Fundamentals of Chemical Reactor Engineering (eBook)

John Wiley & Sons (Verlag)

978-1-119-75591-3 (ISBN)

A comprehensive introduction to chemical reactor engineering from an industrial perspective

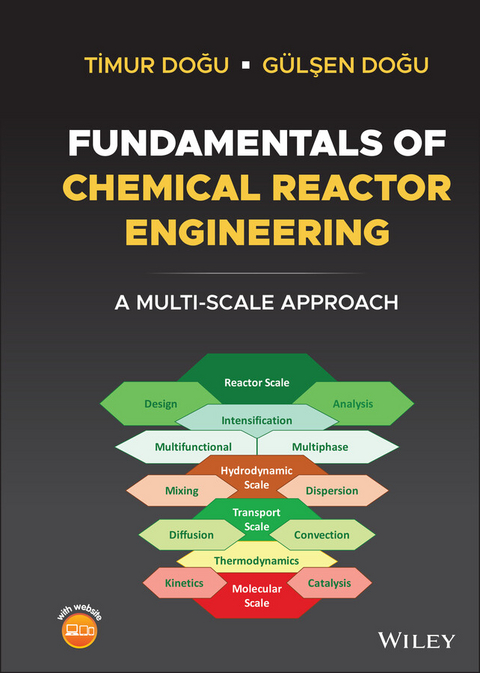

In Fundamentals of Chemical Reactor Engineering: A Multi-Scale Approach, a distinguished team of academics delivers a thorough introduction to foundational concepts in chemical reactor engineering. It offers readers the tools they need to develop a firm grasp of the kinetics and thermodynamics of reactions, hydrodynamics, transport processes, and heat and mass transfer resistances in a chemical reactor.

This textbook describes the interaction of reacting molecules on the molecular scale and uses real-world examples to illustrate the principles of chemical reactor analysis and heterogeneous catalysis at every scale. It includes a strong focus on new approaches to process intensification, the modeling of multifunctional reactors, structured reactor types, and the importance of hydrodynamics and transport processes in a chemical reactor.

With end-of-chapter problem sets and multiple open-ended case studies to promote critical thinking, this book also offers supplementary online materials and an included instructor's manual. Readers will also find:

- A thorough introduction to the rate concept and species conservation equations in reactors, including chemical and flow reactors and the stoichiometric relations between reacting species

- A comprehensive exploration of reversible reactions and chemical equilibrium, including the thermodynamics of chemical reactions and different forms of the equilibrium constant

- Practical discussions of chemical kinetics and analysis of batch reactors, including batch reactor data analysis

- In-depth examinations of ideal flow reactors, CSTR, and plug flow reactor models

Ideal for undergraduate and graduate chemical engineering students studying chemical reactor engineering, chemical engineering kinetics, heterogeneous catalysis, and reactor design, Fundamentals of Chemical Reactor Engineering is also an indispensable resource for professionals and students in food, environmental, and materials engineering.

Timur Dog?u, PhD, is a Professor at the Middle East Technical University. He received his doctorate from the University of California at Davis. His research is focused on reaction engineering, heterogeneous catalysis, environmental catalysis, synthesis of nanostructured mesoporous materials, transport phenomena effects on reaction rates, and process intensification.

Güls¸en Dog?u, PhD, is a Professor at Gazi University. She received her doctorate from the University of California at Davis. Her research focuses on environmentally clean processes, diffusion and reaction in porous media, catalyst development and alternative fuels.

FUNDAMENTALS OF CHEMICAL REACTOR ENGINEERING A comprehensive introduction to chemical reactor engineering from an industrial perspective In Fundamentals of Chemical Reactor Engineering: A Multi-Scale Approach, a distinguished team of academics delivers a thorough introduction to foundational concepts in chemical reactor engineering. It offers readers the tools they need to develop a firm grasp of the kinetics and thermodynamics of reactions, hydrodynamics, transport processes, and heat and mass transfer resistances in a chemical reactor. This textbook describes the interaction of reacting molecules on the molecular scale and uses real-world examples to illustrate the principles of chemical reactor analysis and heterogeneous catalysis at every scale. It includes a strong focus on new approaches to process intensification, the modeling of multifunctional reactors, structured reactor types, and the importance of hydrodynamics and transport processes in a chemical reactor. With end-of-chapter problem sets and multiple open-ended case studies to promote critical thinking, this book also offers supplementary online materials and an included instructor s manual. Readers will also find: A thorough introduction to the rate concept and species conservation equations in reactors, including chemical and flow reactors and the stoichiometric relations between reacting species A comprehensive exploration of reversible reactions and chemical equilibrium, including the thermodynamics of chemical reactions and different forms of the equilibrium constant Practical discussions of chemical kinetics and analysis of batch reactors, including batch reactor data analysis In-depth examinations of ideal flow reactors, CSTR, and plug flow reactor models Ideal for undergraduate and graduate chemical engineering students studying chemical reactor engineering, chemical engineering kinetics, heterogeneous catalysis, and reactor design, Fundamentals of Chemical Reactor Engineering is also an indispensable resource for professionals and students in food, environmental, and materials engineering.

Timur Dogvu, PhD, is a Professor at the Middle East Technical University. He received his doctorate from the University of California at Davis. His research is focused on reaction engineering, heterogeneous catalysis, environmental catalysis, synthesis of nanostructured mesoporous materials, transport phenomena effects on reaction rates, and process intensification. Güls¸en Dogvu, PhD, is a Professor at Gazi University. She received her doctorate from the University of California at Davis. Her research focuses on environmentally clean processes, diffusion and reaction in porous media, catalyst development and alternative fuels.

List of Symbols

| a | Pore radius | m |

| ab | Bubble area per unit liquid volume in a slurry | m2/m3 |

| ac | Activity factor |

| ae | External area of the catalyst pellet per unit volume in a slurry | m−1 |

| ai | The activity of species i |

| amem | Membrane surface area per reactor volume | m2/m3 |

| Ac | The cross‐sectional area of the reactor | m2 |

| Ae | External surface area of catalyst pellet | m2 |

| Ah | Heat transfer area | m2 |

| b | Half of the cell size in a monolith | m |

| B | Parameter defined by Eq. (8.39) |

| Bi h | Biot number for heat transfer (Eq. (10.79)) |

| Bi m | Biot number for mass transfer (Eq. (10.42)) |

| Specific heat of the mixture | J/kg K |

| C | Total concentration | mol/m3 |

| Cd | Darcy coefficient |

| Ci | The concentration of species i in the reactor | mol/m3 |

| The concentration of species i in the macro‐ and micro‐porous regions | mol/m3 |

| Cib | Bubble phase concentration of species i in a fluidized bed | mol/m3 |

| Cid | Emulsion (dense) phase concentration of i in a fluidized bed | mol/m3 |

| The concentration of species i at equilibrium |

| Cp | Molar heat capacity | J/mol K |

| db | Bubble diameter | m |

| dp | Pellet diameter | m |

| dt | Tube diameter | m |

| Da | Damköhler number (Eq. (10.44)) |

| Da , Di | Effective macro‐ and micro‐pore diffusivity | m2/s |

| DAB | Molecular diffusion coefficient of A in B | m2/s |

| De | Effective diffusion coefficient | m2/s |

| Knudsen diffusion coefficient of species i (Eq. (12.7)) | m2/s |

| Ds | Surface diffusion coefficient | m2/s |

| DT | Composite diffusivity (Eq. (12.21)) | m2/s |

| Composite diffusivity in the macro‐ and micro‐pore regions | m2/s |

| Dz | Axial dispersion coefficient | m2/s |

| e | Energy flux | J/m2 s |

| Ea | The activation energy of the reaction | J/mol |

| Observed activation energy | J/mol |

| fi | Fugacity of species i |

| Fi | Molar flow rate of species i | mol/s |

| FT | Total molar flow rate | mol/s |

| G | Gibbs free energy | J/mol |

| The mean value of the molar flow rate of the vapor stream in a distillation column | mol/s |

| GN | Molar flow rate of vapor stream leaving stage N in a distillation column | mol/s |

| h | Heat transfer coefficient | J/m2 s K |

| Hi | Enthalpy of species i | J |

| JD | J factor for mass transfer (Eq. (9.24)) |

| Ji | Diffusion flux of species i | mol/m2 s |

| k | Reaction rate constant for an nth‐order reaction | (mol/m3)(1−n)/s |

| kc | Mass transfer coefficient on catalyst surface in a slurry | m/s |

| kd | Deactivation rate constant | s−1 |

| kf | Forward reaction rate constant of (nth‐order reaction) | (mol/m3)(1−n)/s |

| kb | Backward reaction rate constant (nth‐order reaction) | (mol/m3)(1−n)/s |

| kg | Gas‐side mass transfer coefficient in a slurry | m/s |

| kl | Liquid side mass transfer coefficient in a slurry | m/s |

| km | Mass transfer coefficient | m/s |

| kobs | Observed rate constant (first‐order reaction) | s−1 |

| ko | Frequency factor in the Arrhenius equation |

| kw | Reaction rate constant based on catalyst mass |

| Ki | Adsorption equilibrium constant of species i |

| KC | The equilibrium constant in terms of concentrations |

| Kf | The equilibrium constant in terms of fugacities |

| KH | Henry's constant |

| Kl | Overall mass transfer coefficient | m/s |

| KP | The equilibrium constant in terms of partial pressures |

| Ky | The equilibrium constant in terms of mole fractions |

| L | Length of the reactor | m |

| Ls | Half thickness of a slab |

| Mean value of molar liquid flow rate in a distillation column | mol/s |

| LN | Liquid flow rate leaving stage N in a distillation column | mol/s |

| mn | The nth moment (Eq. (8.57)) |

| Mi | The molecular weight of species i | kg/mol |

| n | Unit normal vector |

| ni | Number of moles of i | mol |

| ni, ads | Adsorbed concentration of species i per unit mass of the catalyst | mol/kg |

| P | Pressure | Pa, atm |

| Pc | Critical pressure | Pa, atm |

| Ped | Peclet number in terms of tube diameter (8.46) |

| Pez | Axial Peclet number (Eq. (8.36)) |

| q | Heat transfer rate | J/s |

| qG | Heat generation rate | J/s |

| qR | Heat removal rate | J/s |

| Q | Volumetric flow rate | m3/s |

| r | Radial direction |

| rc | Core radius for unreacted‐core model | m |

| rcy | The radius of the cylindrical catalyst pellet | m |

| rg | Microporous particle/micro‐grain radius | m |

| ri | The radial direction in the microporous particles |

| ro | The radius of the tubular reactor | m |

| Erscheint lt. Verlag | 7.10.2021 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie ► Technische Chemie |

| Technik | |

| Schlagworte | catalysis • Catalysis & Chemical Reaction Engineering • chemical engineering • Chemie • Chemischer Reaktor • Chemische Verfahrenstechnik • Chemistry • Industrial Chemistry • Katalyse • Katalyse u. Chemische Reaktionstechnik • multi-scale, chemical reactor engineering, chemical engineering kinetics, heterogeneous catalysis, reactor design, biochemical reactions, food engineering, environmental engineering, materials engineering, process intensification, modeling, multifunctional reactors, structured reactor types, hydrodynamics, transport processes, heat and mass transfer • Technische u. Industrielle Chemie |

| ISBN-10 | 1-119-75591-3 / 1119755913 |

| ISBN-13 | 978-1-119-75591-3 / 9781119755913 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich