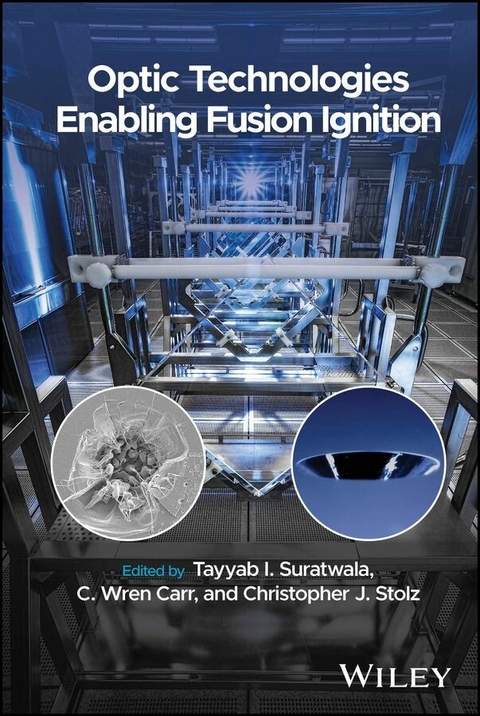

Optic Technologies Enabling Fusion Ignition (eBook)

1107 Seiten

Wiley (Verlag)

978-1-394-26825-2 (ISBN)

A powerful and up-to-date desk reference for advancements in optic technologies for high energy lasers

In Optic Technologies Enabling Fusion Ignition, a team of veteran optics and laser specialists deliver an expert summary of optic manufacturing technologies, laser-induced optic damage reduction technologies, and optic repair & recycle technologies. The authors explore the fundamental scientific phenomena and how they have driven the development of optic technologies as well as the process of transitioning from scientific discovery to large-scale production.

The book combines examinations of improving overall optic performance, optic survivability, and laser performance. It also covers novel bulk material developments, yield processing improvement methods, novel metrologies, and advancements in increasing laser-induced damage resistance.

Readers will also find:

- A thorough introduction to the details of optics recycle loop technologies, including the refurbishment and repair of laser-induced damaged optics

- Comprehensive explorations of advancements in optical fabrication and post-processing reducing laser damaging surface precursors

- Practical discussions of the fundamental physics of laser-matter interactions related to laser-induced damage

- Complete treatments of laser-induced damage data management, the use of online shadow blockers, and novel optics metrologies

Ideal for optical and laser scientists, engineers, and fabricators of optical materials and components, Optic Technologies Enabling Fusion Ignition is also a valuable resource for graduate students interested in optics, as well as high-energy and high-power laser research.

Tayyab I. Suratwala, PhD, is the Program Director for Optics and Materials Science & Technology (OMST) in the NIF & Photon Science Directorate at Lawrence Livermore National Laboratory (LLNL). He has 28 years of experience in optical fabrication and materials processing.

C. Wren Carr, PhD, is a Group Leader for Science & Technology for OMST at LLNL. He has 25 years of experience in the field of laser-induced damage in optical materials.

Christopher J. Stolz is the former Group Leader for Optics Supply for OMST at LLNL. He has 36 years of experience in high fluence multilayer optical coatings and optical fabrication.

A powerful and up-to-date desk reference for advancements in optic technologies for high energy lasers In Optic Technologies Enabling Fusion Ignition, a team of veteran optics and laser specialists deliver an expert summary of optic manufacturing technologies, laser-induced optic damage reduction technologies, and optic repair & recycle technologies. The authors explore the fundamental scientific phenomena and how they have driven the development of optic technologies as well as the process of transitioning from scientific discovery to large-scale production. The book combines examinations of improving overall optic performance, optic survivability, and laser performance. It also covers novel bulk material developments, yield processing improvement methods, novel metrologies, and advancements in increasing laser-induced damage resistance. Readers will also find: A thorough introduction to the details of optics recycle loop technologies, including the refurbishment and repair of laser-induced damaged opticsComprehensive explorations of advancements in optical fabrication and post-processing reducing laser damaging surface precursorsPractical discussions of the fundamental physics of laser-matter interactions related to laser-induced damageComplete treatments of laser-induced damage data management, the use of online shadow blockers, and novel optics metrologies Ideal for optical and laser scientists, engineers, and fabricators of optical materials and components, Optic Technologies Enabling Fusion Ignition is also a valuable resource for graduate students interested in optics, as well as high-energy and high-power laser research.

List of Figures

| Figure 1.3 | (a) Schematic of the National Ignition Facility (NIF) laser; (b) configuration of the NIF large optics in a single NIF beamline; (c) photos of the various types of NIF large optics. |

| Figure 1.4 | NIF vendor partners that made the bulk material (blanks) or fabricated (finishing and coating) the large NIF build and operational optics. |

| Figure 1.5 | Timeline of important optic technologies developed since the mid-1990s for NIF. |

| Figure 1.8 | Schematic illustrating the optics recycle loop strategy used on NIF. |

| Figure 1.12 | Evolution of the distribution of the high-fluence beam shots on NIF for various fiscal years. |

| Figure 2.3 | Schematic representation of the optics and environments on NIF. |

| Figure 2.10 | Beam dumps installed to capture 3ω ghost reflections from the final optics to prevent laser-induced damage to the final transport mirror. |

| Figure 2.12 | Photo and cross-sectional schematic of the plasma electrode Pockels cell (PEPC). |

| Figure 2.13 | Two frequency-conversion crystals are used to convert the 1ω laser to a 3ω laser with modest residual 1ω and 2ω light also transmitted into the Target Chamber. |

| Figure 2.14 | CPPs are used on NIF to create an enlarged and uniform spot size on target. |

| Figure 2.16 | Installation of two DDS cassettes, each containing five DDS optics per NIF beamline. |

| Figure 2.18 | Pulse-compression gratings are used on the ARC diagnostic laser to create a high-energy ultra-short pulse to backlight targets during compression. |

| Figure 2.19 | Pulse-compression gratings are etched into a thick silica layer on top of a multilayer dielectric mirror. |

| Figure 2.20 | The exposure laser beams in the holographic exposure apparatus illuminate the 1100-mm aperture collimation lens to expose the large diffractive gratings. |

| Figure 2.21 | Large reactive ion beam system is capable of etching submicron features into substrates as large as... |

| Erscheint lt. Verlag | 10.7.2025 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie |

| Technik ► Maschinenbau | |

| Schlagworte | Laser Performance • optical fabrication • optic laser-induced damage reduction technologies • Optic manufacturing technologies • optic recycle loop technologies • optics manufacturing • optics performance • optics recycling • optic survivability |

| ISBN-10 | 1-394-26825-4 / 1394268254 |

| ISBN-13 | 978-1-394-26825-2 / 9781394268252 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich