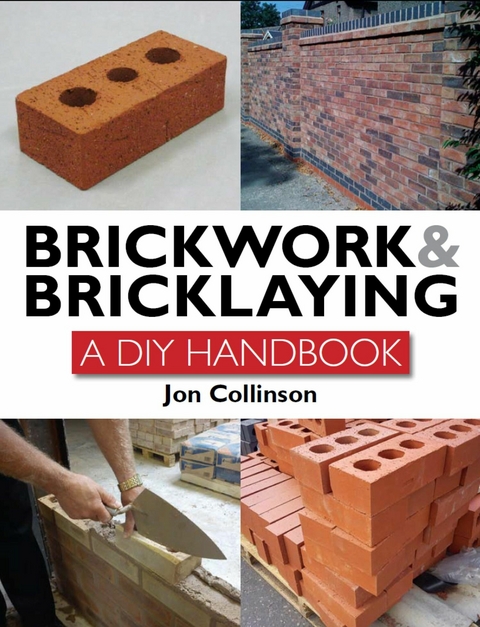

Brickwork and Bricklaying (eBook)

425 Seiten

Crowood (Verlag)

978-1-84797-579-9 (ISBN)

Brickwork and Bricklaying is written for those who are new to the craft of bricklaying, and those who are improving their skills. It provides an overview of the materials, processes, craft skills and related subjects to enable the reader to construct their own simple brickwork projects and undertake brickwork-related maintenance projects around the home.

Mortar is the ‘chemical glue’ and ‘gap-filling adhesive’ that holds masonry structures together. Its purpose is to even out any slight irregularities in brick shape and size and it has a direct influence on compressive strength, durability and resistance to rain penetration through brick walling. On this basis it is as fundamental to the construction of a wall as the bricks or blocks themselves.

In basic terms, mortar is a mixture of an aggregate (soft sand or builders’ sand), a binder (usually Ordinary Portland cement) and water. Additives such as plasticizers and pigments can be added in order to achieve a particular performance objective. Water is added to form a paste with the cement, which covers the surface area of every sand particle in the mix, binding the particles together to form a solid mass when the mortar hardens. The sand is not physically altered in any way, but is firmly set into the hardened, rock-like cement paste.

REQUIREMENTS

From a bricklayer’s point of view a mortar should be ‘fatty’ – in other words, it should handle well without being sticky, spread easily and set at the right pace to allow time to finish the joints in all weather conditions. If a mortar satisfies all these requirements it is said to have ‘workability’. Harsh mortars with low workability slow down the bricklaying process and reduce a bricklayer’s output. Picking up and spreading the mortar is more difficult, as is placing the cross-joints on the ends of bricks – harsh mortars tend to have poor adhesion and will fall away from the brick and/or trowel. Workability is much improved by the addition of plasticizers or lime to the mix. In achieving ‘workability’ a number of other factors must not be overlooked.

Retention of Plasticity

The length of time that mortar retains its plasticity is something of a trade-off. Plasticity should be retained long enough to allow the bricks to be laid, adjusted and a joint finish applied before the mortar dries out too much. This is more of a problem where very dry bricks are used, as they have a high suction rate. Alternatively, mortars that are excessively plasticized can be laid only to limited heights before the wall sinks and bed joints of the lower courses start to squeeze out.

Durability

The extent of a mortar’s durability (in other words, its resistance to weather, frost and chemical attack), as determined by the mix proportions, must be suitable for the purpose for which it is used. For example, a comparatively weak mix may be suitable for an internal block partition but the same mix would weather and deteriorate quite quickly if used on an exposed boundary wall.

Good Bond with Bricks

Strong mortar mixes with a high cement content have a greater proclivity to drying shrinkage, which results in the mortar joints effectively shrinking away from the bricks. The fine cracks between joint and brick undermine structural strength and allow rain to penetrate, with the potential for frost damage during winter months. Some bricks, such as concrete or sand/lime bricks, also display high rates of drying shrinkage and such problems are exacerbated if they are laid in harsh, strong mortars.

Adequacy of Compressive Strength

Mortars that are overly strong will respond to differential movement with cracks, which may be few in number but they will be large, and usually through the bricks or blocks themselves rather than in the mortar joints. Weaker mortars on the other hand are capable of accommodating small amounts of structural movement and any cracking will be hairline in nature and concentrated in the joints. In the event that remedial work is required, raking out and re-pointing joints is a much easier and quicker task than the wholesale chopping-out and replacing of cracked bricks.

MORTAR MIX DESIGN

It is not possible for one mortar mix to provide all the required characteristics to the maximum extent. For example, great strength can be achieved using a 3:1 sand and cement mortar but this is at the expense of poor workability, for one thing. For a given set of circumstances, then, the ideal mortar mix has the following characteristics:

- it provides an appropriate balance between good workability and plasticity retention for the bricklayer;

- a good bond with the bricks or blocks being laid;

- it allows joints to be compressed and sealed against the driving rain and wind;

- its appearance is complementary to that of the bricks;

- it is sufficiently durable for its location or use and of adequate strength, but slightly less strong (and certainly no stronger) than the bricks or blocks being bedded. (This makes the choice of bricks a key determining factor in terms of mortar mix design.)

The final strength of the mortar is determined by the strength of the brick or block to be bedded in it. The mortar strength should roughly match that of the brick or block but it should not be greater, so that any cracking from movement occurs in the joints and not in the bricks, thus making remedial repairs easier.

Typically, these criteria can be most easily met by using a mix containing cement, hydraulic lime and sand, in proportions appropriate for its use.

Ordinary Portland Cement

Ordinary Portland cement is the most commonly used for bricklaying mortar. In order to ensure consistency of mortar colour, cement should be sourced from just one place for each building project.

Cement–Lime–Sand Mortar

Often referred to as ‘compo’, this mix contains a proportion of hydraulic lime for a number of reasons. Lime contributes little in terms of strength but it does act as a plasticizer to make the mortar more workable. Lime also has good water-retaining properties, which means that the setting time of the mortar is slowed, with the mortar staying workable and keeping its plasticity for longer. The presence of lime renders the set mortar somewhat more flexible than sand–cement mortar, meaning that differential structural movement is more easily accommodated. The addition of lime also enhances the aesthetics of mortar by giving it a more creamy appearance.

Hydraulic Lime

There are two types of lime: ‘hydraulic’ lime, which sets under water, and ‘non-hydraulic’ lime, which needs air in which to set. The construction industry commonly uses non-hydraulic lime, which is manufactured by heating pure limestone in a kiln to 1066 degrees centigrade. The resultant ‘quicklime’ is then mixed with water (in a process known as ‘slaking’) to make lime putty, or with less water to produce hydrated lime in the form of a fine, white powder that is delivered to site in 25-kg bags. Since lime is less dense than cement, a 25-kg bag of lime is significantly larger than a bag of cement of the same weight.

Being hydraulic, bags of lime must be protected from damp before use. Preferably, bags should be stored clear of the ground on a wooden pallet in a well-ventilated, rain-proof shed. Bags of lime should be stacked flat, not more than five bags high. If stacking outside cannot be avoided, bags should be raised off the ground and adequately sheeted with polythene, ensuring a good overlap. It is vitally important to keep the bags dry.

Fig. 18 Size comparison of 25-kg bags of Ordinary Portland cement and hydraulic lime.

Fig. 19 Hydraulic lime.

Before the widespread use of cement, mortar used in bricklaying was referred to as ‘coarse stuff’, a 3:1 ratio (aggregate to lime) mortar mix using non-hydraulic lime putty, well-graded sharp sand and soft sand. It is still available today from specialist suppliers and is suitable for repairs to historic buildings, blocklaying, bricklaying, stonemasonry, the re-pointing of brickwork, the repair and plastering of internal walls (as a backing or finishing coat), and the repair or rendering of external walls.

SAND

Sands and aggregates are natural products used in the production of mortar and concrete. They are usually excavated from locations where ancient river and sea beds were re-formed during the early periods of the earth’s structure. The term ‘aggregate’ is a generic one used to describe gravels, stones and sharp sand, which are mixed with cement and water to make concrete

Fig. 20 Soft red sand.

Fig. 21 Soft yellow sand.

Sand

In order to ensure consistency of mortar colour, always obtain sand from one source only for each building project.

The terms ‘fine aggregate’, ‘concreting sand’ or ‘sharp sand’ describe the natural sand, crushed stone or similar that passes through a 5mm sieve but tends to be coarser and not as well graded as the sands used in mortars. It is often referred to as ‘fine aggregate’ to distinguish it from soft sand. Being coarser than soft sand, it is not used for mortars as it produces an unworkable mix and causes difficulties with achieving a good finish when jointing. The sand used for mortar is referred to as ‘soft sand’ (or sometimes ‘builders’ sand’), as distinct from the fine aggregate (also known as ‘sharp sand’) used in the mixing of concrete.

Soft sand should be...

| Erscheint lt. Verlag | 30.6.2013 |

|---|---|

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Heimwerken / Do it yourself |

| Recht / Steuern ► Öffentliches Recht | |

| Technik ► Bauwesen | |

| Weitere Fachgebiete ► Handwerk | |

| ISBN-10 | 1-84797-579-8 / 1847975798 |

| ISBN-13 | 978-1-84797-579-9 / 9781847975799 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich