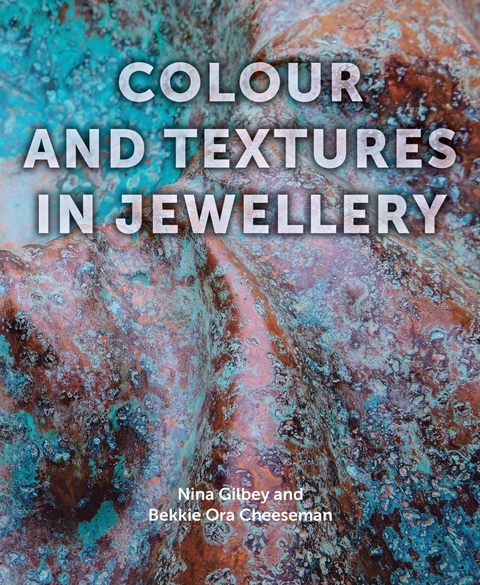

Colour and Textures in Jewellery (eBook)

208 Seiten

Crowood (Verlag)

978-1-78500-578-7 (ISBN)

Nina Gilbey was trained in jewellery and silversmithing at The Cass and later graduated with a masters degree from the School of Jewellery in Birmingham. With a background in fine art, she is interested in the relationship between line and form , and how negative spaces create a solid void. She is passionate about working with metal, using traditional techniques to explore and challenge its inherent qualities. She has been teaching the subject for many years, and founded London Jewellery Workshop in 2011 to offer a student-led environment, promoting inspiration and creativity.

Nina Gilbey was trained in jewellery and silversmithing at The Cass and later graduated with a masters degree from the School of Jewellery in Birmingham. With a background in fine art, she is interested in the relationship between line and form , and how negative spaces create a solid void. She is passionate about working with metal, using traditional techniques to explore and challenge its inherent qualities. She has been teaching the subject for many years, and founded London Jewellery Workshop in 2011 to offer a student-led environment, promoting inspiration and creativity.

CHAPTER 1

Embossed Textures

The techniques described in this chapter can be used to create an embossed texture. By using a variety of tools, it is possible to imprint a pattern, design or detail on to the surface of the work. These techniques include hammering, stamping and roll printing.

HAMMERING

A wide variety of textures can be achieved by hammering directly onto the metal surface. The imprint created will depend on the shape of the hammer head, as well as the amount of force administered.

The great advantage of the hammering process is that you have control over the uniformity and depth of the strike. With a steady hand, keeping control of the movement and placement of the hammer blow, it is possible to create a consistent texture.

Ready-made embossing hammers can be purchased, or you could create your own by filing and marking the hammer face. Here, the more traditional technique of commonly used hammers is demonstrated.

When hammering onto a flat surface, rest the metal sheet on a steel flat plate. Hold the hammer at the end of the handle, supporting the metal with the other hand, and strike directly onto the metal.

Hammers (from left to right): forging, jobbing, raising, ball pein, planishing, chasing, embossing and riveting hammers, nylon and hide mallets, and steel flat plates.

HEALTH AND SAFETY

•Check the hammer head is secure before beginning to work; if not, secure it first to prevent it from flying off.

•Always ensure fingers are out of the way of where the hammer will strike.

•Support work on a former whenever possible to prevent the metal from distorting.

•Hold the hammer at the end of the handle and bend from the elbow to prevent injury to the wrist.

Planishing hammer

The planishing hammer is used to finely shape and smooth metal surfaces. To create a texture, the hammer face should be tilted in different directions to produce small facets. This hammer should only be used on a curved surface, as on a flat sheet the hammer or the piece could be damaged.

Hammering with a riveting hammer, securing the metal sheet on a steel block.

Using a planishing hammer to texture a curved surface.

Ball pein hammer

This hammer, also known as a ball peen or machinist hammer, has a rounded end. Traditionally used to harden metal, it can also be used to create small dimples on the metal surface. You can choose to mark the metal densely or with gaps between hammer blows, creating different textures. The effect can be altered further by hammering with a softer or harder strike.

Dense ball pein hammered texture.

Spaced ball pien hammered texture.

Riveting hammer

Also known as a jeweller’s hammer, this is available in a number of sizes. One end of the hammer head has a small flat surface; the other end has a narrow pien. This narrow part can be used to create small linear marks, which can be struck in line, cross-hatched or used haphazardly.

Riveting hammer texture with linear marks

Riveting hammer texture with crossed-hatched marks.

Riveting hammer texture with diagonal and crossed-hatched marks.

Texturing hammer

These hammers have a variety of shapes and marks etched into the hammer face. When used they imprint their design onto the metal surface. It can be difficult to achieve an even texture because a lot of these hammers have regular repetitive patterns and a strike would have to be exact if an even texture was desired.

Texture created using an embossing hammer.

Mallet

Mallets are made of rawhide, nylon or wood. Mallets are used for shaping and forming metal. They cannot be used to create a texture directly as they are not hard enough, but they can be used in conjunction with other tools and materials.

Metal wrapped in binding wire and hammered using a hide mallet.

Metal overlaid with sandpaper and hammered using a hide mallet.

Almost any material can be used to apply a texture to the metal surface. Ensure the metal is annealed, pickled and dried. Using a mallet you could try hammering onto coarse sandpaper placed face down onto the metal surface. Some other effective texturing materials include wrapping binding wire around the metal and hammering it, or placing metal onto asphalt. All of these will create an imprint on the metal surface.

HAMMERING TIPS

•Hold the hammer at the end of the handle, not at the top. This gives a more consistent strike.

•If you strike with the edge of a hammer head you may create facets on its face which will impact on its use, or the hammer head may become loose.

•Remember: a metal hammer marks metal; a mallet shapes metal.

•Hammering metal will harden it, so anneal as necessary.

•Hammering an item such as a ring with a steel hammer will stretch the metal and make it larger in size.

•Keep hammer heads clean and polished for best results.

Hammering gallery

Oblique spoon by Nina Gilbey. Sterling silver, hand forged and textured with a planishing hammer. PHOTO: HATTON GARDEN STUDIOS

Ring by David Hardy. Multiple techniques have been used to create this oxidized sterling silver piece, including hammering, fold forming, granulation, reticulation and stone setting. PHOTO: CIQO PHOTOGRAPHY

Ring by Natalia Maja Majewska of Bibba London. Hammered and oxidized silver, with hammered granulation in silver, red and yellow gold. PHOTO: BIBBA LONDON

Ring by Mathew Hall, oxidized sterling silver and 18ct yellow gold with a faceted aquamarine stone. The surface has been hammered and filed to create a bark-like antique finish. PHOTO: MH GOLDSMITH JEWELLERY

STAMPING

Many styles of decorative stamps are available which can be used to create an imprint of shapes, imagery or lettering. Alternatively your own design can be made if required, by yourself or by a tool maker.

The process

The metal should always be supported on a hard surface such as a steel block, a mandrel or something in the shape of your piece. If the supporting surface isn’t hard, stamping will create a dent rather than a clear mark.

Stamping tools including letters, numbers and shapes, both bought and handmade.

Stamping with a mallet supported on a steel plate, with the little finger supporting the hand holding the stamp.

To stamp an impression onto the metal, first make sure that the metal is annealed, then rest your little finger on the steel flat plate and hold the stamp at the top between fingers and thumb. Ensure the stamp is at a 90° angle to the metal. Strike the top of the stamp just once with a mallet to create a clear impression.

It can be difficult to create a regular pattern with consistent gaps between stamp marks. This requires practice and in some cases it is necessary to clamp your metal in place and carefully mark where the stamp should strike.

Making a stamp

Cut a length of round or square tool steel and anneal it to a bright red colour; alternatively an old tool made of tool steel can be recycled. Allow it to cool completely without quenching.

Annealing a length of tool steel in preparation for shaping a stamp.

Shaping the tip of the tool steel to create the desired pattern.

Tempering the tool steel to reduce brittleness.

Close-up of the colour range of tempered steel.

Taper the tip of the tool using a rough file. The longer the taper, the easier it will be to see where the tool is placed on the piece. Carve a design into the tip of the tool using files, a piercing saw, burrs or gravers. Avoid undercuts or very deep grooves, and check the impression repeatedly by pushing the tip into plasticine.

Once the shaping of the stamp is complete, it needs to be hardened. Heat the decorative end until it’s bright red, then quench straight away in water or oil, such as olive oil. This will harden the steel but will also make it brittle, so it is then necessary to temper it. Tempering will soften it slightly while keeping its strength.

When tool making, each type of tool requires a different hardness, therefore they should be tempered appropriately. The colour of the steel indicates its hardness: for example, scrapers are heated to a blue colour, wood chisels are heated to an orange/red, and stamps are heated to a straw yellow colour.

Use emery paper to clean the whole length of the stamp until all the black oxides are removed and the steel is shiny. Hold the flame about 1.5 inches or 3.5 cm from the decorative tip and heat it gradually. The tip itself should not be heated. The metal will change colour to blue and eventually a yellow, straw colour will appear. The straw yellow colour will travel towards the tip; then quench immediately in water. If the tip gets any hotter than straw coloured, the process will need to be repeated. The tool is now tempered and ready to use.

HEALTH AND SAFETY

•In some cases, such as when marking a curved piece of metal, it is necessary to secure the metal so that it...

| Erscheint lt. Verlag | 27.5.2019 |

|---|---|

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Heimwerken / Do it yourself |

| Sachbuch/Ratgeber ► Freizeit / Hobby ► Kreatives Gestalten | |

| Schlagworte | annealing • anodised aluminium • beaded colour palette • Casting • chemical colouring • cold moulds • Colour • craft • cuttlefish casting • Design • earrings • Embossing • enamelling • engraving • Etching • gemstone book • Gemstones • gilding • Glass • gold leaf • Granulation • hammering • hot moulds • jewellery • Jewellery book • keum boo • kiln enamel • kiln-formed glass • Lost wax casting • Making • making bracelets • married metals • metal finishing • microwave glass • Mixed Media • mould making • oxidising • patination • plaster moulds • Plating • Polishing • Resin • reticulation • roll printing • Sand Casting • soldering • Something Special • Stamping • texture • torch enamel • Wood |

| ISBN-10 | 1-78500-578-2 / 1785005782 |

| ISBN-13 | 978-1-78500-578-7 / 9781785005787 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

DRM: Digitales Wasserzeichen

Dieses eBook enthält ein digitales Wasserzeichen und ist damit für Sie personalisiert. Bei einer missbräuchlichen Weitergabe des eBooks an Dritte ist eine Rückverfolgung an die Quelle möglich.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich