthogonal PLS (OPLS® Multivariate Software) 245

8.7 Orthogonal PLS (OPLS® Multivariate Software) Case Study – Batch Evolution Modeling of a Chemical Batch Reaction 246

8.7.1 Dataset Description 246

8.7.2 Batch Evolution Modeling 246

8.8 Discussion 248

8.8.1 The PAT Initiative 248

8.8.2 What Are the Benefits of Using DoE? 249

8.8.3 QbD and Design Space 250

8.8.4 MVDA/DoE Is Needed to Accomplish PAT/QbD in Pharma 251

8.8.5 MVDA: A Way to Power up the CPV Application 251

8.9 References 252

Chapter 9 Process Analytical Technology (PAT) 255

9.1 Introduction 255

9.2 How PAT Enables Quality by Design (QbD) 257

9.3 The PAT Toolbox 257

9.4 Process Sensors and Process Analysers 257

9.4.1 Process Sensors – Univariate 261

9.4.2 Process Analysers – Multivariate 261

9.4.3 Infrared (IR) 261

9.4.4 Near Infrared (NIR) 266

9.4.5 Tunable Diode Laser Spectroscopy (TDLS) 267

9.4.6 Ultraviolet-Visible (UV-Vis) 267

9.4.7 Raman 267

9.4.8 Focused Beam Reflectance Measurements (FBRM) and Laser Diffraction 267

9.4.9 Particle Vision and Measurement (PVM) 267

9.4.10 X-Ray Fluorescence (XRF) 268

9.4.11 Imaging Technologies 268

9.5 Analyser Selection 268

9.6 Regulatory Requirements Related to PAT Applications 268

9.6.1 Europe 270

9.6.2 United States 270

9.7 PAT Used in Development 270

9.8 PAT Used in Manufacturing 271

9.9 PAT and Real Time Release Testing (RTRT) 273

9.10 PAT Implementation 273

9.11 Data Management 274

9.12 In-Line Process Monitoring with UV-Vis Spectroscopy: Case Study Example 275

9.13 References 281

Chapter 10 Analytical Method Design, Development, and Lifecycle Management 285

10.1 Introduction 285

10.2 Comparison of the Traditional Approach and the Enhanced QbD Approach 286

10.3 Details of the Enhanced QbD Approach 288

10.4 Defining Method Requirements 290

10.5 Designing and Developing the Method 292

10.6 Understanding the Impact of Method Parameters on Performance 294

10.7 Defining the Method Control Strategy and Validating the Method 295

10.8 Monitoring Routine Method Performance for Continual Improvement 296

10.9 Summary 297

10.10 Example Case Studies 298

10.10.1 Case Study 1 – Establishment of Robust Operating Ranges during Routine Method Use and Justifying the Method Control Strategy (Including SST Criteria) 298

10.10.2 Risk Assessment and Definition of Ranges 298

10.10.3 Experimental Design 299

10.10.4 Evaluate the DoE 300

10.10.5 Documenting Method Performance 302

10.10.6 Case Study 2 – Evaluation of the Ruggedness of a Dissolution Method for a Commercial Immediate Release Tablet Product 302

10.10.7 Case Study Acknowledgements 306

10.11 References 306

Chapter 11 Manufacturing and Process Controls 309

11.1 Introduction to Manufacturing and Facilities 309

11.2 Validation of Facilities and Equipment 310

11.2.1 The International Society for Pharmaceutical Engineering (ISPE) Baseline® Guide: Commissioning and Qualification 310

11.2.2 ASTM E2500-07: Standard Guide for Specification, Design, and Verification of Pharmaceutical and Biopharmaceutical Manufacturing Systems and Equipment 312

11.2.3 Science-Based Approach and Critical Aspects 313

11.2.4 Risk-Based Approach 314

11.2.5 System and Component Impact Assessments 316

11.2.6 URSs for Systems 318

11.2.7 Specification and Design 318

11.2.8 Verification 318

11.3 Drug Product Process Validation: A Lifecycle Approach 320

11.3.1 Stage 1: Process Design/Product Development 323

11.3.2 Stage 2: Process Qualification 326

11.3.3 Stage 3: Continued Process Verification 327

11.4 The Impact of QbD on Process Equipment Design and Pharmaceutical Manufacturing Processes 328

11.5 Introduction to Process Control in Pharmaceutical Manufacturing 330

11.6 Advanced Process Controls (APC) and Control Strategy 333

11.7 The Establishment of Continuous Manufacture 337

11.8 The Tablet Press as Part of a Continuous Tableting Line 340

11.9 Real-Time Release Testing and Continuous Quality Verification 344

11.10 Acknowledgments 345

11.11 References 345

Chapter 12 Regulatory Guidance 349

12.1 Introduction 349

12.2 The Common Technical Document (CTD) Format 350

12.2.1 Quality Target Product Profile (QTPP) and Critical Quality Attributes (CQAs) 352

12.2.2 Quality Risk Management (ICH Q9) 352

12.2.3 Product and Process Development (S.2.6 and P.2) 353

12.2.4 Control Strategy 354

12.2.5 Design Space (Optional) 355

12.3 Essential Reading 356

12.4 What Is Not Written, or Hidden, in the Guidance Documents? 357

12.5 Post-Approval Change 358

12.6 Summary 359

12.7 References 360

Index 363

Supplemental Images 366

EULA 378

| Erscheint lt. Verlag | 11.1.2018 |

|---|---|

| Reihe/Serie | Advances in Pharmaceutical Technology |

| Advances in Pharmaceutical Technology | Advances in Pharmaceutical Technology |

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie ► Technische Chemie |

| Technik | |

| Schlagworte | chemical engineering • Chemical Engineering Fundamentals • Chemie • Chemische Verfahrenstechnik • Chemistry • examples of QbD • Grundlagen der Chemischen Verfahrenstechnik • Guide to QbD for pharmaceutical industry • Guide to Quality by Design for pharmaceutical industry • holistic approach to pharmaceutical manufacturing • Mark Gibson • Medizinische Chemie • Pharmaceutical & Medicinal Chemistry • Pharmaceutical Quality by Design A Practical Approach • Pharmazeutische Chemie • Pharmazeutische u. Medizinische Chemie • principles of QbD • principles of quality by design • QbD and FDA • QbD and manufacturing active pharmaceutical ingredients • QbD and risk management tools. Quality by Design and risk management analysis • Qualitätssicherung • Qualitätssicherung in der Chemie • Quality assurance • quality by design and design of experiments • quality by design and knowledge management • quality by design and manufacture of drug substance • quality by design and multivariate analysis • quality by design and the role of excipients • Walkiria S. Schlindwein |

| ISBN-10 | 1-118-89522-3 / 1118895223 |

| ISBN-13 | 978-1-118-89522-1 / 9781118895221 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: PDF (Portable Document Format)

Mit einem festen Seitenlayout eignet sich die PDF besonders für Fachbücher mit Spalten, Tabellen und Abbildungen. Eine PDF kann auf fast allen Geräten angezeigt werden, ist aber für kleine Displays (Smartphone, eReader) nur eingeschränkt geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich