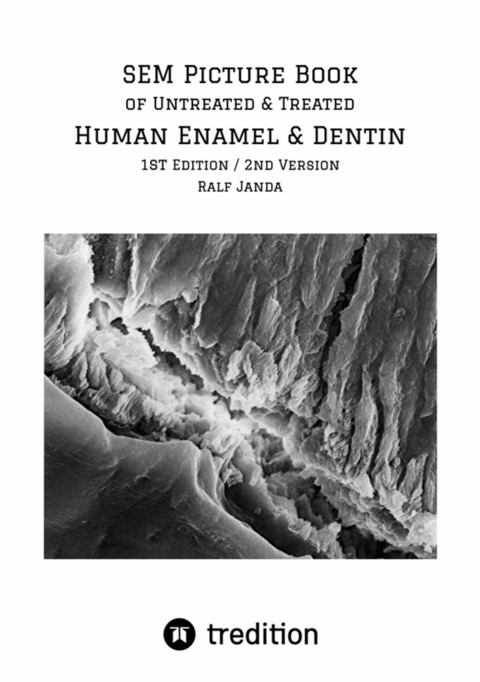

SEM Picture Book of Untreated & Treated Human Enamel & Dentin (eBook)

222 Seiten

tredition (Verlag)

978-3-347-35177-6 (ISBN)

Ralf Janda was born in 1953 in Berlin. He obtained his Abitur (secondary school-leaving examination in 1973 and pursued chemistry at the Free University Berlin (FUB) from 1973 to 1978, thereby obtaining the degree Diploma-Chemist (summa cum laude). While working as a scientific assistant and researcher at the FUB he wrote his doctoral thesis and graduated in 1979 as a natural science doctor, Dr. rer. nat. (summa cum laude). His professional career as a scientific assistant and lecturer at the FUB came to an end in 1980. Ralf Janda also joined the dental industry in this year as head of research and development. He worked for many internationally leading dental companies (Kulzer GmbH, Germany, Degussa AG-Dental Division, today Degudent/Dentsply GmbH, Germany, Dentsply/Detech GmbH, Germany, Dentsply INC., USA, Dentaurum GmbH & Co. KG, Germany) in different leading positions as head of: R&D, production, quality assurance, dental technology, worldwide project leader until 2003. During this time, he was a member of many dental standard commissions, and from 1987 to 2000, he was also a member of the drug commission A at the drug institute of the Federal Republic of Germany. In 2003, he joined the cosmetic industry specialized on light-curing artificial nail products and stayed there until 2017. In addition to his professional pursuits, Ralf Janda has maintained a lengthy and extensive scientific career as a researcher and lecturer at numerous universities, beginning at the FUB in 1978. From 1988 to 1990, he was a lecturer at the Faculty of Material Sciences of the Technical University Berlin, where he taught resin composite materials. From 1991 to 1999, he worked as a researcher and lecturer for non-metallic dental materials at the dental department of the Medical Faculty of the Johann Wolfgang Goethe-University, Frankfurt/M. In 1992, he obtained his Habilitation (qualification for a teaching career at universities) and the degree Privatdozent (associate professor) in dental material science at the same university. From 1999 to 2004, Ralf Janda was Privatdozent at the Center of Dental Medicine of the Medical Faculty, Charité, Humboldt-University Berlin. From 2004 to 2021 he worked as a researcher and lecturer at the dental clinic of the Medical Faculty of the Heinrich Heine University, Düsseldorf. In 2006, he was appointed as apl. Professor (adjunct professor) in dental material science. Since 2021 he put his focus on writing textbooks about dental materials.

Ralf Janda was born in 1953 in Berlin. He obtained his Abitur (secondary school-leaving examination in 1973 and pursued chemistry at the Free University Berlin (FUB) from 1973 to 1978, thereby obtaining the degree Diploma-Chemist (summa cum laude). While working as a scientific assistant and researcher at the FUB he wrote his doctoral thesis and graduated in 1979 as a natural science doctor, Dr. rer. nat. (summa cum laude). His professional career as a scientific assistant and lecturer at the FUB came to an end in 1980. Ralf Janda also joined the dental industry in this year as head of research and development. He worked for many internationally leading dental companies (Kulzer GmbH, Germany, Degussa AG-Dental Division, today Degudent/Dentsply GmbH, Germany, Dentsply/Detech GmbH, Germany, Dentsply INC., USA, Dentaurum GmbH & Co. KG, Germany) in different leading positions as head of: R&D, production, quality assurance, dental technology, worldwide project leader until 2003. During this time, he was a member of many dental standard commissions, and from 1987 to 2000, he was also a member of the drug commission A at the drug institute of the Federal Republic of Germany. In 2003, he joined the cosmetic industry specialized on light-curing artificial nail products and stayed there until 2017. In addition to his professional pursuits, Ralf Janda has maintained a lengthy and extensive scientific career as a researcher and lecturer at numerous universities, beginning at the FUB in 1978. From 1988 to 1990, he was a lecturer at the Faculty of Material Sciences of the Technical University Berlin, where he taught resin composite materials. From 1991 to 1999, he worked as a researcher and lecturer for non-metallic dental materials at the dental department of the Medical Faculty of the Johann Wolfgang Goethe-University, Frankfurt/M. In 1992, he obtained his Habilitation (qualification for a teaching career at universities) and the degree Privatdozent (associate professor) in dental material science at the same university. From 1999 to 2004, Ralf Janda was Privatdozent at the Center of Dental Medicine of the Medical Faculty, Charité, Humboldt-University Berlin. From 2004 to 2021 he worked as a researcher and lecturer at the dental clinic of the Medical Faculty of the Heinrich Heine University, Düsseldorf. In 2006, he was appointed as apl. Professor (adjunct professor) in dental material science. Since 2021 he put his focus on writing textbooks about dental materials.

Preparation of the Specimens

1 Design

The specimen designs were made as described in the following paragraphs.

Design type 1 (DesTyp-1): Vertical and horizontal saw-cuts were made in molar teeth, resulting in a step-like design (Fig. 1). Therefore, it was possible to observe the parallel and perpendicular course of enamel prisms and dentin tubules. Since only one half of the tooth specimen was treated, it was possible to investigate the same area untreated and treated.

Fig. 1: Design type 1 (step-like design).

Design type 2 (DesTyp-2): Vertical and horizontal saw-cuts were made in molar teeth resulting in a step-like design followed by a fracture process from cervical to occlusal along the tooth axis done with a strong and sharp knife (Fig. 2). The knife was placed cervically in order not to damage the occlusal surface. In the first case, the center of the step- like sawn tooth specimen was treated before the fracture process so that treated sawing areas adjacent to untreated fracture areas could be investigated. In the second case, the fracture area of the second half of the fractured tooth specimen was treated so that it was possible to investigate treated sawing areas adjacent to treated fracture areas.

Fig. 2: Design type 2 (step-like design followed by a fracture process).

Design type 3 (DesTyp-3): Discs of 2 to 3 mm thickness perpendicular to the tooth axis were prepared from molar teeth by sawing.

Designs for chemical treatment (DesTyp-3a)

To prepare the specimens for PicSer-11 to 19b, the discs were fractured into two halves using a very sharp knife. Each of the two halves was treated by completely immersing in the respective treatment medium and then SEM-investigated.

Designs for replica technique (DesTyp-3b)

The disk specimens for PicSer-21a to 22b were differently treated as described in chapter “Replica Technique”.

Design type 4 (DesTyp-4): Incisors were sectioned by a horizontal saw, cut into two halves.

2 Mechanical Treatment

The molar teeth of DesTyp-1 and DesTyp-2 were mounted on MMA/PMMA resin (Technovit 4004, Kulzer GmbH, Wehrheim, Germany) so that none of the investigated areas was touched with the resin. Before the SEM investigation, the resin base was cut off.

The teeth of DesTyp-3 and DesTyp-4 were totally embedded in the aforesaid resin. Sawing of all specimens was done with a diamond low speed saw under rinsing with water (Isomet Low Speed Saw, Bühler-Met GmbH, Esslingen, Germany). After sawing, all sawing areas were polished to high gloss under rinsing with water on a cotton cloth using highly dispersed aluminum oxide (max. particle size 0.05 µm, Bühler-Met GmbH) on a rotating plane disc (Ecomet III, Bühler-Met GmbH).

After sawing and polishing, the specimens were spotless with dist. water for 5 min in an ultrasonic bath to remove all residues of the polishing medium.

Before ultrasound cleaning energy dispersive X-ray analysis founds Al-signals deriving from the aluminum oxide polishing medium, what was not the case afterward anymore. SEM investigations did not show aluminum oxide particles on the tooth surfaces, and the tubules were not smeared up. However, very seldom some few residues of the polishing and embedding material were found in the tubule openings (see PicSer-1).

2 Chemical Treatment

Regarding DesTyp-1, DesTyp-2 and DesTyp-3b, the treatment medium was applied with a little brush. In case that only one part of the specimen was treated, the treatment was done cautiously so that all the other parts remained untouched.

Regarding DesTyp-3a, the fractured specimen was treated by totally immersing in the treatment medium.

The following chemical treatments were done:

Chemical treatment 1 (ChemTreat-1): Treatment of the specimen with 35 mass% aqueous ortho-phosphoric acid (Sigma-Aldrich Chemie GmbH, Taufkirchen Germany) for 3 min. Then rinsing with dist. water for 1 min, followed by different dehydration/drying methods. Finally, gold sputtering was done. The different design types were treated as follows:

a) DesTyp-1: Half-side treatment of the specimen’s sawing areas.

b) DesTyp-2: Half-side treatment of the specimen’s sawing areas and the middle part of the outside enamel surface, but the fracture area remained untreated.

c) DesTyp-2: Half-side treatment of the specimen’s sawing areas, the middle part of the outside enamel surface and only partial treatment of the dentin fracture area (horizontal dentin fracture area).

d) DesTyp-3b: Half-side treatment of the specimen’s sawing and fracture areas (see T-Rep-3).

Chemical treatment 2 (ChemTreat-2): Complete treatment of the DesTyp-3a fragment with 35 mass% aqueous ortho-phosphoric acid (Sigma-Aldrich Chemie GmbH) for 30 min. Then rinsing with dist. water for 5 min, followed by dehydration/drying and gold sputtering.

Chemical treatment 3 (ChemTreat-3): Complete treatment of the DesTyp-3a fragment with 1.2 mol aqueous sodium hydroxide (Sigma-Aldrich Chemie GmbH) (pH 13.5) for 60 min. Then rinsing with dist. water for 5 min, followed by dehydration/drying and gold sputtering.

Chemical treatment 4 (ChemTreat-4): Complete treatment of the DesTyp-3a fragment with an aqueous solution of 0.5 mol of the disodium salt of EDTA (ethylene diamine tetraacetic acid, Sigma-Aldrich Chemie GmbH) adjusted with 1 mol aqueous sodium hydroxide to pH 13.1 for 3 min. Then rinsing with dist. water for 3 min, followed by dehydration/drying and gold sputtering. At high pH values, the disodium salt of EDTA provides its optimal complexing effect.

Chemical treatment 5 (ChemTreat-5): Complete treatment of the DesTyp-3a fragment with an aqueous solution of 0.5 mol of the disodium salt of EDTA (ethylene diamine tetraacetic acid, Sigma-Aldrich Chemie GmbH) adjusted with 1 mol aqueous sodium hydroxide to pH 13.1 for 60 min. Then rinsing with dist. water for 5 min, followed by dehydration/drying and gold sputtering. At high pH values, the disodium salt of EDTA provides its optimal complexing effect.

Chemical treatment 6 (ChemTreat-6): Complete treatment of the DesTyp-3a fragment with an aqueous solution of 10 mass% polyacrylic acid (Degapas 8105S, batch-no TPR 186, Degussa AG, Hanau, Germany) with pH 2.0 for 3 min. Then rinsing with dist. water for 1 min, followed by dehydration/drying and gold sputtering.

Chemical Treatment-7 (ChemTreat-7): Complete treatment of the DesTyp-3a fragment with an aqueous solution of 10 mass% polyacrylic acid (Degapas 8105S, batch-no TPR 186) with pH 2.0 for 60 min. Then rinsing with dist. water for 1 min, followed by dehydration/drying and gold sputtering.

Chemical treatment-8 (ChemTreat-8): Complete treatment of the DesTyp-3a fragment with an aqueous solution of 10 mass% polyacrylic acid (Degapas 8105S, batch-no TPR 186) adjusted with 1 mol aqueous sodium hydroxide to pH 13.3 for 60 min. Then rinsing with dist. water for 5 min, followed by dehydration/drying and gold sputtering.

Chemical treatment 9 (ChemTreat-9): Complete treatment of the DesTyp-3a fragment with undiluted bis(methacryloyloxyethyl) hydrogen phosphate (P-acid-ester, laboratory product) for 3 min. Then rinsing with dist. water for 1 min, followed by dehydration/drying and gold sputtering. Such phosphate compounds were and are still used as adhesion promoters in enamel/dentin adhesives [5, 6].

Chemical treatment 10 (ChemTreat-10): Complete treatment of the DesTyp-3a fragment with an emulsion of equal parts P-acid-ester and dist. water (obtained pH 0.9) for 3 min. Then rinsing with dist. water for 1 min, followed by dehydration/drying and gold sputtering. This was done to investigate if demineralization is stronger in aqueous surrounding.

Chemical treatment 11 (ChemTreat-11): Complete treatment of the DesTyp-3a fragment with a 1:1 mixture of undiluted P-acid-ester and tetra(methacryloyloxyethyl) pyrophosphate (Pyro-ester, laboratory product) for 3 min. Then rinsing with dist. water for 1 min, followed by dehydration/drying and gold sputtering. Such phosphate compounds were used as adhesion promoters in enamel/dentin adhesives [5].

Chemical treatment 12 (ChemTreat-12): Complete treatment of the DesTyp-3a fragment with an emulsion of equal parts of the 1:1 mixture of P-acid-ester and Pyro-ester (obtained pH 1.4) for 3 min. Then rinsing with dist. water for 1 min, followed by dehydration/drying and gold sputtering. This was done to investigate if demineralization is stronger in aqueous surrounding.

Fig. 3: Structural formula of bis tetra(methacryloyloxyethyl) pyrophosphate) hydrogen phosphate (P- acid-ester).

Fig. 4: Structural formula of...

| Erscheint lt. Verlag | 1.7.2021 |

|---|---|

| Verlagsort | Ahrensburg |

| Sprache | englisch |

| Themenwelt | Medizin / Pharmazie ► Zahnmedizin |

| Schlagworte | conditioning dentin • conditioning enamel • Dental • Dentin • dentin fracture • dentin picture • dentistry • Enamel • enamel fracture • enamel picture • etching dentin • etching enamel • human dentin • human enamel • human enamel and dentin • scanning electron microscope • scanning electron microscopic picture • scanning electron microscopic pictures of dentin • scanning electron microscopic pictures of enamel • SEM • sem picture • sem pictures of dentin • sem pictures of enamel • structure dentin • structure enamel • treatment dentin • treatment enamel |

| ISBN-10 | 3-347-35177-0 / 3347351770 |

| ISBN-13 | 978-3-347-35177-6 / 9783347351776 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

DRM: Digitales Wasserzeichen

Dieses eBook enthält ein digitales Wasserzeichen und ist damit für Sie personalisiert. Bei einer missbräuchlichen Weitergabe des eBooks an Dritte ist eine Rückverfolgung an die Quelle möglich.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich