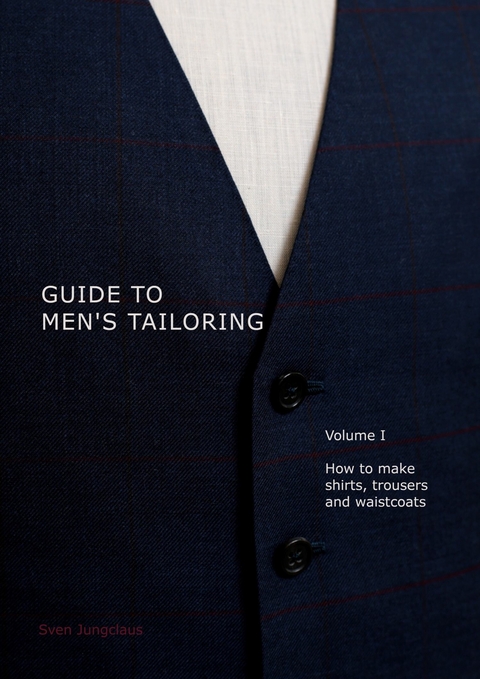

Guide to men's tailoring, Volume I (eBook)

132 Seiten

Books on Demand (Verlag)

978-3-7534-2877-2 (ISBN)

Sven Jungclaus hat seine Ausbildung zum Damen- und Herrenmaßschneider in den 90er Jahren bei Heinz-Josef Radermacher in Düsseldorf absolviert. Bereits damals hat er für Musicalproduktionen wie Grease und Forever Plaid in Düsseldorf oder Die Schöne und das Biest und Tanz der Vampire in Stuttgart gearbeitet. Nach acht Jahren an der Bayerischen Staatsoper in München als Herrenschneider und Herrengewandmeister hat er sein Fachwissen an der Royal Shakespeare Company in Stratford upon Avon, der Deutschen Oper am Rhein in Düsseldorf und den Salzburger Festspielen weiter vertieft. Seit März 2013 fertigt er in seiner Gewandmanufaktur in Salzburg maßgeschneiderte Kleidung für Damen und Herren. Zusätzlich arbeitet der vielseitige Maßschneider immer wieder für die Kostümwerkstatt Das Gewand in Düsseldorf und wird für Opern oder Musical-Produktionen angefragt - z. B. für die Metropolitan Opera in New York, die Nationalsje Opera in Bergen, das Theater Basel, das Musical Chicago in Stuttgart und Berlin, Het Muziektheater in Amsterdam, die Salzburger Festspiele oder das Theater of Nations in Moskau. ------------------------------------------- Sven Jungclaus has completed his training as a bespoke lady's and men's tailor in the 1990s with Heinz-Josef Radermacher in Dusseldorf. Already at that time, he worked for musical productions like Grease and Forever Plaid in Dusseldorf as well as The Beauty and the Beast and The Fearless Vampire Killers in Stuttgart. After eight years at the Bavarian State Opera in Munich as a master tailor and head of men's costume, he has deepened his expertise at the Royal Shakespeare Company in Stratford upon Avon, the Deutsche Oper am Rhein in Dusseldorf and the Salzburg Festival. Since 2013, he has been producing bespoke clothing for men and women in his tailor shop Gewandmanufaktur in Salzburg. In addition, the versatile tailor works again and again for the costume workshop Das Gewand in Dusseldorf and is requested for operas or musical productions e.g., the Metropolitan Opera in New York, the Nasjonale Opera in Bergen, the Theater Basel, the Musical Chicago in Stuttgart and Berlin, Het Muziektheater in Amsterdam, the Salzburg Festival or the Theater of Nations in Moscow.

4

Link to the

shirt videos

https://www.becomeatailor.com/videos-shirt/

Cutting the shirt

Before cutting, it is essential to wash the fabric - which is usually made of cotton or linen - in the washing machine with the gentle or wool program at 30° C. The fabric can shrink significantly. With prewashing, the collar fits even after processing and when the shirt will be rewashed. The seam allowances are marked as indicated in the drawing. Otherwise, at least the seam allowance of 0.75 or 1 cm is marked everywhere (see also explanation on page →).

5

6

7

8

9

10

11

12

The cutting

Pictures 5/6

When cutting the shirt, you do not necessarily have to pay attention to the threading unless you work with corduroy, flannel or something similar.

For white fabrics, drawing the cutting parts carefully with a thin, soft pencil is advisable. These marks will be removed with the next washing.

The back darts

Picture 7

With pins, the dart is transferred and retraced to the other side.

Picture 8

Then, the darts are folded at the dart-center-line and pressed.

Picture 9

When stitching, the seam must be locked at the beginning and the end (sewing back and forth). After that, the darts are ironed flat toward the side seam.

The lower flap

Picture 10

The edge of the right front part - the lower flap/ bracket - is first folded by 1 cm and ironed flat, then folded by 3 cm and ironed flat to the wrong side of the fabric.

A strip of adhesive interlining can be added inside to reinforce the lower flap for holding the buttons. Now, the lower flap is sewn from the back very narrow to the edge (about 1 - 2 mm).

The button bar

Picture 11

The edge of the left front piece, the button bar, is folded and ironed twice by 3 cm. The cutting edge has to lie precisely in the fold. A strip of adhesive interlining can be added inside to reinforce the button bar.

Then, the edge is stitched by approx. 5 mm.

After that, the front part is folded back and ironed flat.

For symmetry, stitch the button bar on the other side by approximately 5 mm.

Picture 12

Left and right finished edges placed side by side.

13

14

15

16

17

18

19

20

The back yoke

Picture 13

First, the inner back yoke is placed on the back. Facing the right fabric side of the yoke onto the left side of the back part and stitched with a narrow seam (0.5 cm).

Picture 14

The outer back yoke is then stitched with a regular wide seam (0.75 cm) on the back, facing the right fabric side of the yoke to the right side of the back.

Picture 15

Afterwards, both back yokes are ironed up one after the other. The back yoke can be fixed with a narrow seam (1 mm) if desired.

The sleeve vent

The binding and placket are stitched approximately 5 mm at the sleeve vent. The binding is on the narrow side, and the placket is on the wider side.

Picture 16

Now, the vent is cut open, and the corners at the end are pinched like a triangle until just before the last seam stitch.

Picture 17

The binding is now folded and ironed twice by 0.5 cm and then stitched through at the top. If desired, the binding can also be hand-stitched with blind stitching and then machine-stitched from the top.

Now the binding is stitched together with the triangle; this way, the slit looks clean inside.

Picture 18

The placket is first folded and ironed by 1 cm and then by 2 cm. The end of the placket can be pointed or straight as you wish.

Picture 19

Then, the placket is stitched from the top. You have to be careful so that the placket is well caught. It is safer to hand-stitch the placket with a blind stitch and then machine stitch from the top.

Picture 20

Now, the back of the sleeve vent looks clean and well-finished.

21

22

23

24

25

26

27

28

The shoulder seam

Picture 21

The shoulder of the front part is sewn to the back yoke with a narrow seam (5 mm) facing the right fabric sides together. (Attention, do not swap right and left shoulder)

Picture 22

Then, the front part with the left side of the fabric is put on the right side of the 2nd back yoke and stitched together with a regular seam (0.75 cm).

It's a bit unwieldy, but you get used to it. Alternatively, the shoulder seam of the inner back yoke can also be pressed over by the width of the seam allowance and blind stitched by hand to the shoulder seam.

Picture 23

After that, the shoulder seam is carefully ironed flat.

Attaching the sleeve

For a better fit, cut off approx. 1 cm at the front sleeve head (f=front). This also results in better freedom of movement, as the arms tend to be taken more forward.

Picture 24

At the sleeve head, the cutting edge is folded down to the right side by approximately 0.75 cm. The picture shows the right side of the fabric. In the beginning, one often believes that it is wrong, but it will be explained in picture 28.

Pictures 25/26

Now, place the armhole's edge into the sleeve head's fold, facing the right fabric sides together. Ensure that the front part is pinned to the front section of the sleeve head.

Picture 27

Then, the sleeve is sewn onto the shirt. While sewing, the sleeve faces down to the sewing machine while the rest of the shirt lies on top. It is sewn on the front, back, and yoke, not the sleeve.

Picture 28

Finally, the seam is ironed flat so the previously folded sleeve head encloses the seam allowance of the armhole.

29

30

31

32

33

34

35

36

Wrapping the sleeve head seam

Picture 29

On the wrong side (the inside) of the fabric, the folded seam allowance is now fixed to the armhole with pins or a basting stitch.

Picture 30

Then, this folded seam can be fixed with a prick stitch (see page →), which is approximately 0.75 cm wide. If you wish, the seam can also be stitched by machine.

With both methods, it is essential to ensure that the folded seam allowance is secured when sewing.

Picture 31

Finally, the seam is ironed flat again and should be smooth and without any tension.

Closing the side seam

Picture 32

The side seam is first assembled at the crossing point of the sleeve seam and the side seam, facing the wrong sides together. Then, the seam is pinned down to the hem and up at the sleeve. After that, the seam is stitched by approximately 0.75 mm.

Picture 33

Then, the seam allowance is cut back cleanly to approximately 5 mm.

No individual fringes should protrude. Otherwise, you will see this later on the outside of the side seam.

Picture 34

The seam allowance is now ironed flat in one direction on the sleeve board. The closed sleeve is then turned inside out.

Picture 35

Now, the seam is ironed flat from the wrong side and stitched again with a regular seam (0.75 cm). This closes the side seam and makes it look clean inside.

Picture 36

Finally, the sleeve is turned inside out, and the seam is folded and ironed flat to the back. The seams at the armhole and the side seam should look like a cross and fit together perfectly. If care was taken when cutting back (picture 33), no fringes of the seam allowance should now protrude.

37

38

39

40

41

42

43

44

The cuffs

Picture 37

The entire cuff is first fused with a thin interlining to the wrong side of the fabric. Then, a thicker interlining is cut exactly in the shape of the cuff and fused to the previous fused interlining.

Picture 38

Now, the cuff is folded together, facing the right fabric sides together. At the lower side of the cuff, the seam allowance of 0.75 cm is folded up.

Then, the cuffs are stitched at the sides by 1 mm next to the thick interlining.

Picture 39

The seams are ironed flat, the seam allowances are graded down, and the corners are cut back.

Picture 40

Then, the cuff is turned inside out and ironed flat.

Picture 41

The fullness of the sleeve hem is placed in a fold, which is open towards the sleeve slit. (Some patterns may have 2 or 3 pleats)

Picture 42

Now, the cuff is put to the sleeve, facing the right side of the cuff to the right side of the sleeve. It should be ensured that the binding and the placket of the sleeve vent fit precisely into both ends of the...

| Erscheint lt. Verlag | 27.1.2021 |

|---|---|

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Handarbeit / Textiles |

| Schlagworte | bespoke • Men • sewing • Tailor • Tailoring |

| ISBN-10 | 3-7534-2877-9 / 3753428779 |

| ISBN-13 | 978-3-7534-2877-2 / 9783753428772 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Größe: 67,6 MB

DRM: Digitales Wasserzeichen

Dieses eBook enthält ein digitales Wasserzeichen und ist damit für Sie personalisiert. Bei einer missbräuchlichen Weitergabe des eBooks an Dritte ist eine Rückverfolgung an die Quelle möglich.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich