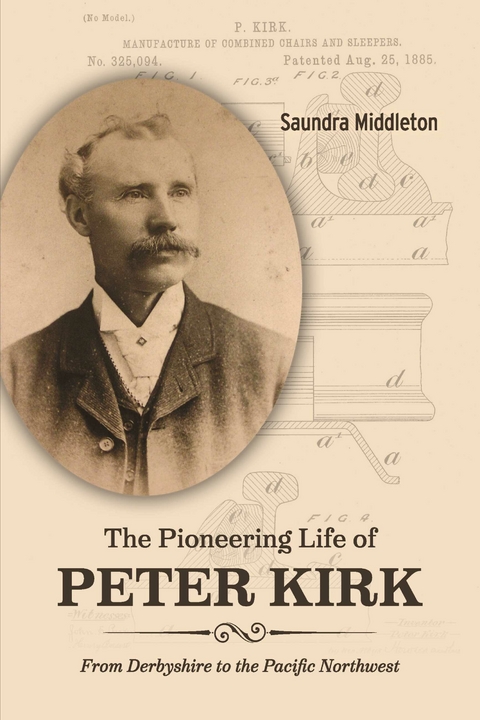

Pioneering Life of Peter Kirk (eBook)

318 Seiten

Bookbaby (Verlag)

978-1-0983-7092-3 (ISBN)

Some might describe Peter Kirk's story as one of riches to rags, but it is more like, top hat and tails to smart casual. This biography begins with a short introduction to the English iron mogul and how he arrived in Seattle, Washington Territory in 1886. It explains his family's 100-year history in the iron industry, riding the wave of success during the Industrial Revolution through Britain's successful Victorian era rail expansion. Transferring that legacy down the generations did not always go smoothly. Family curses, rivalries, and a propensity for those named "e;Peter"e; to leave the security of the family business catapulted Peter out of the Derbyshire (county) valley where his Kirk family had lived for 600 years. The story follows his early business successes in Workington (Cumbria county), often facilitated by Peter Kirk's inventions in creating efficiency in the iron-producing process and new products in a competitive market. Britain's status as the world's top iron producer was giving way to America's burgeoning growth. Kirk had to branch out in the New World to keep his ironworks solvent and his 1000 employees working. He traveled to the American continent on a fact-finding mission and discovered Washington Territory had resources and opportunity to build a new steel works. Confronted with hurdles like land laws prejudiced against immigrants, demanding mining companies, railroad and frontier town competition, insufficient cash flow, and the worst recession in American history, Kirk struggled to accomplish his greatest dream. However, he did not give up on Kirkland, the little town he carved out of the Pacific Northwest forests. Away from the engineer's desk and out of the boardroom, Kirk was an accomplished musician and devoted family man. Unusual for the Victorian era, his wife, Mary Ann, partnered with him in some of his business dealings. But troubles hit on the family front as well. Children died prematurely; scandal threatened his family's status; Mary Ann returned to England. This book is a journey of generations, across continents, through life's upheavals, celebrating successes, and adjusting to changing times and cultures.

One—The Kirk Blacksmiths of Chapel-en-le-Frith

“The Chapel-en-le-Frith Ironworks is one of the oldest iron works in the Midlands being founded by the Kirk family probably round about the year 1770. The Forge and Rolling Mills…were formerly famous for their brand of Kirk best hammered scrap merchants bar iron and forgings, which found ready markets in all parts of the world.”1

Mr. Chaloner, 1943

Peter Kirk’s birthplace, Chapel-en-le-Frith, in the heart of Derbyshire county in England, was a small, unobtrusive village lodged in the middle of the Peak Forest. Derbyshire is a landlocked county more than 150 miles northwest of London. Craggy and bare hilltops enclosed the hamlet’s rolling hills, once described by a local scholar as “clothed with stunted oaks and underwood, and their bases surrounded by treacherous bogs and reedy pools.”2

In ancient times, the Peak Forest was set aside to protect game for the hunting pleasure of the King and his nobles.

The red deer browsed in great numbers through the sunny glades. The wild boar sharpened his tusks against the rugged bark of the forest trees: whilst from their mountain fastnesses the hungry wolves came howling in search of prey. The wild cat prowled with stealthy tread through the heather, waiting for the chattering grouse or timid hare, and the shriek of the golden eagle was heard from the dark heights of Kinder [mountain]. In the stagnant pools the otter sank with a sullen plunge, frightening the wild ducks from their home amongst the reedy banks.3

The King was more apt to pay his foresters, verderers, and sheriffs in land than money, coin being scarce in the 11th and 12th centuries. Eventually, the foresters and keepers became so numerous that in 1220, they bought land on a small knoll to build a chapel. They called the place Chapel-en-le-Frith (chapel in the forest) and named their church St. Thomas Beckett.

Cobblestone streets descended from the churchyard and meandered through the village and into the valley, a reminder that many local and ancient bloodlines did the same. In those early times, when the population was small, townsfolk did not use last names. As the population grew, common first names often needed a descriptor to help distinguish one Henry, Thomas, or William from another. Place names and occupations were widely used. Local historians believe the name Kirk (and its variants) came from the Norse for church, kirkja, meaning “dweller by the church.”4 Certainly in the case of Peter Kirk’s known ancestors, this proved true, as they lived, farmed, and later worked the iron forge near St. Thomas Beckett Church.

1770 Blacksmith Brothers

Over the centuries, the king relinquished more land and rights to his subjects. The legends of Robin Hood gave way to farming concerns. Mineral resources of iron ore, coal, lead, and limestone enriched the economy of the area. Residents had long developed transportation systems that moved these valuable raw materials to markets. Chapel-en-le-Frith stood at a crossroads, as did the Kirk iron works. The earliest known forebears of the Kirk ironworks included Victorian Peter’s great-grandfather, Thomas Kirk Jr., and his older brother Peter, here nicknamed, “Peter the Elder.” These brothers were born about 1750 and 1748, respectively.5 Both lived in Townend, on the edge of Chapel-en-le-Frith. These two men are the “1770 Blacksmith Brothers.”

Lack of records prevents discovery of how the Blacksmith Brothers came into the iron business. In fact, much of 18th century Kirk history remains shrouded due to an absence of suitable sources. The accepted start of the business in 1770 was derived from modern sources passed down from earlier common knowledge.6 As young men, ages eighteen and twenty, Thomas and Peter likely had help from their father in establishing the foundry.

Parish records of marriages and baptisms often listed the brothers’ occupations as blacksmiths.7 This indicated they had a smithy where they worked with iron, but there remains the question of whether they produced iron or metal items from pre-casted or pre-forged pig iron. Nor is it clear how large an operation they had.

The ability to work with metal was a boon as the Industrial Revolution took hold. By 1770, the young Blacksmith Brothers had already witnessed improvements to industry mechanizations. When they were teenagers, the spinning jenny revolutionized the textile industry by automating the weaving of cloth. A year before they established their ironworks, James Watts of Scotland added a condenser to the existing steam engine and produced a machine with improved power and greater efficiency than the original. Industries rapidly embraced these new technologies, making them key components in the Industrial Revolution.

This era coincided with replacing wood with iron for machines and tools. For decades to come, Britain’s pig iron production doubled every ten years.8 The Kirk enterprise benefited from this factory-launching, machine-building, tool-making boom. Any business capable of turning iron ore into metal to cast or shape into the plethora of metal parts needed for new factories found a ready market.

The Blacksmith Brothers also benefited from their strategic location. Chapel-en-le-Frith was less than 20 miles southeast of Manchester on a major road connecting it with other cities, including London. Manchester’s population during the Blacksmith Brothers’ era quadrupled as it became the first industrialized city in the world. The early Kirk ironworks also profited from the 15-mile Peak Forest Canal linking Manchester to Chapel-en-le-Frith. The canal project, coupled with the Peak Forest tramway, connected the coal and limestone quarries to manufacturing towns. The Kirk foundry had easy access to these new Industrial Revolution systems and the raw materials needed for iron manufacturing.

Producing iron was a hot, labor-intensive job. To make one ton of pig iron, a foundry needed approximately two tons of iron ore, one ton of coke, and half a ton of limestone. The 1770 Blacksmith Brothers hauled in wagonloads of iron ores such as hematite and magnetite, then heated them to high temperatures in their furnaces, reducing the ore to molten rock. Iron producers used limestone as a flux to remove impurities in the ore. Chemical reactions decomposed the limestone to calcium oxide, also known as quicklime. This combined with any siliceous minerals in the ore to form slag, which separated from the molten iron and floated to the top. Workers channeled the liquid ore to a sand bed designed with multiple outlets (resembling a pig). These outlets collected the molten iron to mold into pig iron ingots.

The ingots still contained impurities, which caused brittleness, but not enough to prevent shaping them into cast iron products. The Kirk forge produced wrought iron by reheating and hammering out these additional impurities. This process produced a stronger, more malleable material than cast iron. Manufacturers shaped the wrought iron into any form they chose, including the large rolled-out sheets used for shipbuilding and the small rivets used to attach them.

Methods for iron production also improved during the Industrial Revolution. Invented in 1784, a new process called puddling facilitated the smelting of pig iron in a blast furnace. Men stirred the liquefied iron with long metal rods that further oxidized the carbon as the rods melted into molten ore, increasing the purity of the iron. Family historian Geoffrey Peter Kirk described purification as, “White hot, pasty lumps of iron [which] emerged, like a dumpling in a gravy of molten impurities.”9 The puddler and his assistant extracted these lumps, or “puddles,” with large tongs. An experienced team could produce puddles at a rate of almost 300 pounds per hour. The puddles underwent further development in hammering and rolling mills. Puddling streamlined the entire process, enabling the mass production of wrought iron for the first time. However, it required strenuous labor and a high degree of skill in knowing when to pluck the puddles from the molten pool.

In April 1794, the older Blacksmith Brother, Peter the Elder, signed a 42-year lease for a piece of land in Townend, near the tramway and canal system, with plans of erecting a forge and waterwheel.10 It is possible the Kirk enterprise intended to expand their original business and take advantage of the boom in the iron trades and the new puddling technology. Perhaps they intended to install a drop hammer in use at the time. Waterwheels powered drop hammers by pumping water through pipes, operating a ram connected to the hammer. This action raised and lowered the hammer repeatedly, striking a piece of hot metal to pound out the impurities, resulting in wrought iron. This automated process allowed for greater production by greatly reducing the manual labor of pounding the metal.

For decades, the 1770 Blacksmith Brothers thrived in their business, but mortality caught up with them. In April 1811, approaching life’s end and without a child of his own, Peter the Elder passed his estate to his wife, his brother, and his brother’s children. The inheritance included...

| Erscheint lt. Verlag | 4.8.2021 |

|---|---|

| Sprache | englisch |

| Themenwelt | Literatur ► Biografien / Erfahrungsberichte |

| ISBN-10 | 1-0983-7092-9 / 1098370929 |

| ISBN-13 | 978-1-0983-7092-3 / 9781098370923 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Größe: 4,9 MB

Digital Rights Management: ohne DRM

Dieses eBook enthält kein DRM oder Kopierschutz. Eine Weitergabe an Dritte ist jedoch rechtlich nicht zulässig, weil Sie beim Kauf nur die Rechte an der persönlichen Nutzung erwerben.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich