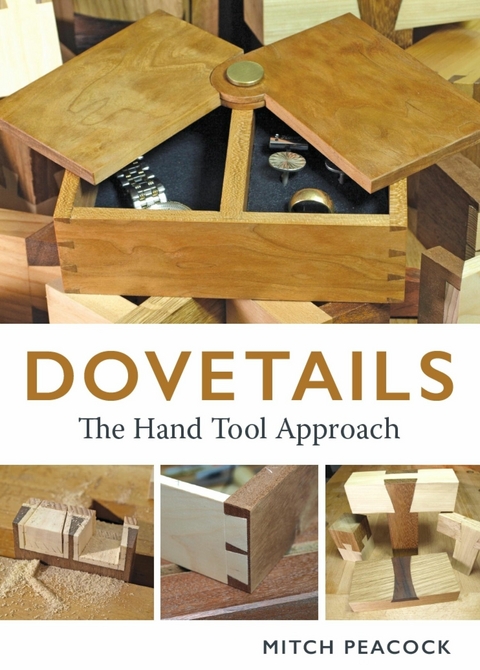

Dovetails (eBook)

160 Seiten

The Crowood Press (Verlag)

978-0-7198-4446-1 (ISBN)

Mitch Peacock is a retired engineer who has been designing and making with wood for over two decades. Almost entirely self-taught, he also teaches many others, in person, online and through magazine articles. He is best known online for his mastery of hand-crafted joints, both Western and Japanese. Mitch is a regular contributor to Woodworking Crafts and Furniture & Cabinetmaking magazines, and also contributes to a number of other woodworking magazines and forums. Over the years, Mitch has completed a number of private, retail and clerical commissions, and now makes a limited number of woodworking tools, alongside the occasional interesting commission.

TECHNIQUES

T his chapter introduces woodworking techniques – tips or tricks if you like – that could easily fill a book by themselves. I’ll cover those that should help in your dovetail joinery. Those techniques that I feel will help most in terms of accuracy, appearance and speed, plus some alternatives to the standard dovetailing techniques, are given in further chapters.

Stanley No. 71 router plane in action. A router plane is not essential for hand-cut dovetails, but is certainly desirable. Small router planes are especially useful for smaller corner joints in cabinet making.

SAWING TRUE AND PLUMB

Joints that need to slide together, such as the dovetail joints in this book, require well mating surfaces. In the case of dovetail joints, and others, these mating surfaces are flat, and are produced primarily by sawing with a rigid blade. Apart from the initial stage of a cut, the rigid blade helps to guide the saw on a straight path. With this in mind, it is crucial to start cuts correctly. Until this becomes second nature to you, follow the two-line and three-line methods, and practise making sets of parallel plumb cuts each time you go to the workshop.

The Two-Line Method

The two-line method is quickest, requiring only two marking-out lines to saw up against, and relying on this initial sawing to maintain the plane in which the saw continues to complete the cut. This is also the method where any lap is required, with the remaining cut being made with chisels.

The saw cut can be advanced along either one or both of the lines to start with. If both, then the cut proceeds until the teeth reach the ends, whereupon the third side is cut by sawing whilst pivoting the toothline at the bottom of the first line.

If you find that watching both lines at the same time is too difficult, it is possible to start the saw cutting against just one marking line, across the top, only to half bury the teeth – this sets the toothline in one direction, then saw down against the second line whilst pivoting the toothline at the far end. From there, the cut is completed as before.

Sawing plumb using the two-line method, with twin-line start. Follow the top and front marking line to begin with, before completing the cut.

Starting the two-line method for sawing plumb by first sawing a kerf to half the tooth height. Then concentrate on following the vertical line.

Three-Line Method

For through dovetails, a three-line method, although slower, is advisable when cutting large joints in thick boards, where a small deviation of saw-plate angle can show up as a significant error on the reverse side of the board.

Proceed as the two-line method, but to cut the third side, reverse the work and follow the third mark-out line, pivoting the toothline in the top cut. This leaves an internal triangle to saw through, guided by the kerfs on each side.

For sawing thicker boards, the three-line method can be used to help assure plumb cuts on both faces of the board.

TIPS FOR SAWING TAILS AND PINS

Always try to cut into the show surface of tail- and pinboards, so that you can see where to stop, and so that any fibre tearout is on the reverse side.

Tails

• Tilt the tailboard in the vise at the same slope as the dovetails, so that you can saw plumb to the workbench: this should be easier than sawing with the saw tilted over. Don’t forget to reposition the board when sawing the other side of the tails.

• Gang multiple tailboards together, and cut as one. The extra width helps to keep the cuts square.

Pins

• Clamp a bevel gauge to the pinboard, set to the angle you are cutting. This gives you a much longer reference against which to align the saw plate.

• Stand at an angle to the bench so that your shoulder, elbow, wrist and the saw all line up with the direction you need to cut.

CHOPPING AND PARING

The importance of sharp tools is a prerequisite to good joint preparation, but even the sharpest edge can produce unwanted effects. In dovetail joinery we are mostly concerned with the use of chisels to remove waste and leave flat joint surfaces, but we must be aware of their tendency to both grip material and act as a wedge.

Wedge Effect of a Chisel

Since a standard chisel bevel is on just one side of the blade, as the chisel is driven into the wood, the wedge effect exerts a force on the chisel towards the non-bevel side or back. The chisel is pushed out of line with where it started, as can be seen above. All the care taken to knife the shoulder (or baseline) of the joint can easily be wiped out.

To minimise the wedge effect, material on the bevel side of the chisel should be cleared as much as possible. There are two main ways to achieve this: either by sawing the waste away close to the shoulder line with a fretsaw or similar, or by notching out the waste, bit by bit, initially staying shy of the shoulder line.

When chopping waste with a chisel, the bevel acts as a wedge and moves the back of the chisel through the knifed shoulder line.

Clockwise from top left: to preserve a knife line, first make a shallow chop offset slightly from the line, then notch out to the depth of the chop and chop again. Repeat until close to full depth, before chopping directly on the line.

Chip Grab

‘Chip grab’ is the term I use to describe the plucking out of end-grain material by a chisel. Most notably this appears to happen on softer woods, especially wood softened by spalting or other causes. This soft wood seems to grab the sharp edge, resisting a push cut, and a chip is pulled from the end grain.

Chip grab should be predicted and then avoided by sawing as much waste as possible, carefully, and then paring with gentle shearing cuts using a freshly honed chisel with a low bevel angle.

Material can be pulled from the end grain when chopping pin or tail waste, in what I call ‘chip grab’. Learn how to predict it, so that you can take avoiding action.

A sharp chisel with a low bevel angle and a side-to-side action is usually sufficient to avoid chip grab in tight spots between pins or tails.

Prediction comes from previous experience of a wood species, and testing offcuts from as close as possible to the area to be cut. Shearing cuts in tight spaces, such as between tails or pins, can be achieved by side-to-side sweeps of the chisel tip.

PARING TO LINES

Precise joinery uses knife lines for marking out. A single bevel knife, held perpendicular to the surface, leaves a sharp, perpendicular, and well defined line for registration of a chisel edge. Saw cuts can be made just shy of these lines, removing the majority of the waste, before final paring cuts are made with a chisel, using the knife line as a reference for the chisel back. An example of the process of paring to the lines is shown below.

The example shows a case where paring cuts can be made from three different directions, but a similar approach can be taken in other situations.

The steps recommended when paring waste from a knifed corner for precise joinery. Top left: Upwards from the knife line, from two opposite sides. Top right: A third cut is made from the adjacent side to the first two, leaving an angled hump of waste with a clear knife shelf around its perimeter. Bottom right: Thin paring cuts are now made parallel to the knife shelf, without risk of removing the knife lines. Bottom left: Final waste is removed while keeping the chisel edges flat on the knife lines and shy of the board edges, to leave a perfect flat plane.

EXCAVATING CORNERS

To prepare wholly precise dovetails it is necessary to remove waste right up into some acute corners. There is a workaround for where these corners do not meet a show surface, but first let us look at the basic problems and the appropriate solutions.

Through Dovetails

A regular bevel-edge chisel can cut into the corner between a tail side and the shoulder of a through-dovetail tailboard, but its small square section below the bevels will restrict its access when cutting between tails if used square to the tailboard.

By taking a narrower chisel and skewing the cut, the tip of the chisel can reach right into the base of the tail unencumbered, and the waste can be pared away cleanly.

Lapped Dovetails

In lapped dovetails of any kind, pinboards have acute corners between three surfaces – the bottom, back and side of the sockets. The sides of the sockets, the pin surface, can be accessed with a normal bevel-edge chisel, but the bottom and back of the socket cannot be cleaned right into the corner.

To cut right into this acute corner, a slim, pointed knife blade can be used, although a pair of dedicated skew chisels are easier to use and produce a clean cut. The skew of the chisel tip prevents the non-cutting corner of the blade from fouling the back of the socket when paring the bottom, and vice versa. A pair of skew chisels are required to reach both left and right corners.

A simple solution for paring the internal corners is to skew the chisel a little. To do this, the chisel must be considerably narrower than the gap between the tails.

There is a potential access problem when paring square between tails, due to the shape of the chisel. However, accessing the...

| Erscheint lt. Verlag | 28.11.2024 |

|---|---|

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Heimwerken / Do it yourself |

| Sachbuch/Ratgeber ► Freizeit / Hobby ► Kreatives Gestalten | |

| Schlagworte | AWL • cabinetry • Carpentry • carpentry techniques • chisel • chiselling • corner joints • dovetail box • Dovetails • furniture making • Gauge • hand tools • JIGS • joinery • joints • lapped dovetails. • Plane • Planning • puzzle joints • sawing tails and pins • three-line method • two-line method • Woodworking |

| ISBN-10 | 0-7198-4446-0 / 0719844460 |

| ISBN-13 | 978-0-7198-4446-1 / 9780719844461 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

DRM: Digitales Wasserzeichen

Dieses eBook enthält ein digitales Wasserzeichen und ist damit für Sie personalisiert. Bei einer missbräuchlichen Weitergabe des eBooks an Dritte ist eine Rückverfolgung an die Quelle möglich.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich