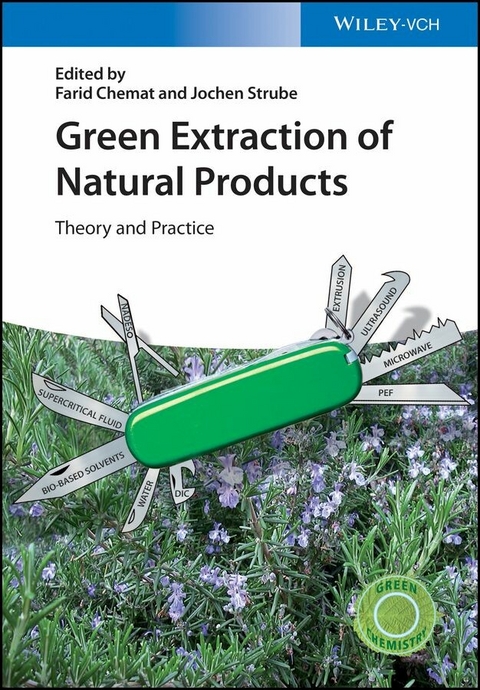

Green Extraction of Natural Products (eBook)

384 Seiten

Wiley-VCH (Verlag)

978-3-527-67681-1 (ISBN)

Farid Chemat is a full Professor of Chemistry at Avignon University (France), Director of GREEN Extraction Team (alternative extraction techniques and solvents), co-director of ORTESA LabCom research unit Naturex-UAPV, and scientific coordinator of 'France Eco-Extraction' dealing with dissemination of research and education on green extraction technologies. Born in 1968, he received his PhD degree in process engineering from the Institut National Polytechnique de Toulouse-France in 1994. After periods of postdoctoral research work with Prolabo-Merck (1995-1997), he spent two years (1997-1999) as a senior researcher at the University of Wageningen (The Netherlands). In 1999, he moved to the University of La Réunion (France DOM) as an assistant professor and since 2006 holds the position of Professor at the University of Avignon (France). His main research interests are focused on innovative and sustainable extraction techniques, protocols and solvents (especially microwave, ultrasound and bio-based solvents) for food, pharmaceutical, fine chemistry, biofuel, and cosmetic applications. His research activity is documented by more than 140 scientific peer-reviewed papers, 9 books and 7 patents.

Jochen Strube is a full Professor of Chemical and Biotechnology Engineering and Director of the Institute for Separation and Process Technology at Clausthal University of Technology (Germany). Together with Hansjörg Hagels from Boehringer Ingelheim he currently leads the German working group of industry and academics for 'Plant-based Extraktion -- Products and Process' of ProcessNet at Dechema e.V. Frankfurt am Main. Born in 1965, he received his Dr.-Ing. (1992) and Habilitation/'venia legendi' (2000) degree in Chemical Engineering at the University of Dortmund. From 1999 - 2006 he worked for Bayer AG Leverkusen, Germany. Since 2006 he has been Director of the Institute for Separation and Process Technology in Clausthal. His main research interests are focused on predictive model-based design of separation processes for complex mixtures such as plant-based extracts or fermentation broths and validation with mini-plant technology. Under his initiative the institute was re-directed with a fully equipped mini-plant technology under ATEX for industrial applications of higher value products in regulated environments like pharmaceutics, biologics, botanics, cosmetics, flavors, nutrition and nutraceuticals etc. His research activity is summarized by over 130 scientific peer-reviewed papers, 9 books and 6 patents.

Farid Chemat is a full Professor of Chemistry at Avignon University (France), Director of GREEN Extraction Team (alternative extraction techniques and solvents), co-director of ORTESA LabCom research unit Naturex-UAPV, and scientific coordinator of "France Eco-Extraction" dealing with dissemination of research and education on green extraction technologies. Born in 1968, he received his PhD degree in process engineering from the Institut National Polytechnique de Toulouse-France in 1994. After periods of postdoctoral research work with Prolabo-Merck (1995-1997), he spent two years (1997-1999) as a senior researcher at the University of Wageningen (The Netherlands). In 1999, he moved to the University of La Réunion (France DOM) as an assistant professor and since 2006 holds the position of Professor at the University of Avignon (France). His main research interests are focused on innovative and sustainable extraction techniques, protocols and solvents (especially microwave, ultrasound and bio-based solvents) for food, pharmaceutical, fine chemistry, biofuel, and cosmetic applications. His research activity is documented by more than 140 scientific peer-reviewed papers, 9 books and 7 patents. Jochen Strube is a full Professor of Chemical and Biotechnology Engineering and Director of the Institute for Separation and Process Technology at Clausthal University of Technology (Germany). Together with Hansjörg Hagels from Boehringer Ingelheim he currently leads the German working group of industry and academics for "Plant-based Extraktion -- Products and Process" of ProcessNet at Dechema e.V. Frankfurt am Main. Born in 1965, he received his Dr.-Ing. (1992) and Habilitation/"venia legendi" (2000) degree in Chemical Engineering at the University of Dortmund. From 1999 - 2006 he worked for Bayer AG Leverkusen, Germany. Since 2006 he has been Director of the Institute for Separation and Process Technology in Clausthal. His main research interests are focused on predictive model-based design of separation processes for complex mixtures such as plant-based extracts or fermentation broths and validation with mini-plant technology. Under his initiative the institute was re-directed with a fully equipped mini-plant technology under ATEX for industrial applications of higher value products in regulated environments like pharmaceutics, biologics, botanics, cosmetics, flavors, nutrition and nutraceuticals etc. His research activity is summarized by over 130 scientific peer-reviewed papers, 9 books and 6 patents.

Green Extraction: From Concepts to Research, Education and Economical Opportunities

Process Engineering and Product Design for Green Extraction

Tailormade Production of Plants for Green Extraction

Mass Transfer Enhancement for Solid-Liquid Extractions

Fundamentals of Process-Intensification Strategy for Green Extraction Operations

Panorama of Sustainable Solvents for Green Extraction Processes

Supercritical Fluid Extraction: A Solvent with Variable Geometry

Water as Green Solvent for Extraction of Natural Products

Comprehensive exploitation of residues from olive oil, wine, citrus juice and related agriculture

Selective Extraction from Food Plants and Residues by Pulsed Electric Field

Green Extraction of Artemisinin from Artemisia annua L.

Chapter 1

Green Extraction: From Concepts to Research, Education, and Economical Opportunities

Farid Chemat, Natacha Rombaut, Anne-Sylvie Fabiano-Tixier, Jean T. Pierson, and Antoine Bily

1.1 Introduction

One of the principal aims of sustainable development of green processing is in the teaching of green chemistry in colleges, high schools, and academic laboratories of both developed and developing nations. The researchers from academia and professionals from industry have chosen not to ignore the potential consequences of green chemistry and processes and have realized that they have responsibilities in education, research, and acceptance for industrial implementation of green chemistry (analysis, extraction, synthesis, separation, etc.) [1]. They recognize that their research will affect the future of the planet with the creation of new products and processes that improve the quality of life and reduce environmental hazards [2–4]. The implementation of green chemistry technologies minimizes the use of materials that are hazardous to human health and environment [5], decreases energy and water usage, and maximizes efficiency (Figure 1.1).

Figure 1.1 Impact of green chemistry in changing industrial and academic practices.

Extraction of natural products has been used probably since the discovery of fire. Egyptians and Phoenicians, Jews and Arabs, Indians and Chinese, Greeks and Romans, and even the Mayans and Aztecs, all possessed innovative extraction processes (maceration, alembic distillation, etc.) used even for perfume, medicine, or food. However, during the 1990s, it was not easy to find literature concerning the dispersed efforts for greening the extraction practices. It was necessary to wait for the tremendous development of green chemistry made by the Environmental Protection Agency (EPA) and led by Paul Anastas [3], who published a series of fundamental books from 1994 trying to create a general conscience on the need for green chemistry.

Recent trends in extraction techniques have largely focused on finding solutions that minimize the use of solvent and energy, such as supercritical fluid extraction, ultrasound extraction, subcritical water extraction, controlled pressure drop process, pulse electric field, and microwave extraction. The tremendous efforts made in greening extraction processes can be evaluated through the consideration of books devoted to these aspects as can be seen in Figure 1.2. Theoretical and practical efforts are absolutely necessary to convince the members of the chemical societies about the need for such a revolution in our mentality and practice.

Figure 1.2 Books devoted to green extraction of natural products.

To meet the requirements of the market and to abide by the regulations in force, any extraction process must meet a number of quality criteria, contrary to some popular misconceptions; the “natural” state of an extract is no guarantee of its harmlessness to humans and the environment. In such a changing context, we must now switch over from a simple interest in data analysis to interest in models to a strong consideration of the environmental side effects of our practices as a consequence of the high demands of the extraction processes. This evolution or revolution in the extraction of natural products is summarized in Figure 1.3. Green extraction of natural products could be a new concept to meet the challenges of the twenty-first century, to protect both the environment and consumers, and at the same time enhance competition among industries to evolve more ecologic, economic, and innovative methods. Within the green extraction approach, the concept of the green extract is that of an extract obtained in such way as to have the lowest possible impact on the environment (lower energy and solvent consumption, etc.) and whose eventual recycling would have been planned for (coproducts, biodegradability, etc.). The green extract should be the result of a whole chain of values in both senses of the term, that is, economic and responsible, starting from the production and harvesting of the plant, the transformation process of extraction, and separation together with formulation marketing.

Figure 1.3 Extraction of natural products: evolution or revolution.

Various industrial sectors, such as pharmaceutical, cosmetic, and food industries have increasing needs in natural products. They are obtained from plant or animal resources through extraction processes. In order to meet demand and fulfill regulations, the extraction processes are challenged to increase extraction efficiency (yield and selectivity toward compounds of interest), reduce or eliminate petrochemical solvents, together with moderate energy consumption. Within these constraints, green extraction has been recently introduced on the basis of green chemistry and green engineering further referring to modern “sustainable processes.” In relation to green extraction of natural products, its definition has been given by Chemat et al. [2]: “Green Extraction is based on the discovery and design of extraction processes which will reduce energy consumption, allows use of alternative solvents and renewable natural products, and ensure a safe and high quality extract/product.” The listing of the six principles of green extraction of natural products should be viewed for industry and scientists as a guideline to establish an innovative and green label, charter, and standard, and as a reflection to innovate not only in process but in all aspects of solid–liquid extraction. The principles have been identified and described not as rules but more as innovative examples to follow, discovered by scientists and successfully applied by industry.

- Principle 1: Innovation by selection and use of varieties of renewable plant resources

- Principle 2: Use of alternative solvents, principally water or bio-based solvents

- Principle 3: Reduction in energy consumption by energy recovery, using innovative technologies

- Principle 4: Manufacture of coproducts instead of waste to include the bio- and agro-refining industries

- Principle 5: Reduction in unit operations, favoring safe, robust, and controlled processes

- Principle 6: Aiming for a non-denatured and biodegradable extract without contaminants.

This chapter aims at specifying the notion of natural products and illustrating how natural products can be used as ingredients in different industrial sectors. For this, we limit ourselves to compounds obtained from the plant kingdom. The biomolecule composition of a vegetable cell is usually divided into two major groups: primary and secondary metabolites. The former refers to key compounds in plant metabolism, and the latter to compounds which are involved in specific functions in the plant. Croteau et al. [6] introduced the term plant natural product to designate secondary metabolites, due to their biological activity and role in plant ecology. The expression “natural product” is today broadly used to designate extracts obtained from plants containing specific compounds, possessing a technological, functional, or nutritional application [7, 8]. Using the example of the orange tree as a veritable biorefinery, a few valuable metabolites are evidenced. The chemical structure and diversity of the different classes of metabolites in the plant kingdom are then reviewed. Some applications of natural products as ingredients are ultimately presented.

This chapter also presents as ultimate examples, the successful application of green extraction of natural products in academia as a vector of green teaching and research and also in industry, presenting a continuous challenge for innovation and competitiveness.

1.2 Orange Fruit is not Limited to Produce Only Juice?

The pattern from metabolites to ingredients can be illustrated through the example of the orange tree. The major industrial use of oranges is juice production. However, the known diversity of the phytochemical composition of the fruit and the orange tree allows considering the tree as a biorefinery of natural products. The following section describes the by-product valorization of orange juice production along with some examples of the phytochemicals identified in the orange tree and fruit.

With a total production of 68 million tons in 2012 [9], orange is one of the major crops in the processing industry. Out of the total production, 95% is used to manufacture orange juice. Considering that 3 kg of oranges are necessary to produce 1 l of orange juice, there is a great potential for valorization of the by-products generated [10]. Further, not only the by-products from the fruits but also the whole orange tree can be used for nutritional, pharmacological, or cosmetic purposes. In this section, the pathways for valorization of orange products are described. Different types of by-products can be generated from orange juice production: those from the orange tree and those from the orange itself. By-products generated by orange juice production are pulps, peels, and seeds [10, 11].

One of the main by-products obtained from the orange fruit is the pulp (42.5% w/w of orange waste) [9, 12]. Owing to their high fiber content, pulps are mainly used for livestock feeding. Moreover, inclusion of the pulp in cattle feed would support growth and lactation in a better way than would starch-rich supplements...

| Erscheint lt. Verlag | 11.3.2016 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie |

| Technik | |

| Schlagworte | chemical engineering • Chemie • Chemische Verfahrenstechnik • Chemistry • Extraktion • Grüne Chemie • Green Chemistry, Extraction, Natural Products, Process engineering, Process Intensification, Green Solvents • Grüne Chemie • Industrial Chemistry • Nachhaltige u. Grüne Chemie • Nachhaltige u. Grüne Chemie • Pharmaceutical & Medicinal Chemistry • Pharmazeutische u. Medizinische Chemie • Process Engineering • Prozesssteuerung • Sustainable Chemistry & Green Chemistry • Technische u. Industrielle Chemie |

| ISBN-10 | 3-527-67681-3 / 3527676813 |

| ISBN-13 | 978-3-527-67681-1 / 9783527676811 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich