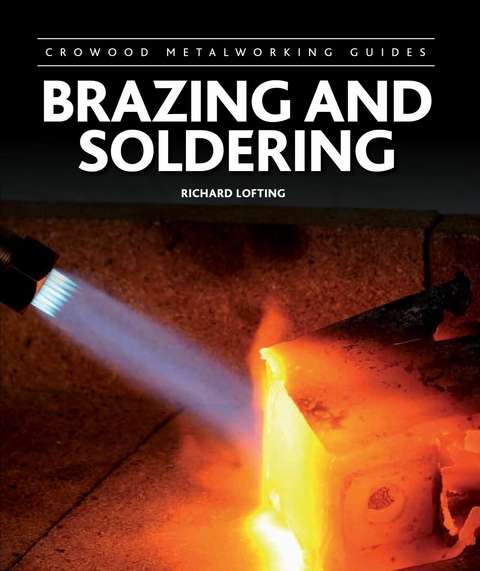

Brazing and Soldering (eBook)

394 Seiten

Crowood (Verlag)

978-1-84797-837-0 (ISBN)

Brazing and soldering are essential metal joining techniques for a range of jobs in the workshop. This new practical guide will introduce you to the methods and show you how to enhance these skills safely and effectively, with step-by-step photography throughout. Included in this new book is advice on equipment and building a brazing hearth; an overview of alloys and fluxes; lead loading, body and electrical soldering and pickling and cleaning. The main brazing and soldering types are also covered including soft soldering, silver soldering and brazing. There is also a range of case studies to show practical technique applications.

For any soldering or brazing operation a form of heat will be required.

2 Soldering Irons and Blowlamps

At the very heart of soldering, or brazing for that matter, a heat source is required to bring things up to the melting temperature of the filler rod being used. In this book, we are concentrating on the options available in a general or home workshop, although in industry many different ways are employed to heat components for soldering and brazing. An example is the induction coil, whereby an electric current is passed through a coil, which in turn induces heat from within into the items to be joined, making it a quick and efficient method, but one that is only cost-effective when used for mass-production. The basic requirement of the heat source is to bring the component parts and the joint area up to the melting temperature of the solder or brazing rod fairly quickly so as to avoid oxide formation. Soldering in some forms and brazing are carried out with just a flame, but for normal soft soldering a soldering iron will usually be needed. This will give an efficient transfer of heat to the item being soldered, with the minimum of oxide formation.

For the larger soft soldering job, large electric soldering irons are available, up to 200–300 watts.

Small electric soldering irons are the correct tool for electrical soldering; the miniature ones, typically 9 watts, are ideal for circuit board work.

Gas-powered blowlamps come in all shapes and sizes,from this small general-purpose type through to largergas torches, which are powered by industrial-sizedcylinders.

THE TRADITIONAL SOLDERING IRON

Historically, a soldering iron, with the working bit usually made of copper riveted to an iron shaft with a wooden handle, was heated in a coke or coal fire, with the soldering iron placed inside a piece of iron pipe or similar. This avoided the corrosive effects of the fire attacking the soldering iron bit and consequently the joint to be made, and also lessened the formation of oxides on the soldering iron away from the direct heat of the fire. Once the bit of the soldering iron was up to the required temperature to melt the solder, it would be mechanically cleaned and then dipped into the flux before applying solder to ‘tin’ the tip of the soldering iron. During the soldering process, as the heat from the soldering iron was given up into whatever item was being soldered, the soldering iron would require reheating in the fire before carrying on with the job. This may have taken several reheats until completion of the work. If more than one soldering iron was available, one iron would be heating while the other was being used. Once paraffin was freely available and the use of pressurized blowlamps was in vogue, soldering became easier and more portable, with repair work being undertaken on site rather than having to be taken to the coke furnace, or a furnace having to be set up on site. This was especially welcomed with lead work being common on roofs during this period, and water and drainage pipes also being made from lead, which lends itself to easy soldering, making watertight joints.

Before propane and butane torches, the paraffin blowlamp was the main heating source for soldering. This entailed heating the torch itself to vaporize the paraffin. Once hot enough and alight, the paraffin was pressurized by the built-in pump, creating a hot flame. Enough heat was available for small silver soldering jobs, but not quite enough for brazing.

Copper soldering irons were available in many shapes and sizes for use with the paraffin blowlamp. Of course, these can still be used with its modern gas equivalent.

Using copper soldering irons is straightforward. The soldering iron is heated by the flame away from the tip. When hot enough, the flux will bubble, indicating it is time to add the solder to tin the iron.

To use the iron successfully, the tip needs to be tinned adequately with solder.

SOLDERING IRONS

When undertaking soldering work with a soldering iron, although the temperature of the soldering iron is important, it is imperative to select the right size of bit. Too small and the heat will be lost too quickly. This will mean that as the heat is drawn into the object being soldered, either not enough heat will be available to complete the joint in one go, or the soldering iron will require frequent reheating to do the job properly. A large soldering iron bit will retain more heat for longer and is ideal for the larger job, but will require more time to heat up initially and at subsequent reheating, so will consume more fuel to carry out the same job.

ELECTRICAL SOLDERING IRONS

The above paragraph is just as relevant when applied to the electrical soldering iron. The only difference is that the heating coil within the soldering iron will not be able to keep up with the heat output that is required for the job in hand and consequently the solder will solidify on the tip of the iron. The only remedy here is to use a bigger wattage soldering iron. Electrical soldering irons are rated by the wattage that they consume, from the small ones with a wattage of 8 or 9 watts for fine electrical/electronic soldering, up to large ones of 120 watts or so capable of soldering sheet metal. Soldering irons are now available with instant heat being available as soon as they are switched on and upon release of the switch go off again. These are fine for where intermittent work is being carried out, saving power.

For very fine electrical soldering a small soldering iron is needed. This one is only 9 watts and can get in some very tight spaces.

For heavier work, larger electric soldering irons are available. The front two are 60-watt irons, the one at the back is 240 watts.

GAS-POWERED SOLDERING IRONS

Where more heat is required for the larger job, or the operation is being carried out far from an electrical power source, a gas-heated soldering iron should cover your needs. These work by the back of the soldering bit being heated by a gas flame. Some gas torches are adaptable to this mode of operation by the addition of a purpose-made adapter and a specially designed bit to fit it. This heats the iron throughout the entire operation. The heat input is easily varied to suit the job by adjusting the flame and different-sized bits are readily available.

To avoid having to keep reheating the iron, propane-heated soldering irons are available. Once the soldering temperature has been reached, continuous soldering can be undertaken without having to keep reheating.

BUTANE-POWERED SOLDERING IRON

One innovative product to come on the market over the last few years is the butane-powered blowtorch/soldering iron. The design incorporates a refillable gas cartridge in the handle of the device with a small blowtorch at the front end. The fancy ones incorporate a piezo crystal lighting device so that the whole thing is self-contained and does not require matches to light it. Various attachments are usually supplied in a blow-moulded plastic case, one of which is a soldering iron bit. Some just heat the back of the iron’s bit with the flame of the blowtorch, but the more sophisticated models have an inbuilt catalyser, which produces heat from the gas without a flame. This heats the back of the soldering iron bit instead of a bare flame, giving greater efficiency and therefore longer use between gas refills. The process when using a catalyst is to light the blowtorch as usual with the ignition device until the catalyst is sufficiently warm. The flame is then extinguished, usually by a mobile shutter that momentarily cuts across the gas flow, and the gas burns without a flame as it interacts with the catalyst.

A neat kit containing everything for the small soldering job – a butane-powered blowlamp, with various soldering bits, electrical solder and a tip cleaning sponge, all in a carrying case.

Filling of the gas canister is simple. All that is required is a butane lighter refill canister available from most large supermarkets or tobacconists, then selecting the right adapter to go between the refill canister and the blowtorch filling orifice. With the refill canister held with the filler down, press the two together, which will allow the liquid butane in the canister to flow into the blowtorch cartridge, until the pressure of both equalizes. For obvious reasons, all gas filling operations need to be done in the open air and of course well away from any sources of ignition, such as naked flames or pilot lights.

With these soldering and air heating bits all aspects of light soldering are catered for.

This type of butane torch is ideal for small heating jobs without the soldering iron attachment, just using it as a gas blowlamp.

The same torch with the soldering iron attachment; here the tip is heated with the aid of the built-in catalyst, converting the gas to heat without a flame. As there are no wires, it is fully portable.

CARE OF THE TIP

As has been observed in this book, when heating any metal it has the effect of increasing the natural oxidation on the metal’s surface. The bit on the soldering iron is no exception, hence the importance of properly tinning the bit in the first place and sub-sequently making sure that the tinning is in good order as you proceed during soldering. Apart from the tip oxidizing, interactions between the solder used and the soldering iron’s tip can readily occur. This usually takes the form of depletion of...

| Erscheint lt. Verlag | 31.3.2015 |

|---|---|

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Heimwerken / Do it yourself |

| Sachbuch/Ratgeber ► Freizeit / Hobby ► Kreatives Gestalten | |

| Technik ► Maschinenbau | |

| Wirtschaft | |

| ISBN-10 | 1-84797-837-1 / 1847978371 |

| ISBN-13 | 978-1-84797-837-0 / 9781847978370 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich