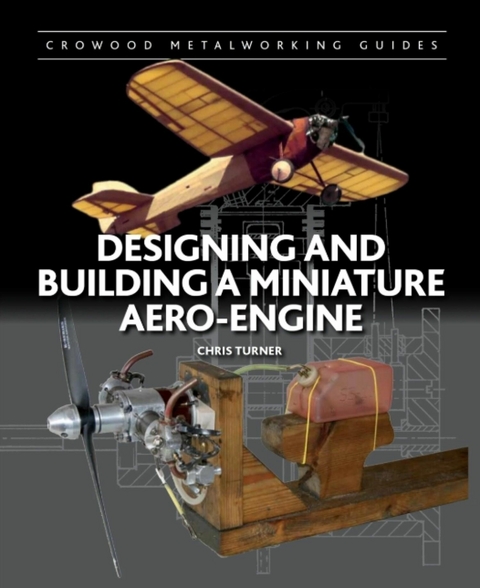

Designing and Building a Miniature Aero-Engine (eBook)

112 Seiten

Crowood (Verlag)

978-1-84797-777-9 (ISBN)

1 Tools and Materials

The tools and materials required for the production of miniature aero engines are much the same as those used by most model engineers, though with some special additions. Because of their small size much use is made of Swiss files, fine drills, small taps and dies, and especially ground ‘tool bits’. The author does not wish to set out an exhaustive list of the tools required because many of these are purchased when the need arises, and gradually accumulate over a long period. The emphasis will focus upon initial needs and how the modeller may proceed. Later chapters will mention special tools, ‘selfmade’ tools, and tools only relevant to the job in hand.

Full size aero engines use some rather exotic materials such as titanium and special steel alloys to allow lightness whilst giving adequate strength, and although miniature engines are not generally subjected to such high stresses, they do require special attention to these two factors because flight is, after all, the main goal. Much use is made of aluminium and its various alloys, and some special steels that offer greater strength and also stainless characteristics to combat corrosion. The metal-working processes needed to work these materials sometimes require tools that are especially modified or adapted to make the actual cutting more effective. This often necessitates modification of cutting angles by regrinding tool points, and in many cases, making tools from ‘sticks’ of tool steel (tool bits): these are easily purchased from suppliers (see list of suppliers).

Fig. 1-1: Assorted materials.

Of course this means that a fair degree of skill must be developed in the shaping of tools from very hard alloys by use of the bench grinder. This may seem a daunting task to those who are used to buying the ‘appropriate tool for the job’. There is a positive side to this though, as it is often difficult or impossible to obtain exactly the shape of tool needed to form a radius, make a recess, or bore that special hole. The requirement for different rake angles to suit the material being cut is another factor. Many tools bought ‘off the shelf’ have tungsten carbide inserts, which, although they may be shaped on a green grit wheel, are not as ‘modeller friendly’ as a simple tool-steel ‘tool bit’, which allows the constant regrinding and reshaping often required because it is used for different materials and opera-tions. Such tool bits may be sharpened and reshaped until eventually, like a well worn pencil, there is nothing left but a stub – and even this may sometimes be used in a fly cutter or maybe at the end of a boring bar.

Fig. 1-2: Small tool bit in a boring bar.

The development of the skills needed to sharpen twist drills and other tools on the bench grinder may only be achieved by experience. It is a good thing to enlist the help of an experienced fellow modeller or friend, or join a college class (often full of model engineers!), and so have some very valuable instruction. This is possibly most important from the safety point of view, as grinding wheels can be dangerous if they are not used properly, particularly in their maintenance where there is a requirement for dressing and ‘truing’ with a diamond. Technical colleges often arrange safety certificate courses which cover the methods of dressing and setting of tool rests, and general maintenance to ensure your ‘wheel’ is safe.

Special tools normally made by the modeller are also necessary to cater for the task of holding parts that will not fit in a conventional chuck, or which need accurate location relative to one another, or need a guide to ensure accurate alignment. These may include drill jigs to ensure the repeatability of holes relative to each other, milling and turning fixtures to hold difficult shapes, and pilot mandrels to ensure the alignment of parts being pressed together – for example, the assembly of bushes in connecting rods and suchlike.

Drawings are available for many useful tools designed for home construction for use in the lathe and milling machine. ‘Hemingway Kits’ (see list) offer a comprehensive catalogue of kits for making many tools which are either not available ‘off the shelf’ or are very expensive. A typical example is their precision boring head, which is most useful in the manufacture of accurate holes for the engine builder – for example, holes in a crankcase for the location of cylinders. Other tools include a ‘clamp-type’ knurling tool which, unlike the usual tool obtained from suppliers, exerts little or no side force on the lathe tool post as it clamps the work being knurled between two wheels.

Some tools require the use of castings, and these may be supplied as part of the kit along with all the other materials necessary, saving the modeller the problem of ordering small, uneconomical quantities of special materials such as phosphor bronze, which may be expensive in small quantities.

The manufacture of these special tools is really part of the design process for the miniature engine maker, because the designer must resolve the problem of how the parts are to be made, which includes all the engineering processes and tools required. The more complicated the engine, the greater the need for tools specially made for individual purposes. This part of the design process is often quite a challenge and every bit as interesting and rewarding as making the engine itself.

HAND TOOLS

Files and Saws

Files and saws are among some of the most important tools for all engineers. They may appear old fashioned, but a good grounding in their use forms the basis of most engineering processes. An understanding of the need to have datum edges – of making surfaces flat and square to each other – underpins all the more sophisticated operations, whether they are hand or machine, or even computer controlled. To this end it is good practice to take every opportunity to use saws and files, and the checking and measuring instruments, until it becomes second nature to use them, rather than depending upon more complex machining methods which often take time to ‘set up’.

Hacksaws

Hacksaws are needed for the general cutting of metals in the bench vice. These saws are capable of holding a range of blades, the most useful being twenty-four and thirty-two teeth per inch. It is better to purchase good quality blades of an alloy steel capable of cutting the various materials that make up the engine than to compromise with cheaper blades that don’t last. Manufacturers often state the material their blades will cut.

Fig. 1-3: Saws.

Junior hacksaws are needed for cutting small thicknesses and where the large hacksaw may be unwieldy. This saw leaves a narrower ‘kerf’, has smaller teeth, and exerts less pressure on the work. Fig. 1-3 shows a full size hacksaw capable of taking 10in and 12in blades at the top, a junior hacksaw in the middle, and a piercing saw at the bottom.

Files

There is a multitude of different types and sizes of file from which to choose. Most useful for small work are 6in, 8in and 10in flat, round, and square section, smooth and second-cut files. For the finest work, Swiss or needle files are required, and for cutting very hard materials, diamond files. These may be bought in a handy wallet of assorted shapes which normally suffice for most work (see Fig. 1-4).

Other shapes and sizes may be added as and when needed. Many model makers keep a set of new, or nearly new files especially for use on brass, because brass is a material which demands a sharp-toothed file. This material can be quite hard, and there is often a tendency for the file to ‘skate’ over the surface without cutting. File handles for all files are normally supplied separately.

Fig. 1-4: Example of diamond files.

Hammers

Hammers are very useful tools in the right hands; the model engine maker will use them most frequently to apply judicious blows to pin punches, centre punches, and parts reluctant to slide by hand. Much skill may be exercised in directing a measured tap in the right place, and in the lathe the use of a hide mallet in order to ‘true up’ a piece of raw material prior to final tightening of the chuck can become a very useful skill.

Most useful are ball pein hammers, particularly small ones for delivering a sharp but accurate tap exactly where it is needed and the ‘ball pein’ part is essential if riveting parts together. Hide mallets or mallets with a nylon or soft metal facing find their uses too, for delivering measured blows to ensure parts are in contact with the parallel strips in the vice when setting up for milling, because parts sometimes tend to ‘ride up’ when being tightened in some vices. Despite the violent nature envisaged by some, hammers are essential when used correctly.

Slip Stones

Slip stones (India stones) are another useful hand tool, particularly for dressing seatings for ball races because they remove very small amounts of metal, leaving the surface smooth and polished. They may also be used for dressing tool points between regrinds.

Slip stones are available in various types of grit and...

| Erscheint lt. Verlag | 31.8.2014 |

|---|---|

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Modellbau |

| Technik ► Bauwesen | |

| Technik ► Maschinenbau | |

| ISBN-10 | 1-84797-777-4 / 1847977774 |

| ISBN-13 | 978-1-84797-777-9 / 9781847977779 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

DRM: Digitales Wasserzeichen

Dieses eBook enthält ein digitales Wasserzeichen und ist damit für Sie personalisiert. Bei einer missbräuchlichen Weitergabe des eBooks an Dritte ist eine Rückverfolgung an die Quelle möglich.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich