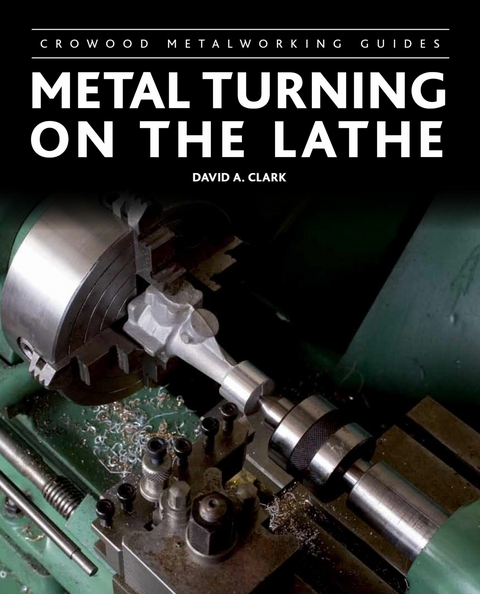

Metal Turning on the Lathe (eBook)

268 Seiten

Crowood (Verlag)

978-1-84797-641-3 (ISBN)

The lathe is an essential tool for all but the most basic of workshops. It enables the engineer to produce turned components to a high degree of accuracy. Often called the 'king of machine tools', it is also very versatile and can be used to make a wide range of engineering components. This new book shows you how to make full use of your lathe safely and effectively in your workshop. Topics covered include: a guide to choosing a lathe looking at different sizes and features available; advice on installing and maintaining a lathe, selecting and sharpening tools, and working with chucks, and finally, instruction is given on a range of techniques ranging from how to hold work in a collet through to cutting a screw thread.

WHAT SIZE OF LATHE DO I REQUIRE?

The first thing to consider when buying a lathe is the size of the work that you want to do. What is the largest diameter you will want to turn on it and what is the longest length you will need to turn? A 3½ × 18in (90 × 457mm) lathe will allow a maximum diameter of 7in (178mm) to be turned over the lathe bed; the latter figure is known as the swing. In practice, though, this is a theoretical maximum as it is still necessary to hold and clamp the article being turned. The swing over the cross slide is usually much smaller, typically 2in (50mm).

Many lathes, however, are manufactured with a gap bed at the headstock end to enable short items of a large diameter, such as locomotive or traction engine wheels, to be turned.

Lathes are also sometimes available as standard and long bed lathes. The long bed lathe, as the name suggests, allows longer material to be turned within the capacity of the lathe. When turning longer material, the diameter will be limited by the swing over the cross slide. This will be a lot smaller than the swing over the bed.

If building a model such as a traction engine or a locomotive, the deciding factor for the size of lathe is likely to be the diameter of the largest pair of wheels that need to be turned. Before deciding on the size of lathe required you should determine the size of the largest diameter and the longest length of material that needs to be turned. Another factor in determining what lathe to buy is the availability of spares and accessories: is the company still trading, will it still be trading in the future, and are there large amounts of second-hand parts and accessories available from tool dealers or on eBay?

A typical inverter to convert 240 volts single phase to 240 volts 3 phase.

LATHE ELECTRICS

Single phase electric is where the lathe plugs into the mains supply in your house. The motor will have the usual live, neutral and earth leads. Lathes supplied for factory use usually have three phase motors and require three live wires, each of a different phase. Think of a phase as an incoming wave on the seashore; three successive waves make up the three phases needed. Each phase is the same as the preceding one but they are out of sync and all peak at a different time.

A forward/reverse control box for an inverter.

Converters and inverters

You can run some 3 phase motors from a single phase supply via a converter or an inverter. The motor information plate will usually say 240 volts/440 volts if it is capable of running on an inverter. Inside the motor there will be changeover tags to change the motor from 440V down to 240V. Follow the converter/inverter manufacturer’s instructions for further information. It is not usually very complicated to run a 240V 3 phase motor from an inverter and this will give a quieter and smoother running motor than a single phase supply can provide. This usually requires some simple programming, explained in the inverter’s instructions, and it usually takes five minutes to get the motor working properly.

This motor is part of the inverter package shown in the previous illustration. No wiring is involved as the motor lead plugs straight into the inverter box.

The inverter runs at a constant voltage but the speed of the motor will change as the frequency is raised or lowered. I suggest limiting your inverter from full speed to half speed so that the fan still cools the motor and stops it from overheating; you can then use the belts to change the main speed steps as usual. (If you must use very slow running it is possible to add a separate fan, such as a computer cooling fan, to give constant airflow.) Most inverter suppliers offer a forward/reverse and speed control box that can be set up in a convenient position on the machine. These are well worth fitting for convenience in use.

This inverter is designed for mounting on the front of the lathe.

While inverters are designed to run only one machine, you can get converters to power more than one machine at a time. Depending on the size and power output, converters cost about three to four times as much as an inverter.

There are two main types of converter. Rotary converters are designed to run more than one motor at a time. This is ideal if you want to run more than one machine or two motors on one machine, for example the main machine motor and perhaps an auxiliary motor that drives the machine’s coolant pump or power feed system.

A rotary converter capable of powering more than one 3 phase motor.

The second type is the static converter, which is designed to run one motor at a time. There is, of course, nothing to stop you using the static converter on more than one machine by fitting a suitable female electrical connector to the static converter and matching male connectors to the individual machines. This way you can connect the static converter to only one machine at a time.

This static converter is suitable for powering one 3 phase motor. If you fit a socket on the output, however, different individual machines can be plugged into it, one at a time.

The electrical loading on rotary or static converters must not exceed their maximum rating. If in doubt on the load capacity needed to run your machine(s), you should consult the manufacturer or supplier of the converter.

An earth leakage trip is ideal for quickly eliminating a motor where the electrical insulation is breaking down. It is useful for detecting certain electrical earthing faults but should not be used as a guarantee of electrical safety.

Simple electrical testing and safety

When buying a small single phase second-hand lathe, take with you an earth leakage tester of the type used for lawn mowers and other garden tools. I once bought a Unimat 3 lathe, took it home and plugged it in. It kept blowing the earth leakage trip in the fuse box, even though it had worked perfectly at the seller’s house. I sold it on at a loss but the buyer did know there was a problem with the electrics.

It is most important that the metal parts of any lathe are connected to the earth wire, which is in turn connected to earth. Make sure that the motor frame is also connected to earth as some motors have dampening rubber mounts that insulate them from the machine itself. If in doubt about any aspect of electrical installation, please consult a qualified electrician.

A continuous bed is ideal when working with the faceplate or with collets.

LATHE BED

The lathe bed is the backbone of the entire lathe and is the part that is mounted on the bench or stand. There are two main types of lathe bed: the plain bed and the gap bed. The plain bed is usually continuous all the way along its length while the gap bed has, as its name suggests, a gap in the bed. This is not a literal gap but a stepped section that allows bigger diameters to be turned than you would otherwise be able to turn on a plain bed lathe. This gap is a means of making a lathe smaller than would be required for a plain lathe able to turn a similar size of component.

Some continuous lathe beds have a section next to the headstock that can be removed to increase the diameter that can be turned. This feature is usually only fitted to larger lathes such as are mostly found in factories.

Some lathes have hardened beds although most are just plain cast iron. There are three main types of bed ways, called shears: the plain flat bed with square ways, a bed with a flat top and a 60 degree dovetail at each side, and a bed with raised and inverted Vee ways. On the last of these the tailstock usually runs on one set of Vees and the carriage on a different set of Vees, resulting in less wear to the main slides. Wide beds are better and more accurate, as the lathe carriage is less likely to twist on a wide bed.

Close-up view of a typical lathe bed with a gap. A gap bed lathe has a larger turning diameter capacity than the equivalent sized continuous bed lathe.

Some very early lathes, such as those made by Drummond, had a round bed. Although they worked well, there is no adjustment for wear in the lathe bed.

The Myford range of lathes has a square form of bed.

This type of bed has a flat top with an inverted Vee at each side. The Vees are usually set at 60 degrees but can vary with different makers.

The Unimat SL lathe was sold for many years and many second-hand examples are still available. This model differs from most lathes in that it has two steel bars as a bed. This is not a problem, however, as the Unimat is intended only for very small and lightweight model-making work and there is the advantage that the bed can be replaced by fitting new bars.

When buying a second-hand lathe, it is most important to check the condition of the bed. You need to make sure the bed is reasonably free from dings, rust and hacksaw marks. Hacksaw marks near the headstock are often caused by sawing off work while it is held in the chuck; dings are usually caused by dropping the chuck on the lathe bed when screwing it on or off the mandrel. A simple chuck board placed on the bed while fitting or removing the chuck will protect the bed....

| Erscheint lt. Verlag | 16.12.2022 |

|---|---|

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Heimwerken / Do it yourself |

| Sachbuch/Ratgeber ► Freizeit / Hobby ► Kreatives Gestalten | |

| Technik ► Bauwesen | |

| Technik ► Maschinenbau | |

| ISBN-10 | 1-84797-641-7 / 1847976417 |

| ISBN-13 | 978-1-84797-641-3 / 9781847976413 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich