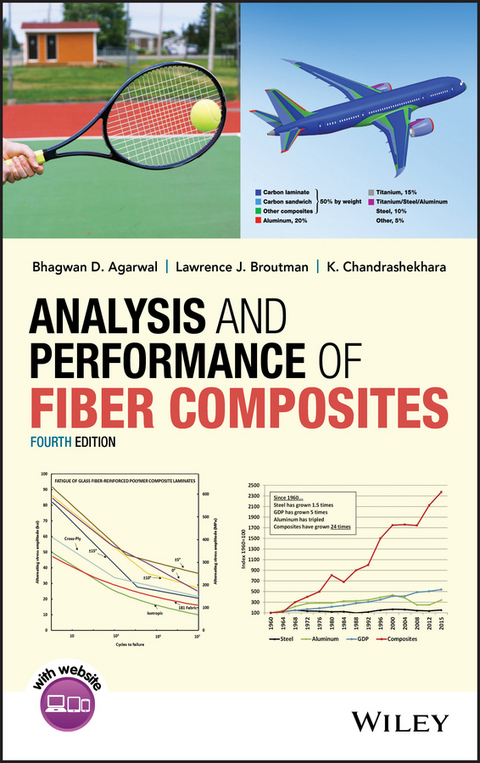

Analysis and Performance of Fiber Composites (eBook)

John Wiley & Sons (Verlag)

978-1-119-38997-2 (ISBN)

Updated and expanded coverage of the latest trends and developments in fiber composite materials, processes, and applications

Analysis and Performance of Fiber Composites, Fourth Edition features updated and expanded coverage of all technical aspects of fiber composites, including the latest trends and developments in materials, manufacturing processes, and materials applications, as well as the latest experimental characterization methods.

Fiber reinforced composite materials have become a fundamental part of modern product manufacturing. Routinely used in such high-tech fields as electronics, automobiles, aircraft, and space vehicles, they are also essential to everyday staples of modern life, such as containers, piping, and appliances. Little wonder, when one considers their ease of fabrication, outstanding mechanical properties, design versatility, light weight, corrosion and impact resistance, and excellent fatigue strength. This Fourth Edition of the classic reference-the standard text for composite materials courses, worldwide-offers an unrivalled review of such an important class of engineering materials.

Still the most comprehensive, up-to-date treatment of the mechanics, materials, performance, analysis, fabrication, and characterization of fiber composite materials available, Analysis and Performance of Fiber Composites, Fourth Edition features:

- Expanded coverage of materials and manufacturing, with additional information on materials, processes, and material applications

- Updated and expanded information on experimental characterization methods-including many industry specific tests

- Discussions of damage identification techniques using nondestructive evaluation (NDE)

- Coverage of the influence of moisture on performance of polymer matrix composites, stress corrosion of glass fibers and glass reinforced plastics, and damage due to low-velocity impact

- New end-of-chapter problems and exercises with solutions found on an accompanying website

- Computer analysis of laminates

No other reference provides such exhaustive coverage of fiber composites with such clarity and depth. Analysis and Performance of Fiber Composites, Fourth Edition is, without a doubt, an indispensable resource for practicing engineers, as well as students of mechanics, mechanical engineering, and aerospace engineering.

Visit the Companion Website at: https://www.wiley.com/WileyCDA/Section/id-830336.html

BHAGWAN D. AGARWAL, PHD, is a former Vice President of engineering services at Bodycote Polymer-Broutman Laboratory, and Professor of Mechanical Engineering and Dean of Research and Development at the Indian Institute of Technology, Kanpur.

LAWRENCE J. BROUTMAN, PHD, is an independent consultant and founder of L.J. Broutman & Associates.

K. CHANDRASHEKHARA, PHD, is Professor of Mechanical and Aerospace Engineering and Director of the Composite Manufacturing Laboratory at the Missouri University of Science and Technology.

Updated and expanded coverage of the latest trends and developments in fiber composite materials, processes, and applications Analysis and Performance of Fiber Composites, Fourth Edition features updated and expanded coverage of all technical aspects of fiber composites, including the latest trends and developments in materials, manufacturing processes, and materials applications, as well as the latest experimental characterization methods. Fiber reinforced composite materials have become a fundamental part of modern product manufacturing. Routinely used in such high-tech fields as electronics, automobiles, aircraft, and space vehicles, they are also essential to everyday staples of modern life, such as containers, piping, and appliances. Little wonder, when one considers their ease of fabrication, outstanding mechanical properties, design versatility, light weight, corrosion and impact resistance, and excellent fatigue strength. This Fourth Edition of the classic reference'the standard text for composite materials courses, worldwide'offers an unrivalled review of such an important class of engineering materials. Still the most comprehensive, up-to-date treatment of the mechanics, materials, performance, analysis, fabrication, and characterization of fiber composite materials available, Analysis and Performance of Fiber Composites, Fourth Edition features: Expanded coverage of materials and manufacturing, with additional information on materials, processes, and material applications Updated and expanded information on experimental characterization methods'including many industry specific tests Discussions of damage identification techniques using nondestructive evaluation (NDE) Coverage of the influence of moisture on performance of polymer matrix composites, stress corrosion of glass fibers and glass reinforced plastics, and damage due to low-velocity impact New end-of-chapter problems and exercises with solutions found on an accompanying website Computer analysis of laminates No other reference provides such exhaustive coverage of fiber composites with such clarity and depth. Analysis and Performance of Fiber Composites, Fourth Edition is, without a doubt, an indispensable resource for practicing engineers, as well as students of mechanics, mechanical engineering, and aerospace engineering. Visit the Companion Website at: https://www.wiley.com/WileyCDA/Section/id-830336.html

BHAGWAN D. AGARWAL, PHD, is a former Vice President of engineering services at Bodycote Polymer--Broutman Laboratory, and Professor of Mechanical Engineering and Dean of Research and Development at the Indian Institute of Technology, Kanpur. LAWRENCE J. BROUTMAN, PHD, is an independent consultant and founder of L.J. Broutman & Associates. K. CHANDRASHEKHARA, PHD, is Professor of Mechanical and Aerospace Engineering and Director of the Composite Manufacturing Laboratory at the Missouri University of Science and Technology.

1

INTRODUCTION

1.1 DEFINITION

The word composite means “consisting of two or more distinct parts.” Thus, a material having two or more distinct constituent materials or phases may be considered a composite material. However, we recognize materials as composites only when the constituent phases have significantly different physical properties, and thus the composite properties are noticeably different from the constituent properties. The difference in properties will be more obvious when the properties of one constituent are much greater (≥5 times) than the other, when this phase is in fiber or platelet form, and its volume fraction is greater than 10%. Many combinations of constituents do not result in a new material with significantly different properties. Such materials are not classified as composites. For example, common metals almost always contain unwanted impurities or alloying elements; plastics generally contain small quantities of fillers, lubricants, ultraviolet absorbers, and other materials for commercial reasons such as economy and ease of processing, yet these generally are not classified as composites. In the case of metals, the constituent phases often have nearly identical properties (e.g., modulus of elasticity), the phases are not generally fibrous in character, and one of the phases usually is present in small-volume fractions. Thus, the modulus of elasticity of a steel alloy is insensitive to the amount of the carbide present, and metallurgists generally have not considered metal alloys as composites, particularly from the point of view of analysis. Nevertheless, two-phase metal alloys are good examples of particulate composites in terms of structure. Although plastics, which are filled with small amounts of additives to reduce cost, are composites, they need not be considered as such if their physical properties are not greatly affected by the additives.

Within the wide range of composite materials, a definition may be adopted to suit one's requirements. For the purpose of discussion in this book, composites can be considered to be materials consisting of two or more chemically distinct constituents, on a macroscale, having a distinct interface separating them. This definition encompasses the fiber composites, which are of primary interest in this text. This definition also encompasses many other types of composites that are not treated specifically in this book.

1.2 CLASSIFICATION

Composites consist of one or more discontinuous phases embedded in a continuous phase. The discontinuous phase usually has higher stiffness and strength than the continuous phase and is called the reinforcement or reinforcing material, whereas the continuous phase is termed the matrix. Ceramic matrix composites could be exceptions since matrix may have higher stiffness than the reinforcement. Properties of composites are strongly influenced by the properties of constituent materials, their distribution, and the interaction among them. Therefore, proper description of a composite material as a system requires, besides the constituent materials and their properties, the geometry of the reinforcement (shape, size, and size distribution) and its concentration, concentration distribution, and orientation with reference to the system.

Most composite materials have, so far, been developed to improve mechanical properties such as strength, stiffness, toughness, and high-temperature performance. The mechanism of improving these properties strongly depends on the geometry of the reinforcement. Therefore, it is quite convenient to classify composite materials on the basis of the microstructure of a representative unit of reinforcement to study together the composites that have a common strengthening mechanism. Figure 1.1 represents a commonly accepted classification scheme for composite materials. With regard to this classification, the distinguishing characteristic of a particle is that it is nonfibrous in nature with all its dimensions approximately equal. It may be spherical, cubic, tetragonal, a platelet, or of other regular or irregular shape. A fiber is characterized by its length being much greater than its cross-sectional dimensions. Particle-reinforced composites are sometimes referred to as particulate composites. Fiber-reinforced composites are, understandably, called fiber composites.

Figure 1.1. Classification of composite materials.

1.3 PARTICULATE COMPOSITES

Particle-reinforced composites are called particulate composites. A particle generally has no long dimension, with the exception of platelets. The dimensions of the reinforcement determine its capability of contributing its properties to the composite. Also, a reinforcement with a long dimension inhibits the growth of cracks normal to the reinforcement that otherwise might lead to failure, particularly with brittle matrices. Therefore, particles, in general, are not very effective in improving fracture resistance. However, particles of rubberlike substances in brittle polymers improve fracture resistance by promoting and then arresting crazing in the brittle matrices. Other types of particles, such as ceramic, metal, or inorganic particles, produce reinforcing effects in metallic matrices by different strengthening mechanisms. The particles, because they are harder than the matrix, restrict deformation of the matrix material between them and thus increase stiffness of the material. The particles also share the load, but to a much smaller extent than the fibers that are parallel to the load. Thus, the particles enhance the stiffness of the composites but do not offer much potential for strengthening. On the other hand, hard particles placed in a brittle matrix reduce strength because they produce stress concentrations in the adjacent matrix. Particle fillers, however, are used widely to improve other properties of matrix materials, such as the thermal and electrical conductivities, improve performance at elevated temperature, reduce friction, increase wear and abrasion resistance and machinability, increase surface hardness, and reduce shrinkage. In many cases, they are used simply to reduce cost.

The particles and matrix material in a particulate composite can be any combination of metallic and nonmetallic materials. The choice of a particular combination depends on the desired end properties. Particles of lead are mixed with copper alloys and steel to improve their machinability. In addition, lead is a natural lubricant in bearings made of copper alloys. Particles of many brittle metals such as tungsten, chromium, and molybdenum are incorporated into ductile metals to improve their elevated temperature performance while maintaining ductile characteristics at room temperature. Particles of tungsten, molybdenum, or their carbides are used widely in silver and copper matrices for electrical-contact applications, which require high thermal and electrical conductivities, high melting point, and low friction and wetting characteristics. These materials are also used for electrodes and related applications in the welding industry.

Cermets are composites of ceramic and metal. Oxide-based cermets are used extensively as tool materials for high-speed cutting, thermocouple protection tubes, furnace mufflers, and a variety of high-temperature erosive applications. Carbide-based cermets mostly have particles of tungsten, chromium, and titanium carbides. Tungsten carbide in a cobalt matrix produces very high surface hardness and is widely used in cutting tools, wiredrawing dies, valve parts, and precision gauges. Chromium carbide in a cobalt matrix is highly resistant to corrosion and abrasion and has a coefficient of thermal expansion close to that of steel. This makes it useful for valve parts, nozzles, and high-load bearings that operate at very high temperatures. Titanium carbide in a nickel or cobalt matrix is well suited for high-temperature applications such as turbine parts, torch tips, and hot-mill parts.

Inorganic fillers are extensively used to improve properties of plastics, such as surface hardness and shrinkage reduction, and to eliminate crazing in moldings, improve fire retardancy, provide color and improve appearance, modify the thermal and electrical conductivities, and, most important, greatly reduce cost without necessarily sacrificing the desirable properties. Many commercially important elastomers are filled with carbon black or silica to improve their strength and abrasion resistance while maintaining their necessary extensibility. Cold solders consist of metal powders suspended in thermosetting resins so that the composite is hard and strong and conducts heat and electricity. Copper in epoxy increases its conductivity immensely. Lead content in plastics acts as a sound deadener and shield against gamma radiation. Fluorocarbon-based plastics are being used as bearing materials. Metallic inclusions are incorporated to increase thermal conductivity, lower the coefficient of expansion, and drastically reduce the wear rate.

Thin flakes offer attractive features to be effective reinforcement. They have a primarily two-dimensional geometry and thus impart equal strength in all directions in their plane compared with fibers that are unidirectional reinforcements. Flakes, when laid parallel, can be packed more closely than fibers or spherical particles. Mica flakes are used in electrical and heat-insulating applications. Composites of mica flakes in a glassy matrix can be machined easily and are used in electrical applications. Aluminum flakes in paints and other coatings orient themselves parallel to the...

| Erscheint lt. Verlag | 26.10.2017 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie |

| Technik ► Maschinenbau | |

| Schlagworte | Bauingenieur- u. Bauwesen • Baustatik u. Baumechanik • Civil Engineering & Construction • Composites • computer analysis of laminates • corrosion of glass reinforced plastics • designing with fiber composites • Festkörpermechanik • Festkörpermechanik • fiber composite corrosion • fiber composite damage • fiber composite evaluation • fiber composite for airplanes • fiber composite low-impact damage • fiber composite material analysis • fiber composite material applications</p> • fiber composite material characterization • fiber composite material manufacturing • fiber composite material non-invasive evaluation • fiber composite material performance • fiber composite materials analysis • fiber composite materials testing • fiber composite mechanics • fiber composites • fiber composites in aerospace • fiber composites in automobiles • fiber composites in electronics design • fiber composites in product packaging • fiber composite stress analysis • Fiber Reinforced Composites • guide to fiber composite materials • <p>fiber composite materials • Maschinenbau • Materials Science • Materialwissenschaften • mechanical engineering • solid mechanics • Structural Theory & Structural Mechanics • Verbundwerkstoff • Verbundwerkstoffe |

| ISBN-10 | 1-119-38997-6 / 1119389976 |

| ISBN-13 | 978-1-119-38997-2 / 9781119389972 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich