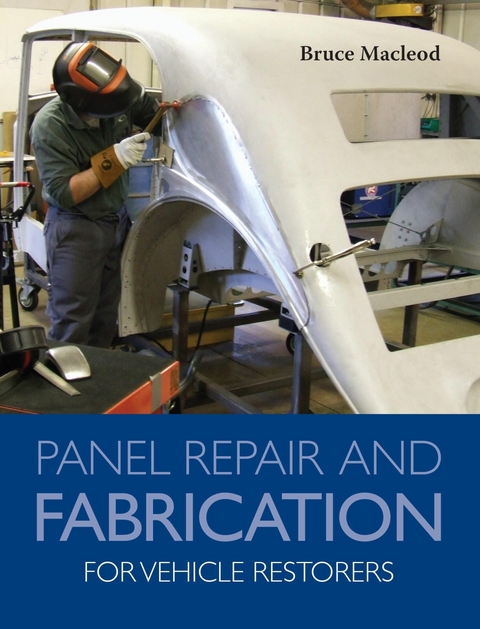

Panel Repair and Fabrication for Vehicle Restorers (eBook)

192 Seiten

The Crowood Press (Verlag)

978-0-7198-4474-4 (ISBN)

Initially learning his craft from his father, who trained as a coachbuilder, Bruce Macleod has a lifetime's experience that covers all aspects of vehicle body construction and repair. As a highly regarded authority in his craft, Bruce has trained countless professionals and amateurs in the techniques of making body panels and the restoration of vehicle bodies, and has previously authored Welding for Vehicle Restorers.

Chapter One

Health and Safety

Health and safety should always be taken seriously as severe injury and long-term health conditions can result from a lack of awareness and a lack of discipline in using protective measures. To reduce the risk of harm to yourself and others it is always necessary to understand the risks and use the appropriate protective equipment. It is important to develop safe working habits, as a moment of lapse in concentration when working on vehicles can cause serious injury. Tiredness plays a part in many accidents, so avoid carrying out any operations using power tools or other dangerous equipment when feeling fatigued.

Working alone increases the risk of harm, as you are more likely to lift something that is too heavy and can be unaware of other incidents in the workshop, such as a fire starting, when you are concentrating on a particular job. The environment you are working in can create risks: many household garages have a poor floor surface, a leaky roof and outdated electrics, all of which increase the chances of an accident occurring.

To reduce the risk of injury or harm when working on a vehicle always carry out a visual risk assessment before you begin.

RISK ASSESSMENT AND APPROPRIATE PPE

Exposure to Fumes

All paint, oxides and electroplating should be removed from the surface of the metal panel prior to welding to avoid creating any toxic fumes that may be produced when these are burnt. Avoid welding close to rubber seals or other combustible materials that are likely to give off noxious fumes when heated. A fume mask should be worn and/or effective fume extraction used where there is any risk of fumes being produced. Portable fume extractors are available for this purpose.

Fumes created during the welding of metals have been found to cause cancer when exposure to these takes place over a long period of time; there are no guidelines at present as to what constitutes a safe level of exposure. An air-fed mask is the best option to protect against this risk if carrying out any significant amount of welding.

Exposure to Heat

When welding or heating metal, gloves should always be worn to protect hands and wrists from burns. It is also necessary to protect arms and legs from any burns that may be caused by weld spatter or contact with a hot panel by wearing suitable clothing. Short-sleeved shirts and short trousers should not be worn whilst welding or working on vehicle bodywork as this significantly increases the risk of cuts and burns to exposed skin.

Gloves used for MIG welding should have a high level of heat resistance with long enough cuffs to protect the user’s wrists from burns caused by any weld spatter and the intense light, both of which are produced during the process.

Exposure to Electric Shock

Welding machines and electric power tools pose a serious risk of electric shock. Never use these in wet, damp or highly humid conditions. Ensure that all cables are kept dry and in good condition. Electrically powered tools and machinery should always be connected to the mains current through an appropriately rated electrical circuit breaker.

Exposure to the Intense Light Created by the Welding Process

It is important to protect the eyes from the flash of light that is created by the welding process as this may cause temporary blindness and long-term sight problems if they are subjected to regular exposure. A suitable face mask is an essential piece of equipment for use during welding. A range of varying shades is available, depending on the type of welding employed and the amperage used: a higher amperage will produce a brighter flash during welding, requiring a higher level of protection. Metals such as aluminium are highly reflective, and a higher level of light will be experienced when welding these than when welding mild steel.

Sharp Edges on Metal Panels

Suitable gloves that offer protection from cuts should always be worn when handling sheet metal. Gloves are available in a wide range of different designs and materials. Some offer more cut protection, others more protection from burns or a better grip. I have found that leather is the best material to offer all-round protection and give a reasonable degree of grip. When welding, the standard leather rigger glove, which has a safety cuff to protect the wrist, offers better heat protection than thinner TIG welding gloves when handling hot metal. The disadvantage in wearing thicker gloves is that they provide less control over the torch button, so I usually wear a thick rigger glove on the hand holding the panel and a thinner TIG glove on the torch hand to give a better feel for operating the trigger.

HEALTH AND SAFETY MEASURES

Risks

The appropriate personal protective equipment (PPE) should be used to reduce the risk of harm to yourself and others, as there are serious health issues that can arise from carrying out work on vehicle panels and bodies. These might be caused by any of the following:

• Fumes

• Heat

• Electric shocks

• Intense light created by the welding process

• Sharp edges to metal panels

• Trip and slip hazards

• Movement of heavy objects

Grinding metal is also a common cause of many injuries, which might arise from any of the following:

• Sparks

• Dust

• Projectiles

• Noise

• Vibration

Health and Safety Equipment

• Fume mask – designed to filter out fumes created by welding, grinding or sanding.

• Gloves – heat and cut resistant. Vibration-resistant gloves should be worn when using power tools.

• Welding mask, of a type that is appropriate to the welding process.

• Face shield – use a full-face screen to protect the face from projectiles or splashes.

• Goggles – close-fitting to protect the eyes from dust, projectiles or splashes.

• Ear protection – ear defenders or ear plugs that are suitable for the particular purpose.

• Fire extinguisher – CO2 or equivalent to combat fire in a vehicle or workshop.

Vibration from Power Tools

Vibration-resistant gloves should be worn if working using a power tool over a long period of time to avoid the fingers becoming numb, and possible long-term damage to the nerves. These gloves cushion the hand against the shock created by vibrating tools.

A range of leather gloves used for working with, and welding, metal. Left to right: rigger glove, used for general handling of metals; TIG welding glove; heavy duty welding glove.

Padded, vibration-resistant gloves that protect the user from injury caused by the prolonged use of reciprocating power tools that create significant vibration.

Chemicals

Chemical-resistant gloves must be worn when working with acids, thinners or paint to protect against damage that can cause dry and cracked skin, and the ingestion of chemicals through the skin. To avoid contamination of other surfaces that may be touched after using any of the above, you should have specific gloves for handling the various different substances being used.

Polyurethane-coated gloves should be worn when using chemicals to protect the hands from chemical burns and the ingestion of harmful liquids through the skin.

All chemicals and compounds that are used when cleaning and preparing panels for paint are generally harmful, so all precautions should be taken to avoid breathing in the fumes given off, or allowing the chemical or compound to come into contact with the skin or eyes. Keep a bottle of medical eye wash in the workshop, in a conspicuous place, so that any splashes of harmful liquids or dust can be immediately washed out of the eyes.

Eye wash should be kept in a prominent position in the workshop so that it can be easily accessed to flush out any dust or chemicals as quickly as possible.

A full-face screen should be worn to protect eyes and face from splashes, and a suitable fume mask should be worn to avoid breathing in harmful fumes.

Trip and Slip Hazards

The cables from extension leads, earthing leads and welding torches create trip hazards and should be kept as tidy as possible and put away when not in use.

Any dust produced during the grinding or sanding of metals creates a slippery surface when it falls on to a smooth concrete floor. Sweep up dust and filings at regular intervals to reduce the risk of slipping on these.

Risk of Movement of Heavy Objects

Gas bottles should be stored securely; if free standing, they need to be chained to a wall or a permanent structure. A falling gas bottle presents a risk of crush injury, and harm from high-pressure gas that could be released if the valve is damaged or broken off. Gas bottles are best stored in a mobile trolley to ensure they can’t be accidentally knocked over, and so they can be moved easily to avoid physical injuries that can be caused by lifting or moving such a heavy object. Protective footwear should always be worn in a workshop as there is a high risk of injury to the feet from heavy objects being dropped on them.

Gas bottles should be secured to a bench or solid structure, or stored in a suitable trolley, to avoid the possibility of them being accidentally knocked over.

Ensure that any vehicle...

| Erscheint lt. Verlag | 17.3.2025 |

|---|---|

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Natur / Technik ► Fahrzeuge / Flugzeuge / Schiffe ► Allgemeines / Lexika |

| Natur / Technik ► Fahrzeuge / Flugzeuge / Schiffe ► Auto / Motorrad | |

| Schlagworte | Auto body sheet metal forming • Classic car body panels • Classic car body repair • Classic car body restoration • classic car restoration • English wheel metal forming • Forming sheet metal • Forming sheet metal by hand • Historic vehicle restoration • Making aluminium body panels • Making auto body patch panels • Making car body repair panels • Making steel body panels • Shaping body panels • Shaping sheet metal • Shaping sheet metal with hand tools • Sheet metal body panels • Sheet metal body repair • Sheet metal fabrication • Sheet Metal Tools • Sheet metalwork • Sheet metalworking • Vehicle body restoration |

| ISBN-10 | 0-7198-4474-6 / 0719844746 |

| ISBN-13 | 978-0-7198-4474-4 / 9780719844744 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

DRM: Digitales Wasserzeichen

Dieses eBook enthält ein digitales Wasserzeichen und ist damit für Sie personalisiert. Bei einer missbräuchlichen Weitergabe des eBooks an Dritte ist eine Rückverfolgung an die Quelle möglich.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich