Chemical Process Retrofitting and Revamping (eBook)

Some chapters in the book are contributed by practitioners whereas others are from academia. Hence, the book includes both new developments from research and also practical considerations. Many chapters include examples with realistic data. All these feature make the book useful to industrial engineers, researchers and students.

The proposed book will be divided into three parts. The chapters in Part I provide an overview of certain aspect of process retrofitting. The focus of Part II is on computational techniques for solving process retrofit problems. Finally, Part III addresses retrofit applications from diverse process industries. Some chapters in the book are contributed by practitioners whereas others are from academia. Hence, the book includes both new developments from research and also practical considerations. Many chapters include examples with realistic data. All these feature make the book useful to industrial engineers, researchers and students.

Gade Pandu Rangaiah, Department of Chemical & Biomolecular Engineering, National University of Singapore, Singapore.

1

Introduction

G.P. Rangaiah

Department of Chemical & Biomolecular Engineering, National University of Singapore, Singapore

1.1 Chemical Process Plants

There are a wide range of chemical process industries such as agrochemicals, ceramics, cement, cosmetics, fragrances and flavors, food and drinks, glass, industrial gases, industrial/inorganic chemicals, leather, mineral processing, nuclear, oil and gas, paper and pulp, paints and pigments, petrochemicals, pharmaceuticals, polymers, rubber, soap and detergent, specialty chemicals, synthetic fibers, sugar, vegetable oils and water. Many of these involve continuous processes whereas some are batch processes. New process plants continue to be designed and built, relatively more in developing countries, to produce useful and valuable products required by the society. These are usually designed and their economic viability assessed assuming a plant life of 10 to 20 years. However, chemical plants, once built, continue to operate for very much longer than this assumed plant life.

Thus, chemical process plants in operation have been increasing steadily in the world. They were designed in the past few years or even decades, perhaps optimally for the economic, technological and societal conditions at that time. Obviously, technological knowledge has been advancing since the existing plants were designed. In addition, economic and societal conditions are dynamic and change over time for one reason or other. For example, energy prices and global warming concerns have increased substantially; new and better technologies (such as catalysts, process equipment and their internals), separation processes and intensified processes as well as simulation and optimization techniques are being continually developed and improved through research and industrial implementation.

Hence, it is imperative to review regularly the performance of the existing plants and assess the possibilities for their improvement. This can be for one or more of the following objectives (Grossmann et al., 1987; Rong et al., 2000).

- To reduce energy required and/or operating cost

- To improve conversion and/or selectivity of reactions

- To increase production/throughput of the process

- To use feed of different quality and/or alternative feed

- To meet new specifications of product(s)

- To produce new products

- To enhance the control of the process

- To improve the safety, reliability and flexibility of the process

- To reduce the adverse impact of the process on the environment.

The first and relatively simple step is to optimize and set the operating conditions such as temperature, pressure and flow rate in the existing process for the chosen objective (for example, energy required and operating cost). This is often referred to as operation optimization, and involves analysis of the process and use of optimization techniques. In operation optimization, there is no change in process configuration or equipment. It can be performed off-line or on-line because of frequent changes in the operating environment of the process (such as product requirements and prices). On-line optimization is also known as real time optimization. Process improvement by operation optimization is limited because of constraints imposed by current process configuration, equipment and/or technology employed. It is thus necessary to consider modifications in all these for improving the current process substantially.

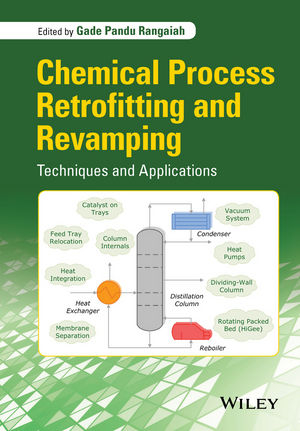

1.2 Process Retrofitting and Revamping

Process retrofitting and revamping refers to making suitable changes and/or additions to existing process configuration and equipment. It may involve new technology such as membrane separation or reactive distillation to supplement or replace distillation. One example of equipment and configuration changes in a process is heat exchanger network retrofitting, which involves area additions in existing exchangers and/or installation of new exchangers for increased energy recovery and re-use. Obviously, process retrofitting and revamping should maximize the use of the existing equipment in the plant as much as possible.

Analysis, simulation and optimization techniques could be used to achieve the chosen objective of process retrofitting/revamping. However, process retrofitting/revamping is more than operation optimization because the former considers changes to the process configuration and equipment in addition to operating conditions. Hence, solving a process retrofitting/revamping problem and implementing the solution found are more complex and challenging than those in the case of operation optimization.

Is there some difference between process retrofit and revamp? According to oxforddictionaries.com, revamp is to give a new and improved form, structure or appearance (to something), and retrofit is to provide (something) with a component or accessory not fitted during manufacture. Although these two meanings seem to be similar, process retrofit perhaps refers to adding new equipment to the existing process and so its scale, complexity and capital cost are relatively lower. On the other hand, process revamp involves changes in configuration and so its scale, complexity and capital cost are more. Currently, retrofit and revamp are often used synonymously in the chemical engineering literature although some practitioners use retrofit for smaller projects (that is, investment) and revamp for bigger projects.

In the technical literature, Rong et al. (2000) state that the main objectives of process retrofits include increasing the production capacity, efficiently processing new feedstock, utilizing new process technologies, reducing environmental impact, and reducing operating costs. According to Smith (2005), the motivation to retrofit (or revamp) an existing plant could be to increase capacity, allow for different feed or product specifications, reduce operating costs, improve safety and reduce environmental emissions. Kemp (2007), in the glossary of terms, defines retrofit or revamp as any change to an existing chemical process. On the other hand, Towler and Sinnott (2012) state that revamps fall into two categories: debottlenecking (discussed below) and retrofitting, which implies the former is not within the scope of retrofitting.

Should we distinguish retrofit/retrofitting and revamp/revamping? It is perhaps desirable for clarity and consistency. As suggested by Rao in Chapter 5, retrofitting can be used to mean adding to or replacing the whole or part of one type of equipment with a better alternative, and revamping for reorganizing the process involving several process steps (thus different equipment types). This indicates that retrofitting is smaller in scale, complexity and capital cost compared with revamping. Thus, the suggested distinction between retrofit and revamp is consistent with the use of these terms by some practitioners.

One of the purposes of process changes is to increase the plant throughput (that is, increasing production rate without any change in feed, process performance or product quality). This specific activity is referred to as debottlenecking. This common term in process industries is related to a bottle's neck, which is generally narrow and limits the flow rate through it. Obviously, the neck has to be widened for increasing the flow rate. Similarly, in debottlenecking of an operating process, equipment/operation limiting the throughput is identified and then it is suitably modified for increasing the production rate. In this way, process capacity can be increased by 5 to 20%, with much smaller capital investment compared with building new facilities. This is possible because of the spare size/capacity available in many items of the existing equipment because of design margins used at the time of their design and fabrication. It is possible to increase the throughput by modifying one (type of) equipment or several types of equipment. Thus, debottlenecking can be achieved by retrofit or revamp. In other words, one objective of retrofit or revamp can be debottlenecking. Recall that retrofit and revamp can be for any of the reasons listed in the previous section. For specificity and clarity, debottlenecking (and not retrofit or revamp) should be used if the sole objective of process changes is an increase in the plant throughput. Note it is different from plant expansion, wherein there are no existing items of equipment to be considered and generally no space restrictions.

How is process retrofit/revamp different from operation optimization? Unlike the operation optimization, retrofit/revamp design will have more degrees of freedom (that is, variables related to existing equipment changes and to new equipment) and more combinations to be considered for optimization. Hence, it is much more challenging than operation optimization. However, retrofit/revamp design can improve the process significantly compared with operation optimization.

Analysis and solution of a process retrofit/revamp problem will require simulation and optimization. Hence, computational techniques for process simulation and optimization find applications in process retrofit and revamp. However, appropriate models have to be developed for process retrofit/revamp, and the resulting optimization problems have more constraints and are more challenging than are operation optimization problems.

1.3 Stages in Process Retrofitting/Revamping Projects

There are five main stages in the industrial retrofit/revamp projects. These are: (1)...

| Erscheint lt. Verlag | 29.1.2016 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie ► Technische Chemie |

| Technik | |

| Schlagworte | Business & Management in Chemistry • chemical engineering • Chemie • Chemische Verfahrenstechnik • Chemistry • Computational Techniques • Debottlenecking • Nachhaltige u. Grüne Chemie • Nachhaltige u. Grüne Chemie • Optimization • Process Control • Process Engineering • Process Integration • Prozesssteuerung • Retrofitting • revamping • Separation processes • Simulation • Sustainable Chemistry & Green Chemistry • Wirtschaft • Wirtschaft u. Management in der Chemischen Industrie |

| ISBN-13 | 9781119016304 / 9781119016304 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich