Separation and Purification Technologies in Biorefineries (eBook)

John Wiley & Sons (Verlag)

978-1-118-49346-5 (ISBN)

This book presents a comprehensive overview focused specifically on the present state, future challenges and opportunities for separation and purification methods and technologies in biorefineries.

Topics covered include:

Equilibrium Separations: Distillation, liquid-liquid extraction and supercritical fluid extraction.

Affinity-Based Separations: Adsorption, ion exchange, and simulated moving bed technologies.

Membrane Based Separations: Microfiltration, ultrafiltration and diafiltration, nanofiltration, membrane pervaporation, and membrane distillation.

Solid-liquid Separations: Conventional filtration and solid-liquid extraction.

Hybrid/Integrated Reaction-Separation Systems: Membrane bioreactors, extractive fermentation, reactive distillation and reactive absorption.

For each of these processes, the fundamental principles and design aspects are presented, followed by a detailed discussion and specific examples of applications in biorefineries. Each chapter also considers the market needs, industrial challenges, future opportunities, and economic importance of the separation and purification methods. The book concludes with a series of detailed case studies including cellulosic bioethanol production, extraction of algae oil from microalgae, and production of biopolymers.

Separation and Purification Technologies in Biorefineries is an essential resource for scientists and engineers, as well as researchers and academics working in the broader conventional and emerging bio-based products industry, including biomaterials, biochemicals, biofuels and bioenergy.

Editors:

Shri Ramaswamy

Department of Bioproducts and Biosystems Engineering, University of Minnesota, USA

Hua-Jiang Huang

Department of Bioproducts and Biosystems Engineering, University of Minnesota, USA

Bandaru V. Ramarao

Department of Paper & Bioprocess Engineering, State University of New York College of Environmental Science and Forestry, USA

Separation and purification processes play a critical role in biorefineries and their optimal selection, design and operation to maximise product yields and improve overall process efficiency. Separations and purifications are necessary for upstream processes as well as in maximising and improving product recovery in downstream processes. These processes account for a significant fraction of the total capital and operating costs and also are highly energy intensive. Consequently, a better understanding of separation and purification processes, current and possible alternative and novel advanced methods is essential for achieving the overall techno-economic feasibility and commercial success of sustainable biorefineries. This book presents a comprehensive overview focused specifically on the present state, future challenges and opportunities for separation and purification methods and technologies in biorefineries. Topics covered include: Equilibrium Separations: Distillation, liquid-liquid extraction and supercritical fluid extraction. Affinity-Based Separations: Adsorption, ion exchange, and simulated moving bed technologies. Membrane Based Separations: Microfiltration, ultrafiltration and diafiltration, nanofiltration, membrane pervaporation, and membrane distillation. Solid-liquid Separations: Conventional filtration and solid-liquid extraction. Hybrid/Integrated Reaction-Separation Systems: Membrane bioreactors, extractive fermentation, reactive distillation and reactive absorption. For each of these processes, the fundamental principles and design aspects are presented, followed by a detailed discussion and specific examples of applications in biorefineries. Each chapter also considers the market needs, industrial challenges, future opportunities, and economic importance of the separation and purification methods. The book concludes with a series of detailed case studies including cellulosic bioethanol production, extraction of algae oil from microalgae, and production of biopolymers. Separation and Purification Technologies in Biorefineries is an essential resource for scientists and engineers, as well as researchers and academics working in the broader conventional and emerging bio-based products industry, including biomaterials, biochemicals, biofuels and bioenergy.

Shri Ramaswamy, Department of Bioproducts and Biosystems Engineering, University of Minnesota, USA. Hua-Jiang Huang, Department of Bioproducts and Biosystems Engineering, University of Minnesota, USA. Bandaru V. Ramarao, Department of Paper & Bioprocess Engineering, State University of New York College of Environmental Science and Forestry, USA.

Chapter 1

Overview of Biomass Conversion Processes and Separation and Purification Technologies in Biorefineries

Hua-Jiang Huang and Shri Ramaswamy

Department of Bioproducts and Biosystems Engineering, University of Minnesota, USA

1.1 Introduction

There has been an increasing interest in conversion of biomass to biofuels, energy and chemicals due to increase in global demand, price and decrease in potential availability of crude oil, the need for energy independence and energy security, and the need for reduction in greenhouse gases emission from fossil fuel contributing to global climate change, and so forth.

Biomass feedstock suitable for producing biofuels, energy and co-products can be starchy biomass (e.g., corn/wheat kernel, cassava), sugarcane and sugar beet, ligocellulosic biomass including agricultural residues (e.g., corn stover, crop residues such as wheat straw and barley straw, and sugar cane bagasse), forest wastes, fast-growing trees such as hybrid poplar and willow, fast-growing herbaceous crops such as switchgrass and alfalfa, oily plants such as soybean and rapeseed, microalgae, waste cooking oil, animal manure, as well as municipal solid waste. The total amount of biomass feedstock available is huge. In the United States, based on the estimation by U.S. Department of Energy (U.S. Department of Energy 2011), total potential biomass resource is about 258 (baseline)–340 (high-yield scenario) million dry tons in 2012. Potential supplies at a forest roadside or farmgate price of $60 per dry ton range from 602 to 1009 million dry tons by 2022 and from about 767 to 1305 million dry tons by 2030, depending on the assumptions for energy crop productivity (1% to 4% annual increase over current yields). This estimate excludes resources that are currently being used, such as corn grain and woody biomass used in the forest products industry. Worldwide, the biomass availability is also significantly high of the order of 5.0 billion tons per year (Bauen et al. 2009; U.S. Department of Energy 2011).

Biofuels made from starchy crops, sugar plants as well as vegetable oils are usually called first-generation biofuels; for example, bioethanol produced from maize, starch, or sugar via fermentation, biodiesel from soybean oil, rapeseed oil, palm oil, or other plant oil by transesterification. Biogas from anaerobic digestion of waste streams also belongs to the first-generation biofuels. As the first-generation biofuels produced from food crops competes with food production and supply, and biogas can only be produced in small quantities, the first-generation biofuels alone generally cannot meet our energy requirements. Biofuels such as cellulosic ethanol made from lignocellulosic biomass such as woody crops, fast-growing trees and herbaceous crops, agricultural residues and forestry waste are referred to as the second-generation biofuels. The focus for second-generation biofuels was primarily ethanol. Unlike the first-generation biofuels, the second-generation biofuels are based on non-food crops and other lignocellulosic biomass; it can also bring about significant reduction in greenhouse gas emissions as well as reduction in fossil fuel use. The third-generation biofuels are made from genetically modified energy crops that may be carbon-neutral, biofuels from algae, or biofuels directly produced from microorganisms or using advances in biochemistry. Fourth-generation biofuels have also been suggested, which are carbon negative—they consume more carbon than they generate during their entire life cycle. Examples of this could be carbon-fixing plants such as low input high-diversity perennial grasses (Tilman, Hill, and Lehman 2006).

A biorefinery is a facility to convert biomass to bioproducts including bioenergy (fuels, heat and power) and diverse array of co-products (including materials and chemicals) (Huang et al. 2008; Huang and Ramaswamy 2012). The biorefinery concept is similar to today's petroleum refinery, which produces multiple fuels and products from petroleum (http://www.nrel.gov/biomass/biorefinery.html). Biorefinery can be divided into two basic conversion platforms: biochemical conversions, and thermo-chemical conversions. A biorefinery can also be a combination of both biochemical and thermo-chemical conversion approaches. Biochemical conversions of biomass using enzymes and microorganisms (yeast and bacteria) are often referred to as “sugar-platform” conversions, where biomass is firstly pretreated and hydrolyzed to mono-sugars: glucose, xylose, arabinose, galactose, and mannose, and so forth. The mono-sugars are then fermented or digested to biofuels such as bioethanol and biobutanol, or chemicals such as lactic acid and succinic acid, depending on the biocatalysts used. Thermo-chemical conversion of biomass includes biomass combustion for heat and power, pyrolysis for bio-oil and biochar, hydrothermal liquefaction to bio-oils as major product, and biomass gasification to syngas. Syngas (mainly CO and H2) from biomass gasification can be further synthesized into a wide range of different fuels and chemicals under different catalysts and operating conditions; biomass gasification or “syngas platform” represents the major thermo-chemical platform. In addition to these basic thermo-chemical conversions, there are a variety of other chemical conversion processes such as conversion of oil-containing biomass such as soybean and microalgae for biodiesel, and the conversion of building block chemicals such as lactic acid to its corresponding commodities, chemicals, polymers and materials.

This chapter provides an overview of the separation and purification technologies in biorefineries for producing bioproducts including biofuels, bioenergy, biochemicals and materials, with more emphasis on lignocelluose biorefineries.

1.2 Biochemical conversion biorefineries

In the biochemical conversion biorefineries or “sugar platforms,” biomass is subjected to hydrolysis and saccharification and then the resulting sugars, including hexoses (glucose, mannose, and galactose) and pentoses (xylose, arabinose) are converted to biofuels such as ethanol and butanol, chemicals, and materials.

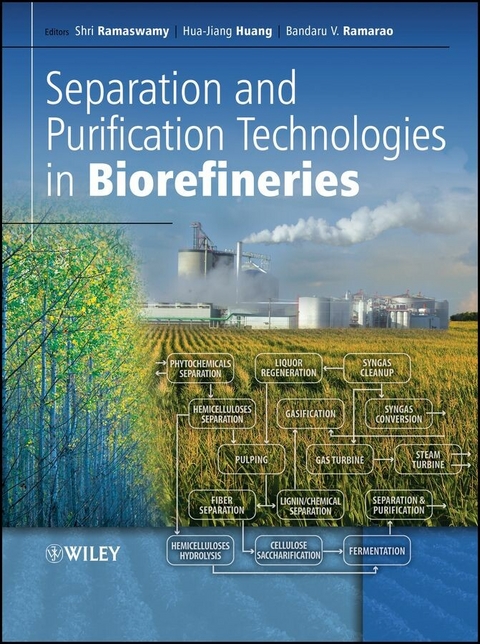

As an example, the basic process for conversion of cellulosic biomass to fuel ethanol is shown in Figure 1.1, which mainly consists of the following eight major process areas (Aden et al. 2002):

Figure 1.1 Simplified process block diagram of basic lignocellulose to ethanol biorefinery (Aden et al. 2002; Huang et al....

| Erscheint lt. Verlag | 4.2.2013 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie ► Technische Chemie |

| Technik ► Elektrotechnik / Energietechnik | |

| Schlagworte | Agriculture • Biorenewable Resources • chemical engineering • Chemie • Chemische Verfahrenstechnik • Chemistry • Grüne Chemie • Grüne Chemie • Landwirtschaft • Nachhaltige u. Grüne Chemie • Nachhaltige u. Grüne Chemie • Nachwachsende Rohstoffe • Separations • Separation science, purification technology, biorefineries, biomass conversion processes, equilibrium based separation processes, distillation, liquid-liquid extraction, supercritical fluid extraction, affinity-based separation technologies, adsorption, ion exchange, simulated moving bed technology, chromatography, membrane separation, microfiltration, ultrafiltration, diafiltration, nanofiltration, membrane pervaporation, membrane distillation, solid-liquid separations, conventional filtration, solid-liqui • Stofftrennverfahren • Sustainable Chemistry & Green Chemistry • Trennverfahren |

| ISBN-10 | 1-118-49346-X / 111849346X |

| ISBN-13 | 978-1-118-49346-5 / 9781118493465 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich