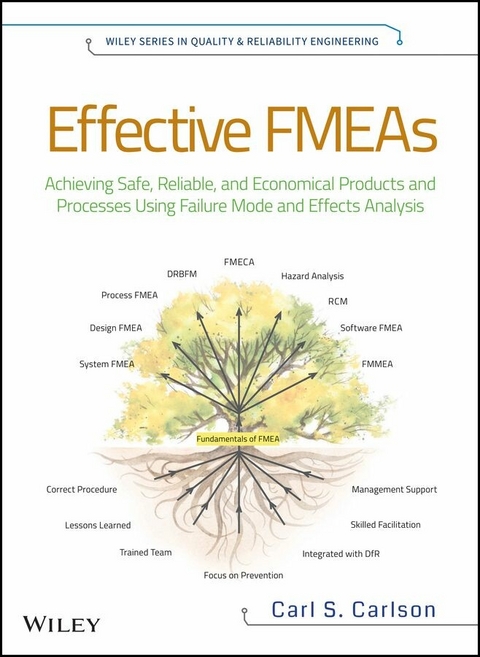

Effective FMEAs (eBook)

John Wiley & Sons (Verlag)

978-1-118-31258-2 (ISBN)

Outlines the correct procedures for doing FMEAs and how to successfully apply them in design, development, manufacturing, and service applications

There are a myriad of quality and reliability tools available to corporations worldwide, but the one that shows up consistently in company after company is Failure Mode and Effects Analysis (FMEA). Effective FMEAs takes the best practices from hundreds of companies and thousands of FMEA applications and presents streamlined procedures for veteran FMEA practitioners, novices, and everyone in between.

Written from an applications viewpoint-with many examples, detailed case studies, study problems, and tips included-the book covers the most common types of FMEAs, including System FMEAs, Design FMEAs, Process FMEAs, Maintenance FMEAs, Software FMEAs, and others. It also presents chapters on Fault Tree Analysis, Design Review Based on Failure Mode (DRBFM), Reliability-Centered Maintenance (RCM), Hazard Analysis, and FMECA (which adds criticality analysis to FMEA).

With extensive study problems and a companion Solutions Manual, this book is an ideal resource for academic curricula, as well as for applications in industry. In addition, Effective FMEAs covers:

-

The basics of FMEAs and risk assessment

-

How to apply key factors for effective FMEAs and prevent the most common errors

-

What is needed to provide excellent FMEA facilitation

-

Implementing a 'best practice' FMEA process

Everyone wants to support the accomplishment of safe and trouble-free products and processes while generating happy and loyal customers. This book will show readers how to use FMEA to anticipate and prevent problems, reduce costs, shorten product development times, and achieve safe and highly reliable products and processes.

CARL S. CARLSON is a consultant and instructor in the areas of FMEA, reliability program planning, and other reliability engineering disciplines. He also currently supports clients of ReliaSoft Corporation. He has thirty years' experience in reliability testing, engineering, and management positions, including manager of product reliability at General Motors. He co-chaired the cross-industry team that developed the commercial FMEA standard (SAE J1739, 2002 version) and was a past member of the Reliability and Maintainability Symposium (RAMS) Advisory Board. He holds a BS in mechanical engineering from the University of Michigan and is a Certified Reliability Engineer.

CARL S. CARLSON is a consultant and instructor in the areas of FMEA, reliability program planning, and other reliability engineering disciplines. He also currently supports clients of ReliaSoft Corporation. He has thirty years' experience in reliability testing, engineering, and management positions, including manager of product reliability at General Motors. He co-chaired the cross-industry team that developed the commercial FMEA standard (SAE J1739, 2002 version) and was a past member of the Reliability and Maintainability Symposium (RAMS) Advisory Board. He holds a BS in mechanical engineering from the University of Michigan and is a Certified Reliability Engineer.

Chapter 2

The Philosophy and Guiding Principles for Effective FMEAs

In matters of style, swim with the current; in matters of principle, stand like a rock.

—Thomas Jefferson

IN THIS CHAPTER

One of the keys to effective Failure Mode and Effects Analyses (FMEAs) is for the entire FMEA process to be driven by the correct philosophy, meaning that the approach is based on the vital few guiding principles that support achieving high reliability in today’s competitive environment. This chapter lays out the primary focus areas for doing timely FMEAs effectively. The remaining chapters in this book build on these guiding principles.

2.1 WHAT IS PHILOSOPHY AND WHY DOES IT MATTER TO FMEAs?

We are boxed in by the boundary conditions of our thinking.

—Albert Einstein

Philosophy is a theory or attitude that guides one’s behavior. FMEA is a tool that exists in the larger framework of quality and reliability processes. If one’s approach to achieving quality and reliability is sound, then it will properly guide the use of the FMEA tool. Basing one’s approach to FMEAs on wrong principles, such as fixing existing problems rather than anticipating and preventing them, or on incorrect objectives, such as “to fill out a form” or “to comply with a mandate,” will reap unsatisfactory results.

The guiding principles below originate from the overall philosophy of FMEA as communicated in the Introduction to this book. Again:

Through the synergy engendered by the right team of experts, and by implementing correct and proven methods and procedures, problems can be anticipated and prevented resulting in safe and trouble-free products and processes, with the inherent risk in any system or process reduced to a very low level.

2.2 GUIDING PRINCIPLES FOR EFFECTIVE FMEAs

Each of the following is an important guiding principle, applicable to any type of FMEA, which should direct the FMEA process and FMEA practitioners. The remainder of this book embraces these principles.

2.2.1 Having the Right Objectives

If you don’t know where you are going, you will wind up somewhere else.

—Yogi Berra

Focus on Problem Prevention

Preventing problems saves money and improves products. Fixing problems is necessary when they occur, but is substantially more expensive than problem prevention. There is a different mindset in an organization that focuses on problem prevention, and the tools and timing are different. FMEA is a key tool to prevent problems before designs reach testing or processes reach the plant floor, and to improve tests and controls to be sure problems do not reach consumers. The emphasis for this entire book is problem prevention.

Focus on Design and Process Improvements

In order to achieve safe and reliable product and process designs in a timely manner, it is essential for FMEAs to drive design and process improvements as the primary objective. Safe and trouble-free designs and stable, capable, and error-proof manufacturing processes must be the primary goal. FMEAs need to drive action strategies that improve designs and processes. Chapter 7 describes many action strategies that can be employed to improve designs and processes, and reduce risk to a very low level.

Leverage FMEAs to Improve Test Plans and Process Controls

Effective product testing and manufacturing process controls are essential elements of successful product development. Tests and process controls must accurately detect all possible failures and their causes based on the entire range of operating profiles and customers usages. FMEAs can and should improve test plans and process controls. Chapter 6 shows how FMEAs link to design verification and process controls.

Select FMEA Projects Based on Preliminary Risk Assessment

FMEAs take time and cost money. It is not possible to perform FMEAs on every subsystem and component. A company should use the FMEA tool for projects that present a threshold level of risk based on a preliminary risk assessment. Chapter 4, Section 4.2, explains how to select FMEA projects.

Keep It Simple

Some FMEA practitioners complicate FMEAs with extraneous and nonvalue information. Columns can be added to FMEAs that may seem like a good idea, but add time without corresponding value. Risk ranking scales can have too many ranking levels and complex criteria that lack clarity. Each and every worksheet column, scale, preparation task, and procedure step must pass this simple test: does it add sufficient value to justify the time that is expended? One of the overriding principles of effective FMEAs is to keep to the essential elements. This book intends to empower FMEA practitioners with knowledge about all aspects of FMEAs so they can make the right choices at each stage and keep the procedure as simple as possible.

2.2.2 Having the Right Resources

When every physical and mental resource is focused, one’s power to solve a problem multiplies tremendously.

—Norman Vincent Peale

FMEA Is a Team-Based Activity

To be successful, FMEAs need the right team of subject matter experts. Even the best engineers have blind spots and only a team composed of the right disciplines can provide the necessary input and discussion to ensure all concerns are surfaced and addressed. FMEAs should not be performed by one or two individuals, or with the wrong team composition. Chapter 5, Section 5.3.4, provides guidance in establishing the correct FMEA team and ensuring they are properly trained.

Fully Understand the Basics of FMEAs

There is no shortcut to understanding the definitions and concepts of FMEAs. Knowing the basics of FMEAs, such as key definitions and concepts, is essential for learning the proper application of FMEAs to achieve safe, reliable, and economical products and processes. FMEA teams need to be well trained on the fundamentals of FMEA and the correct procedures. Chapter 3 covers all of the key definitions, with many real-world examples.

Provide Skilled FMEA Facilitation and Unleash FMEA Team Creativity

The skill set needed to perform FMEAs is not the same as the skill set needed to facilitate FMEA projects. Good facilitation is crucial for attaining the best results from FMEA teams, shortening FMEA in-meeting time, and maximizing the contributions from subject matter experts. Chapter 10 outlines and explains the unique skills for facilitating successful FMEA projects.

Albert Einstein said, “I am enough of an artist to draw freely upon my imagination. Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world.” When he said that, he certainly did not mean knowledge is not important. What he meant is that creativity and imagination play significant roles in developing new technology, new products, and new solutions. Many high-risk problems require thinking “outside the box,” and the FMEA team can solve very difficult problems when a skilled facilitator energizes its power of creativity. Chapter 10 covers how to facilitate productive FMEA meetings, unleash creativity, and move the team through the FMEA process to excellent results in a timely manner.

Benefit from Real-World Lessons Learned

FMEA has been around for over 50 years and there have been many important lessons learned. Based on the knowledge from thousands of FMEAs and hundreds of companies, certain mistakes are seen to occur repeatedly. FMEA practitioners should not keep repeating these same mistakes. Chapter 9 reveals the most common FMEA mistakes and tells how to translate them into FMEA quality objectives so that results are uniformly exceptional. This chapter also describes an FMEA audit process based upon the FMEA quality objectives.

Another part of lessons learned is the field problems discovered after an FMEA analysis has been completed. No company has ever introduced products with no field problems or failures. An effective process must be in place to capture the test and field failures missed by FMEAs and provide these as input to future FMEA teams.

Management Plays a Key Role in Establishing and Supporting an Effective FMEA Process

Individual FMEA practitioners can do their very best to perform FMEAs correctly, but there are certain vital activities that are the proper role of management to implement an effective FMEA process. Without these management-supported steps, FMEAs can flounder and miss the mark. These include establishing the strategy, providing the resources, implementing reviews of high-risk issues, supplier management, FMEA quality audits, integrating FMEAs with other businesses process, and providing the right FMEA software. Chapter 11 outlines the best practices of successful companies in achieving uniformly great results with FMEAs and explains some of the common FMEA implementation mistakes and how to avoid them. Chapter 16 shows how to select the right FMEA software that optimizes FMEA team effectiveness.

Support the Natural Passion and Energy of Employees to Achieve Trouble-Free Products

FMEAs have had a reputation for being long, drawn out, and uninteresting. This does not have to be the case and it is hoped that this book will change that reputation where it exists. Every person in a company or organization wants to support safe and trouble-free designs and processes. By following the steps in this book, everyone involved with FMEAs can be part of a...

| Erscheint lt. Verlag | 11.4.2012 |

|---|---|

| Reihe/Serie | Quality and Reliability Engineering Series |

| Wiley Series in Quality and Reliability Engineering | Wiley Series in Quality and Reliability Engineering |

| Sprache | englisch |

| Themenwelt | Technik ► Elektrotechnik / Energietechnik |

| Technik ► Maschinenbau | |

| Wirtschaft ► Betriebswirtschaft / Management ► Unternehmensführung / Management | |

| Schlagworte | Electrical & Electronics Engineering • Elektrotechnik u. Elektronik • failure modes and effects analysis, FMEA, FMEA procedure, FMEA risk assessment, how to implement FMEA • FMEA • Industrial Engineering • Industrial Engineering / Quality Control • Industrielle Verfahrenstechnik • Qualität, Produktivität u. Zuverlässigkeit • Qualitätssicherung i. d. Industriellen Verfahrenstechnik • Qualität u. Zuverlässigkeit • Qualität, Produktivität u. Zuverlässigkeit • Qualitätssicherung i. d. Industriellen Verfahrenstechnik • Qualität u. Zuverlässigkeit • Quality & Reliability • Quality, Productivity & Reliability • Statistics • Statistik |

| ISBN-10 | 1-118-31258-9 / 1118312589 |

| ISBN-13 | 978-1-118-31258-2 / 9781118312582 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich