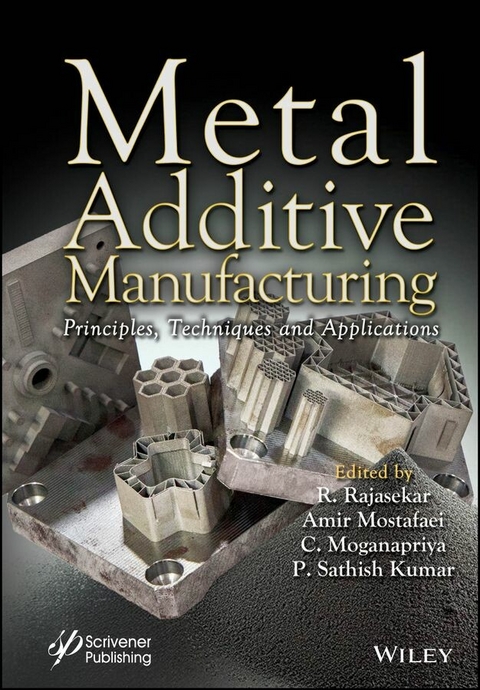

Metal Additive Manufacturing (eBook)

1039 Seiten

Wiley-Scrivener (Verlag)

978-1-394-28763-5 (ISBN)

This informative and practical guide to metal additive manufacturing explores techniques, applications, and future advancements.

Metal additive manufacturing stands as a revolutionary technology and a rapid prototype for engineering applications. In the realm of advanced manufacturing, it has long been a driving force in the development of AM metal technology. Moreover, it is now paving the way for high-value manufacturing components blended with sophisticated materials.

The book examines this rapidly evolving field and elucidates the foundations of metal additive manufacturing, including its various technologies, material design principles, and extrusion processes. Real-world applications are showcased, with examples from the aerospace, automotive, and healthcare industries, demonstrating the practical impact of metal AM. Chapters thoroughly discuss the evolution of manufacturing techniques, classifications of AM technologies, and the critical role of characterization in ensuring quality. The book emphasizes the importance of metal AM processes and their transformative potential for modern manufacturing. It concludes with coverage of future trends and advancements in additive manufacturing.

Audience

The book equips manufacturing and production engineers, researchers, and professionals with metal AM knowledge for the production of high-value components, driving innovation and efficiency in manufacturing.

R. Rajasekar, PhD, is a professor and dean of research and development in the Mechanical Engineering Department at Kongu Engineering College, Tamil Nadu, India. His research focuses on polymers, solar energy, nanocomposites, layer-by-layer assembly, thin films, anti-reflection coating materials, machining, welding, etc. He holds two patents.

Amir Mostafaei, PhD, is an assistant professor in the Department of Mechanical, Materials, and Aerospace Engineering at the Illinois Institute of Technology, Chicago. He has published more than 65 research papers in international/national journals and six book chapters.

C. Moganapriya, PhD, is an associate professor in the School of Mechanical Engineering at Vellore Institute of Technology, Chennai, Tamil Nadu, India. Her research focuses on material technology, manufacturing, cryogenic treatments, process optimization, and solar cells. She has published more than 40 research articles and 37 book chapters.

P. Sathish Kumar, PhD, is a research scientist at King Mongkut's University of Technology North Bangkok, Thailand. His research interests include polymer nanocomposites/composites, polymer blends and biomaterials, mechanical behavior of materials, thin film coating, etc.

This informative and practical guide to metal additive manufacturing explores techniques, applications, and future advancements. Metal additive manufacturing stands as a revolutionary technology and a rapid prototype for engineering applications. In the realm of advanced manufacturing, it has long been a driving force in the development of AM metal technology. Moreover, it is now paving the way for high-value manufacturing components blended with sophisticated materials. The book examines this rapidly evolving field and elucidates the foundations of metal additive manufacturing, including its various technologies, material design principles, and extrusion processes. Real-world applications are showcased, with examples from the aerospace, automotive, and healthcare industries, demonstrating the practical impact of metal AM. Chapters thoroughly discuss the evolution of manufacturing techniques, classifications of AM technologies, and the critical role of characterization in ensuring quality. The book emphasizes the importance of metal AM processes and their transformative potential for modern manufacturing. It concludes with coverage of future trends and advancements in additive manufacturing. Audience The book equips manufacturing and production engineers, researchers, and professionals with metal AM knowledge for the production of high-value components, driving innovation and efficiency in manufacturing.

1

Technologies for Additive Manufacturing of Metals and Their Classification

Bhuvanesh Kumar M.1*, Justus Panicker C. T.2 and Arivazhagan D.1

1Department of Mechanical Engineering, Kongu Engineering College, Erode, India

2Department of Production Engineering, National Institute of Technology, Tiruchirappalli, India

Abstract

Additive manufacturing is a process of depositing materials in a layer-by-layer fashion, which eliminates the complexity associated with design, manufacturing, and post processing activities. Over the past years, the technology for Metal Additive Manufacturing Process (MAMP) has achieved significant advancements and developments in understanding the parameters that influence the quality of manufactured parts. The MAMP uses different forms of input materials and varying deposition rates, producing different characteristics of printed parts. Despite the wide range of sources available to gain deeper knowledge about the relationship between process parameters and resulting part characteristics, a comprehensive understanding requires a basic knowledge of the field. This chapter provides a concise classification of various MAMPs available, along with their principles of operation, operating parameters, resulting part quality, and associated applications.

Keywords: Metal additive manufacturing process (MAMP), directed energy deposition (DED), powder bed fusion (PBF), selective laser melting (SLM), wire arc additive manufacturing (WAAM), cold metal transfer (CMT)

1.1 Introduction

Additive manufacturing is a transformative process that constructs objects layer by layer from a digital model. It enables the production of intricate designs and complex structures that traditional manufacturing methods struggle to achieve. With benefits like design freedom, reduced material waste, and faster production, additive manufacturing is revolutionizing the aerospace, automotive, and healthcare industries. It has the potential to streamline supply chains by enabling on-demand and decentralized production. While conventional manufacturing processes, like computer numerical control, are still better suited for mass production of less complex parts, Metal Additive Manufacturing Processes (MAMP) are growing rapidly due to their ability to create complex parts at ease and a higher level of control. Several technologies exist for metal additive manufacturing, each with unique characteristics and capabilities. The classification of metal additive manufacturing technologies is based on the specific process employed, the energy source utilized, and the way the metal material is deposited and solidified. Standard techniques include Powder Bed Fusion (PBF) methods like Selective Laser Melting (SLM) and Electron Beam Melting (EBM), as well as Directed Energy Deposition (DED) and Binder Jetting. Ongoing advancements in speed, precision, and material compatibility continue to expand the applications and potential of metal additive manufacturing.

One of the most remarkable advantages of metal additive manufacturing lies in its ability to construct highly complex geometries that traditional manufacturing methods struggle to achieve. It is possible to design intricate lattice structures, incorporate internal channels, and optimize designs by incrementally building layers, enhancing performance while minimizing weight. Metal additive manufacturing also boasts significant benefits such as reduced material waste, shorter production lead times, and improved design flexibility. By utilizing only the necessary amount of material and eliminating the need for multiple tooling setups, it substantially curtails material costs. Additionally, the technology enables swift prototyping and on-demand production, facilitating accelerated product development cycles and customization. However, it is important to acknowledge the challenges inherent in metal additive manufacturing. The process can be time-consuming, especially for large parts, and the quality of the final output can be influenced by factors such as powder quality, process parameters, and post-processing requirements. Furthermore, the initial investment cost for metal additive manufacturing equipment is substantial, and skilled operators are essential for its operation.

Despite these challenges, metal additive manufacturing has gained remarkable traction in diverse industries, including aerospace, automotive, healthcare, and tooling. Its capacity to fabricate lightweight, intricate, and tailor-made metal components with elevated performance characteristics positions it as a transformative manufacturing technology for future applications. As research and development continue to push the boundaries of metal 3D printing, these technologies will play a vital role in shaping the future of manufacturing and unlocking innovative applications across various sectors.

1.2 Metal Additive Manufacturing Process (MAMP)

The metal additive manufacturing process consists of sequential step common to all other additive manufacturing processes:

- Digital Design: The process begins with the creation of a digital 3D model of the desired metal object using Computer-Aided Design (CAD) software. This digital model serves as the blueprint for the additive manufacturing process.

- Slicing: The digital model is sliced into thin cross-sectional layers using specialized software. Each layer represents a specific height or thickness that the metal object will be built upon during the additive manufacturing process. If material has overhanging structures at the risk of collapsing and difficult to print, it is recommended to add support structures to the material before slicing.

- Material Preparation: The appropriate metal material and its form for the specific additive manufacturing technology is selected. This can include metal powders, metal filaments, or other forms of metal feedstock. The metal material may be pre-treated or prepared to optimize its properties for the printing process.

- Printing Process: The metal additive manufacturing machine, such as a 3D printer, receives the sliced digital model and starts the printing process. The working nature of the printing would depend on the technology being employed. For example, consider the two commonly used techniques in metal additive manufacturing.

- Powder Bed Fusion (PBF): In PBF, a thin layer of metal powder is evenly spread across a build platform. A high-energy source, such as a laser or electron beam, selectively scans the surface of the powder bed according to the specific layer’s design. The heat from the energy source melts and fuses the metal particles together, solidifying the layer. The build platform then moves down by one layer thickness, and the process is repeated for each subsequent layer until the entire object is complete [1].

- Directed Energy Deposition (DED): In DED, a focused energy source, typically a laser or electron beam, is used to melt a metal wire or powder as it is precisely deposited onto a substrate or previous layers. The energy source melts the material, which bonds with the substrate or previous layers, building up the object layer by layer.

- Cooling and Solidification: As each layer is deposited and fused, it cools and solidifies to form a solid part. Cooling can occur naturally or may be aided by cooling systems within the additive manufacturing machine. Proper cooling and solidification are essential to ensuring the structural integrity and dimensional accuracy of the final metal object.

- Post-Processing: Once the metal object is fully printed, it may undergo post-processing steps to improve its properties or aesthetics. Post-processing can include removing support structures if they were used during printing, heat treatment to enhance material properties, machining or surface finishing for desired surface quality, and any other required treatments based on the specific application requirements. The complete steps of MAMP are shown in Figure 1.1.

Figure 1.1 Metal additive manufacturing process [2].

1.3 Classification of MAMP Based on Technologies

The primary principle behind most metal additive manufacturing processes is to have a source of supply of the metal feedstock, which is then completed or partially melted and deposited on a build platform to obtain the required geometry. The variations among these processes can be understood by considering the type of metal feedstock, which can be wire, powder, solid, or liquid, and the method used to convert this raw material to the final shape. Figure 1.2 outlines the techniques of metal additive manufacturing [3].

The metal printing technique can be of liquid-based, where liquid metal droplets are deposited over each other to print the material [4]; solid-based, where solid sheets of metal, tailored to meet the required layer specification, are fused together by an external source [5]; or wire-based, where the raw material is in the form of a wire that is selectively melted and deposited over the build substrate to obtain the required geometry [6]. The technique can also be powder-based, where powder is selectively fused at a required place by using a particular source that creates ample adhesion between the powders [7].

1.4 Liquid-Based MAMP: Liquid Metal 3D Printing

The primary principle of liquid-based metal printing is that the raw material in the form of a wire is brought into a ceramic nozzle, which acts as a heater where the filler wire is melted to form a melt pool. The nozzle is surrounded by an...

| Erscheint lt. Verlag | 27.2.2025 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie |

| Technik ► Maschinenbau | |

| Schlagworte | 4D printing • classification • Direct Energy Deposition • Evolution • Intermetallic Components • manufacturing techniques • Material Design • Material Extrusion • Material Jetting • mechanical behavior • Mechanics • Metal Additive Manufacturing • Powder High-Speed Collision • Supply Chain Management |

| ISBN-10 | 1-394-28763-1 / 1394287631 |

| ISBN-13 | 978-1-394-28763-5 / 9781394287635 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich