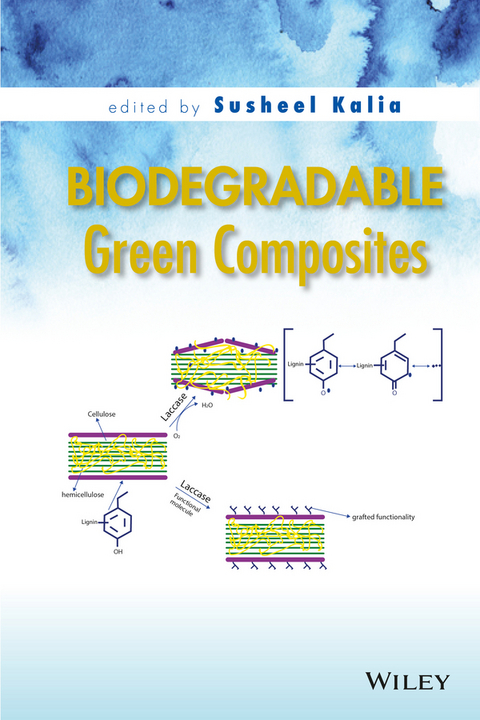

Biodegradable Green Composites (eBook)

John Wiley & Sons (Verlag)

978-1-118-91091-7 (ISBN)

Susheel Kalia is Researcher in Department of Civil, Chemical, Environmental and Materials Engineering at University of Bologna, Italy. Kalia's research is in the field of biocomposites, nanocomposites, conducting polymers, cellulose nanofibers, inorganic nanoparticles, hybrid materials, hydrogels and cryogenics. The author of many international papers, articles and chapters, he has published many review articles on polymeric composites based on natural fibers. Kalia's editorial activities include work as a reviewer and memberships of editorial boards for various international journals. He is also a member of a number of professional organizations, including the Asian Polymer Association, Indian Cryogenics Council, the Society for Polymer Science, Indian Society of Analytical Scientists, and the International Association of Advanced Materials.

1

BIODEGRADABLE GREEN COMPOSITES

Sreerag Gopi1,2, Anitha Pius1, and Sabu Thomas2

1 Gandhigram Rural University—Deemed University, Dindigul, Tamil Nadu, India

2 International and Inter University Centre for Nanoscience and Nanotechnology, Mahatma Gandhi University, Kottayam, Kerala, India

- 1.1 Introduction

- 1.2 Biodegradable Polymers

- 1.3 Nanofillers for Composites

- 1.4 Nanocomposites from Renewable Resources

- 1.5 Processing of Green Composites

- 1.6 Applications

- 1.7 Conclusion

- References

1.1 INTRODUCTION

Conventional polymers are usually made from petroleum resources such as polyolefins, and they are ideal for many applications such as packaging, building resources, commodities, and consumer goods. Polyolefin-based plastics have become a foundation of modern civilization and are low cost, durable, resistant to solvents, waterproof, and resistant to physical aging. The resistance of polyolefin materials to degradation by microorganisms is both an advantage and, in the long term, a problem. It was estimated in 2002 that some 41%·w/w of the total global plastic production was used by packaging industries, with 47% of that production being used to package foodstuffs [1]. Most oil-derived packaging is nonrecyclable, or economically impractical to recycle, and quickly becomes landfill, equating to a huge quantity of nondegradable waste. Microorganisms found in landfill soils are unable to degrade conventional plastics [2], and as a result, they remain in the environment for a very long time [3]. This in itself has not been a huge concern until recently. Landfills are unattractive to residents living near them, and new ones are costly and difficult to establish. Landfills are becoming filled to capacity with more waste generated every day due to continued expansion of human urban areas and population increases. Recycling plastics is one possible solution, and since the early 1990s, more and more plastic waste is subject to recycling across developed nations [4, 5]. Australia recycled 18.5% (282,032 t) of the total plastics collected in 2008, and 58.2% of that amount was recycled here with the remainder exported for reprocessing [6]. Despite this admirable effort, it still leaves a phenomenal amount of waste plastics. Recycling is not without its problems since often recycled polymers are contaminated, resulting in inferior mechanical properties to feedstock created ones [7]. This reduces recycled feedstock desirability and hence the economic benefit to recycling. Polymer waste can also be disposed of by incineration, but given the current political climate on greenhouse emissions, this is becoming unfeasible. Incineration also produces harmful gasses and emissions, for example, burning poly(vinyl chloride) (PVC) produces furans and dioxins [8]. In this context, green composites gain their importance.

Figure 1.1 shows a classification of biodegradable polymers mainly in two families. A large number of these biodegradable polymers (biopolymers) are commercially available. They show a large range of properties, and they can compete with nonbiodegradable polymers in different industrial fields (e.g., packaging).

FIGURE 1.1 Classification of biodegradable polymers in four families.

1.2 BIODEGRADABLE POLYMERS

1.2.1 Starch

Starch is a widely used bioplastic that is actually a storage polysaccharide in plants. It is composed of both linear and branched polysaccharides known as amylose and amylopectin, respectively. The ratio of these polysaccharides varies with their botanical origin, and generally, native starches contain around 85–70% amylopectin and 15–30% amylose. Starch softening temperature is higher than its degradation temperature due to the presence of many intermolecular hydrogen bonds [9], which affects its processing. Plasticizers like water, glycerol, and sorbitol will help in increasing the free volume and thereby decreasing the glass transition and softening temperatures [10]. The schematic showing the process of obtaining TPS is shown in Figure 1.2. Traditional extrusion, injection molding, and compression molding can be used to process thermoplastic starch. The melt processing technique of obtaining thermoplastic starch is a complex operation that involves plasticization, devolatilization, melt–melt mixing, and morphology control. The final morphology of TPS depends on composition, mixing time, temperature, shear, and elongation rate of the operation. Although it is possible to make useful products from TPS alone, extreme moisture sensitivity of starch leads to limited practical application. Therefore, the reality in commercialization of starch-based plastics involves blending of TPS with other polymers and additives. Thermoplastic starch formation [11] is shown in Figure 1.2.

FIGURE 1.2 Thermoplastic starch formation.

Source: Xie et al. [11], figure 37. Reproduced with permission from Elsevier. Copyright 2015.

1.2.2 Cellulose

Cellulose is an abundant and ubiquitous natural polymer. It is the major structural component of plant cells and is found throughout nature. It is widely used in industrial applications in different forms. Cellulose is mostly obtained from wood and cotton at present for many applications; on the other hand, cellulose pulp is also being extracted from agricultural by-products such as bagasse, stalks, and crop straws. Currently, cellulose-based materials are used in two forms on an industrial scale [12]:

- Regenerated cellulose is used for fiber and film production and cannot be melt processed.

- Cellulose esters are used in a broad array of applications including coatings, biomedical uses, and other usual plastic applications.

Nonplant resources can also be used to produce cellulose, especially bacteria and tunicates. There is a considerable interest in obtaining cellulose from bacteria, popularly known as bacterial cellulose. Acetobacter xylinum produces this cellulose under unique culturing conditions to form a fibrous network [13]. A. xylinum produces cellulose with good mechanical strength and biodegradability. “Nanocellulose” comprises of fibrous or crystalline units of cellulose between 5 and 500 nm in diameter with a length of several micrometers. Nanocellulose is available in two forms, that is, microfibrils and nanowhiskers [14].

1.2.3 Chitin and Chitosan

Interest in these polymers is driven by their unique properties such as renewable, biocompatible, biodegradable, and nontoxic with excellent adsorption properties [15]. Chitin is an abundantly available natural polysaccharide and is the supporting material in many invertebrate animals such as insects and crustaceans. The monomers in chitin are 2-acetamido-2-deoxy-_-D-glucoses, which are attached to (1→4) linkages, and this polymer degrades by chitinase. The deacetylated chitin is known as chitosan; this deacetylation is more than 50% [16]. Chitosan is a semicrystalline polymer, and its crystallinity depends on the extent of deacetylation [17]. Chitosan is receiving more attention as a possible polysaccharide resource for biomedical applications [17].

The process of obtaining chitin from the shells of crab or shrimp starts with the extraction of proteins followed by treatment with calcium carbonate for dissolution of shells. The chitin obtained from this process is then deacetylated with 40% sodium hydroxide for 1–3 h at 120°C. This yields a 70% deacetylated chitosan [18]. The molecular weight of chitosan depends on the source, and it varies from 100 to 1100 kDa [19]. Commercial chitosan has around 50–90% deacetylation degree [17]. Chitosan has been extensively explored for films and fibers [16]. Fibers from these polymers are very useful, as wound dressing materials and absorbable sutures [19, 20]. They have generated interest in biomedical applications [17].

1.2.4 Proteins

A protein is a random copolymer of different amino acids. Based on the origin, proteins can be classified as plant proteins (e.g., soy, pea, canola, and wheat) and animal proteins (e.g., gelatin, whey, casein, and keratin). Generally, proteinaceous biomaterial can be defined as a stable 3D polymeric network that is strengthened by hydrophobic interactions and hydrogen bonding [21]. Unfolding and realigning of the proteins are necessary to produce useful biomaterials. Hydrophilic compounds and lipid compounds are used for plasticization of proteins. Water, glycerols, fatty acids, and oils are commonly used plasticizers for proteins. Plasticizers reduce the interactions between functional units and improve the polymeric chain mobility and intermolecular spacing. This also results in reduction in glass transition temperature...

| Erscheint lt. Verlag | 16.2.2016 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Biologie ► Ökologie / Naturschutz |

| Naturwissenschaften ► Chemie | |

| Naturwissenschaften ► Geowissenschaften | |

| Technik ► Maschinenbau | |

| Schlagworte | Agriculture • Applications • biodegradable • Biologischer Abbau • Biorenewable Resources • Chemie • Chemistry • Composites • Conclusion • contributors xii • Fibers • Grüne Chemie • Green Composites • Grüne Chemie • Landwirtschaft • Materials Science • Materialwissenschaften • modification • Nachhaltige u. Grüne Chemie • Nachhaltige u. Grüne Chemie • Nachwachsende Rohstoffe • Nanocomposites • Nanofillers • Plasma • Processing • references surface • renewable • sreerag gopi • Sun • Sustainable Chemistry & Green Chemistry • Treatment • Verbundwerkstoffe |

| ISBN-10 | 1-118-91091-5 / 1118910915 |

| ISBN-13 | 978-1-118-91091-7 / 9781118910917 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich