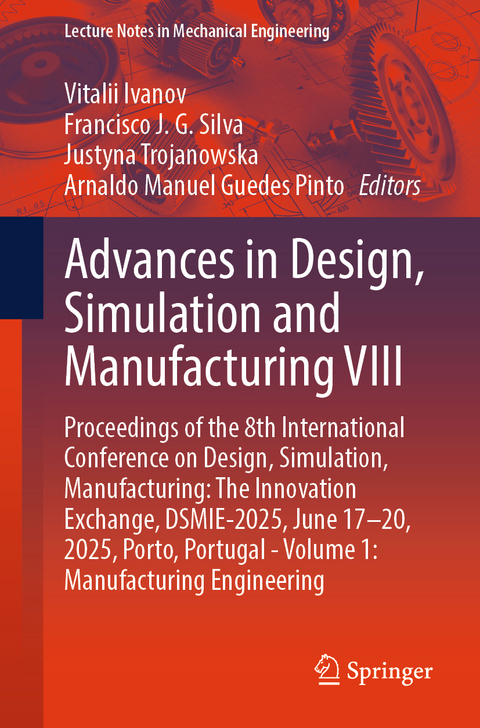

Advances in Design, Simulation and Manufacturing VIII

Springer International Publishing (Verlag)

978-3-031-95210-4 (ISBN)

This book reports on advances in manufacturing, with a special emphasis on smart and sustainable systems and strategies. It covers advances in additive manufacturing, multi-pin ultrasonic peening, shot peening, and hot isostatic pressing; topics in stamping, injection moulding, assembly processes; strategies for improving the durability and service life of engineering products and machines; advances in machining processes, particularly milling and vibro-abrasive methods; and industrial robotics. Chapters report on theoretical research, mathematical modeling, and experimental studies concerning the design engineering of robots and machine tools, alike. They also discuss key aspects of quality assurance of products for milling and moulding processes, as well as multiaxis machining in flexible fixtures. Based on the 8th International Conference on Design, Simulation, Manufacturing: The Innovation Exchange (DSMIE-2025), held on June 17-20, 2025, in Porto, Portugal, this first volume of a 4-volume set provides academics and professionals with extensive information on technologies, trends, challenges, and practice-oriented experience in all the above-mentioned areas.

Advancements in 3D Printing: Materials, Technologies, and Industrial Applications.- Theoretical Prerequisites for Increasing the Durability and Service Life of Working Bodies of Tillage Machines.- Development of a Novel Assembling Process for Small Automotive Mechanical Devices.- An Experimental and Multi-Objective Optimization Study of FFF-Printed PETG Parts Under Compressive Loads.

| Erscheinungsdatum | 12.06.2025 |

|---|---|

| Reihe/Serie | Lecture Notes in Mechanical Engineering |

| Zusatzinfo | XVI, 360 p. 174 illus., 142 illus. in color. |

| Verlagsort | Cham |

| Sprache | englisch |

| Maße | 155 x 235 mm |

| Themenwelt | Technik ► Elektrotechnik / Energietechnik |

| Technik ► Maschinenbau | |

| Schlagworte | 3D Printing • automated control systems • Automated Warehouse • dimensional accuracy • Enhancing Product Quality • Flexible Fixtures • Grinding System • Improving Wear Resistance • Intelligent Manufacturing Systems • Mathematical Modeling in Manufacturing • Minimum Quantity Lubrication • Multi-Pin Ultrasonic Peening • Precision Manufacturing • Safe Industrial Robots • smart manufacturing • Sustainable Engineering Design • sustainable machining • Sustainable Supply Chain • Vibration Resistance • Vibro-Abrasive Polishing |

| ISBN-10 | 3-031-95210-3 / 3031952103 |

| ISBN-13 | 978-3-031-95210-4 / 9783031952104 |

| Zustand | Neuware |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich