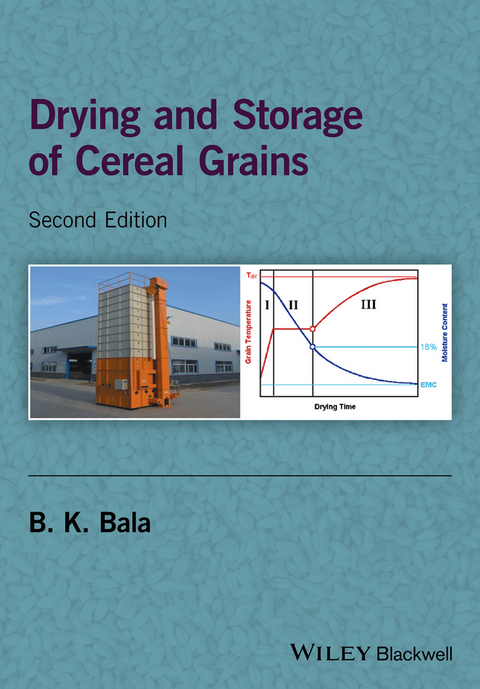

Drying and Storage of Cereal Grains (eBook)

John Wiley & Sons (Verlag)

978-1-119-12424-5 (ISBN)

Finite Element Analysis and Computational Fluid Dynamics have been introduced in modelling and simulation of drying and storage systems, these techniques are expected to dominate the future research and development of drying and storages, and should reduce losses and improve the quality of agricultural products, enhancing food security globally.

Drying and Storage of Cereal Grains, Second Edition, covers the wide spectrum of drying and storage methods applied to economically important cereal produce, providingnumerical examples for better understanding the complexity in drying and storage systems through modelling and simulation, aiding design and management of drying and storage systems. Chapters 1 to 8 look at air and grain moisture equilibria, psychrometry, physical and thermal properties of cereal grains, principles of air flow, and provide detailed analyses of grain drying.Chapters 9 to 13 focus on temperature and moisture in grain storages, and provide comprehensive treatment of modern grain storage systems. The book also includes a number of unsolved problems at the end of each chapter for further practice.

This revised second edition includes new sections on -

- heat of sorption

- finite element modeling of single kernel

- CFD modeling of fluidized bed drying

- exergy analysis and neural network modeling

- numerical solution of two dimensional temperature and moisture changes in stored grain

This book will provide students in agricultural engineering and food engineering with a wide spectrum of drying and storage studies previously unavailable in a single monograph. It will also serve as an excellent reference for practicing agricultural engineers, food engineers and food technologists.

B K Bala, Department of Agro Product Processing Technology, Jessore University of Science and Technology, Bangladesh.

Finite Element Analysis and Computational Fluid Dynamics have been introduced in modelling and simulation of drying and storage systems, these techniques are expected to dominate the future research and development of drying and storages, and should reduce losses and improve the quality of agricultural products, enhancing food security globally. Drying and Storage of Cereal Grains, Second Edition, covers the wide spectrum of drying and storage methods applied to economically important cereal produce, providingnumerical examples for better understanding the complexity in drying and storage systems through modelling and simulation, aiding design and management of drying and storage systems. Chapters 1 to 8 look at air and grain moisture equilibria, psychrometry, physical and thermal properties of cereal grains, principles of air flow, and provide detailed analyses of grain drying.Chapters 9 to 13 focus on temperature and moisture in grain storages, and provide comprehensive treatment of modern grain storage systems. The book also includes a number of unsolved problems at the end of each chapter for further practice. This revised second edition includes new sections on - heat of sorption finite element modeling of single kernel CFD modeling of fluidized bed drying exergy analysis and neural network modeling numerical solution of two dimensional temperature and moisture changes in stored grain This book will provide students in agricultural engineering and food engineering with a wide spectrum of drying and storage studies previously unavailable in a single monograph. It will also serve as an excellent reference for practicing agricultural engineers, food engineers and food technologists.

B K Bala, Department of Agro Product Processing Technology, Jessore University of Science and Technology, Bangladesh.

Title Page 5

Copyright 6

Contents 7

Foreword to the Second Edition 13

Foreword to the First Edition 15

Preface 17

Chapter 1 Principles of Drying 19

1.1 Introduction 19

1.2 Losses of Crops 20

1.3 Importance of Drying 20

1.4 Principles of Drying 20

Reference 21

Further Reading 21

Chapter 2 Moisture Contents and Equilibrium Moisture Content Models 23

2.1 Introduction 23

2.2 Moisture Content Representation 23

2.3 Determination of Moisture Content 25

2.3.1 Direct Methods 26

2.3.2 Indirect Methods 28

2.4 Grain Sampling 30

2.5 Equilibrium Moisture Content 30

2.6 Determination of Static Equilibrium Moisture Content 35

2.7 Static Equilibrium Moisture Content Models 38

2.8 Net Isosteric Heat of Sorption 40

Exercises 46

References 46

Chapter 3 Psychrometry 49

3.1 Introduction 49

3.2 Psychrometric Terms 49

3.2.1 Humidity Ratio 50

3.2.2 Relative Humidity 50

3.2.3 Specific Volume 51

3.2.4 Vapour Pressure 51

3.2.5 Dry Bulb Temperature 51

3.2.6 Dew Point Temperature 51

3.2.7 Wet Bulb Temperature 52

3.2.8 Enthalpy 52

3.2.9 Adiabatic Wet Bulb Temperature 53

3.2.10 Psychrometric Wet Bulb Temperature 54

3.3 Construction of Psychrometric Chart 56

3.4 Use of Psychrometric Chart 57

3.4.1 Sensible Heating and Cooling 57

3.4.2 Heating with Humidification 58

3.4.3 Cooling with Humidification 59

3.4.4 Cooling with Dehumidification 59

3.4.5 Drying 60

3.4.6 Mixing of Air Streams 61

3.4.7 Heat Addition with Air Mixing 63

3.4.8 Drying with Recirculation 64

Exercises 70

References 72

Further Reading 72

Chapter 4 Physical and Thermal Properties of Cereal Grains 73

4.1 Introduction 73

4.2 Structure of Cereal Grains 73

4.3 Physical Dimensions 73

4.4 1000 Grain Weight 74

4.5 Bulk Density 75

4.6 Shrinkage 75

4.7 Friction 76

4.7.1 Angle of Internal Friction and Angle of Repose 77

4.7.2 Coefficient of Friction 77

4.8 Specific Heat 79

4.9 Thermal Conductivity 81

4.9.1 Theory 81

4.9.2 Apparatus and Measurement 83

4.10 Latent Heat of Vaporization of Grain Moisture 84

4.10.1 Determination of Latent Heat of Vaporization of a Grain 85

4.11 Heat Transfer Coefficient of Grain Bed 87

4.11.1 Dimensional Analysis 88

4.11.2 Comparison of Theory and Experiment 88

4.11.3 Determination of Volumetric Heat Transfer Coefficient 90

Exercises 94

References 96

Further Reading 98

Chapter 5 Airflow Resistance and Fans 99

5.1 Airflow Resistance 99

5.1.1 Non-linear Airflow Analysis 101

5.2 Fans 109

5.2.1 Fan Performance 110

5.2.2 Centrifugal Fan Laws 113

5.2.3 Fan Selection 115

5.2.4 Effect of Change in Fan Speed 116

5.2.5 Effect of Change in Speed and System Resistance 117

5.2.6 Fans in Series and Parallel 117

5.3 Duct Design for On-Floor Drying and Storage System 120

Exercises 121

References 123

Chapter 6 Thin Layer Drying of Cereal Grains 125

6.1 Theory 125

6.2 Thin Layer Drying Equations 127

6.2.1 Empirical Drying Equations 127

6.2.2 Theoretical Drying Equations 128

6.2.3 Semi-Theoretical Drying Equations 131

6.2.4 Comparison of Thin Layer Drying Equations 132

6.3 Development of Thin Layer Drying Equations 134

6.3.1 Drying Rate 137

6.4 Drying Parameters 137

6.4.1 Drying Rate Constant and Diffusion Coefficient 138

6.4.2 Dynamic Equilibrium Moisture Content 145

6.5 Finite Element Modelling of Single Kernel 151

6.5.1 Finite Element Model Formulation 151

6.5.2 Finite Difference Solution in Time 156

6.5.3 Discretization of the Domain 156

Exercises 158

References 160

Further Reading 163

Chapter 7 Deep-Bed and Continuous Flow Drying 165

7.1 Introduction 165

7.2 Deep-Bed Drying Models 165

7.2.1 Logarithmic Models 166

7.2.2 Partial Differential Equation Models 166

7.2.3 Comparison of Deep-Bed Drying Models 167

7.3 Development of Models for Deep-Bed Drying 167

7.3.1 Logarithmic Model 168

7.3.2 Partial Differential Equation Model 174

7.3.3 Method of Solution 178

7.3.4 Condensation Procedure 179

7.3.5 Sensitivity Analysis 187

7.3.6 Comparison of Simulated Drying with Experimental Results 187

7.3.7 Comparison of Direct, Indirect and Recirculating Direct Fired Drying 188

7.4 Development of Models for Continuous Flow Drying 189

7.4.1 Crossflow Model 191

7.4.2 Fluidized Bed Drying Model 198

7.5 CFD Modelling of Fluidized Bed Drying 203

7.5.1 Continuity Equation 203

7.5.2 Momentum Conservation Equations 204

7.5.3 Energy Conservation Equation 204

7.5.4 User-Defined Scheme (UDS) 205

7.5.5 CFD Analysis 205

Exercises 208

References 211

Further Reading 212

Chapter 8 Grain Drying Systems 213

8.1 Introduction 213

8.2 Solar Drying Systems 213

8.3 Batch Drying Systems 217

8.4 Continuous-Flow Drying Systems 218

8.4.1 Crossflow Dryer 218

8.4.2 Concurrent Flow Dryer 218

8.4.3 Counterflow Dryer 220

8.5 Safe Temperature for Drying Grain 220

8.6 Hydrothermal Stresses during Drying 221

8.7 Energy and Exergy Analysis of Drying Process 222

8.7.1 Drying Efficiency 223

8.7.2 Exergy Analysis through the Analysis of Second Law of Thermodynamics 223

8.8 Neural Network Modelling 224

8.8.1 Structure of ANN Model 225

8.8.2 Training of ANN Model 226

8.9 Selection of Dryers 227

Exercises 229

References 230

Further Reading 231

Chapter 9 Principles of Storage 233

9.1 Introduction 233

9.2 Principles of Storage 233

9.3 Interrelations of Physical, Chemical and Biological Variables in the Deterioration of Stored Grains 236

9.4 Computer Simulation Modelling for Stored Grain Pest Management 237

References 238

Further Reading 239

Chapter 10 Temperature and Moisture Changes During Storage 241

10.1 Introduction 241

10.2 Qualitative Analysis of Moisture Changes of Stored Grains in Cylindrical Bins 241

10.3 Temperature Changes in Stored Grains 243

10.4 Temperature Prediction 243

10.4.1 The Differential Equation of Heat Conduction in Cylindrical Coordinate System 244

10.4.2 Numerical Method 245

10.5 Numerical Solution of One-Dimensional Heat Flow 245

10.6 Numerical Solution of Two-Dimensional Heat and Moisture Flow 250

10.6.1 Heat Transfer Equation 251

10.6.2 Mass Transfer Equation 252

10.7 Simultaneous Momentum, Heat and Mass Transfer during Storage 267

10.7.1 The Energy Balance Equation 268

10.7.2 The Mass Balance Equation 269

10.7.3 The Momentum Balance Equation 269

10.7.4 Finite Difference Formulation 270

10.8 CFD Modelling of Grain Storage Systems 276

10.8.1 Continuity Equation 276

10.8.2 Momentum Conservation Equations 276

10.8.3 Energy Conservation Equation 276

10.8.4 User-Defined Function 276

Exercises 278

References 280

Further Reading 280

Chapter 11 Fungi, Insects and Other Organisms Associated with Stored Grain 281

11.1 Introduction 281

11.2 Fungi 281

11.2.1 Field Fungi 283

11.2.2 Intermediate Fungi 283

11.2.3 Storage Fungi 283

11.3 Insects 285

11.3.1 Insect Species 286

11.3.2 Grain Temperature and Moisture Content 287

11.4 Mites 288

11.5 Rodents 288

11.6 Respiration and Heating 288

11.7 Control Methods 289

References 290

Further Reading 290

Chapter 12 Design of Grain Storages 291

12.1 Introduction 291

12.2 Structural Requirements 291

12.2.1 Janssen Equation 291

12.2.2 Rankine Equation 295

12.2.3 Airy Equation 296

12.3 Construction Materials 298

Exercises 306

References 306

Chapter 13 Grain Storage Systems 307

13.1 Introduction 307

13.2 Traditional Storage Systems 308

13.3 Modern Storage Systems 308

13.3.1 Bagged Storage System 308

13.3.2 Silo Storage System 309

13.3.3 Airtight Grain Storage 310

13.3.4 Aerated Storage System 315

13.3.5 Low-Temperature Storage System (Grain Chilling by Refrigeration) 319

13.3.6 Controlled Atmosphere Storage Systems 322

13.3.7 Damp Grain Storage System with Chemicals 324

References 328

Further Reading 331

Appendix A: Finite Difference Approximation 333

Appendix B: Gaussian Elimination Method 335

Appendix C: Finite Element Method 339

References 341

Appendix D: Computational Fluid Dynamics 343

Further Reading 349

Index 351

EULA 354

| Erscheint lt. Verlag | 4.11.2016 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Biologie |

| Technik ► Lebensmitteltechnologie | |

| Weitere Fachgebiete ► Land- / Forstwirtschaft / Fischerei | |

| Schlagworte | Agriculture • air flow • Backwaren, Getreideerzeugnisse • Bakery & Cereals • cereal • CFD • crops • drying • Feldfrüchte • Feldfrüchte • finite element analysis • Food Quality Assurance • Food Science & Technology • Grain • Landwirtschaft • Lebensmittelforschung u. -technologie • Lebensmittel / Qualitätskontrolle • Lebensmittel / Qualitätskontrolle • Moisture • Psychrometry • Storage • Temperature • thermal |

| ISBN-10 | 1-119-12424-7 / 1119124247 |

| ISBN-13 | 978-1-119-12424-5 / 9781119124245 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: PDF (Portable Document Format)

Mit einem festen Seitenlayout eignet sich die PDF besonders für Fachbücher mit Spalten, Tabellen und Abbildungen. Eine PDF kann auf fast allen Geräten angezeigt werden, ist aber für kleine Displays (Smartphone, eReader) nur eingeschränkt geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich