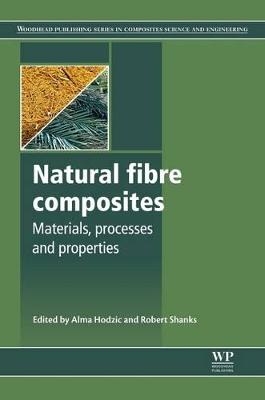

Natural Fibre Composites

Woodhead Publishing Ltd (Verlag)

978-0-08-101358-8 (ISBN)

- Titel wird leider nicht erscheinen

- Artikel merken

Chapters in part one introduce and explore the structure, properties, processing, and applications of natural fibre reinforcements, including those made from wood and cellulosic fibres. Part two describes and illustrates the processing of natural fibre composites. Chapters discuss ethical practices in the processing of green composites, manufacturing methods and compression and injection molding techniques for natural fibre composites, and thermoset matrix natural fibre-reinforced composites. Part three highlights and interprets the testing and properties of natural fibre composites including, non-destructive and high strain rate testing. The performance of natural fibre composites is examined under dynamic loading, the response of natural fibre composites to impact damage is appraised, and the response of natural fibre composites in a marine environment is assessed.

Natural Fibre Composites is a technical guide for professionals requiring an understanding of natural fibre composite materials. It offers reviews, applications and evaluations of the subject for researchers and engineers.

Alma Hodzic is Professor of Advanced Materials Technologies and Research Director of Advanced Manufacturing Institute at The University of Sheffield, UK. Robert Shanks is Emeritus Professor of Polymer Science, School of Applied Sciences, RMIT University, Melbourne, Australia.

Contributor contact details

Woodhead Publishing Series in Composites Science and Engineering

Part I: Natural fibre reinforcements

Chapter 1: Wood fibres as reinforcements in natural fibre composites: structure, properties, processing and applications

Abstract:

1.1 Introduction

1.2 Wood fibres: nature and behaviour

1.3 Modification of wood fibres for composites

1.4 Matrices (binders) of wood fibre composites

1.5 Process techniques of wood fibre composites

1.6 Properties of wood fibre composites

1.7 Applications of wood fibre composites

1.8 Future trends

Chapter 2: Chemistry and structure of cellulosic fibres as reinforcements in natural fibre composites

Abstract:

2.1 Introduction

2.2 Glucose monomer

2.3 Glucose biopolymerization

2.4 Cellulose structure

2.5 Chemical and solubility properties of cellulose

2.6 Sources of cellulose

2.7 Separation of cellulose

2.8 Purification of cellulose

2.9 Cellulose polymorphism

2.10 Chemical modification of cellulose

2.11 Preparation of nano-cellulose

2.12 Processing of cellulose

2.13 Applications of cellulose fibres

2.14 Conclusions

2.16 Appendix: abbreviations

Chapter 3: Creating hierarchical structures in cellulosic fibre reinforced polymer composites for advanced performance

Abstract:

3.1 Introduction

3.2 Creating hierarchical structures in (ligno)cellulosic fibre reinforced composite materials

3.3 Surface microfibrillation of (ligno)cellulosic fibres

3.4 Creating hierarchical structures in renewable composites by incorporating microfibrillated cellulose (MFC) into the matrix

3.5 Coating of (ligno)cellulosic fibres with bacterial cellulose

3.6 Conclusions and future trends

3.7 Acknowledgements

Chapter 4: Recycled polymers in natural fibre-reinforced polymer composites

Abstract:

4.1 Introduction

4.2 Fibre reinforcements in recycled composites

4.3 Processes for adding natural fibre reinforcements to composites

4.4 Improving the mechanical properties of recycled composites using natural fibre reinforcements

4.5 Applications of recycled polymer composites with natural fibre reinforcements

4.6 Conclusions and future trends

4.8 Appendix: abbreviations

Chapter 5: Electrospun cellulosic fibre-reinforced composite materials

Abstract:

5.1 Introduction

5.2 Electrospinning of non-derivatised and derivatised cellulosic fibres

5.3 Electrospun cellulosic fibres via polymer blends

5.4 Electrospun nanocomposite fibres

5.5 Mechanical properties of electrospun fibres and mats

5.6 Cellulose nanofibre-reinforced polymer composites

5.7 Future trends

Part II: Processing of natural fibre composites

Chapter 6: Ethical practices in the processing of green composites

Abstract:

6.1 Introduction

6.2 Social impact and ethical practice

6.3 Case study: Waste for Life waste management model

6.4 Conclusions

Chapter 7: Manufacturing methods for natural fibre composites

Abstract:

7.1 Introduction

7.2 Fibre reinforcements

7.3 Reinforcement forms

7.4 Bio-based polymer matrices

7.5 Composites manufacturing processes

7.6 Key parameters for successful processing of natural fibre composites

7.7 Manufacturing techniques for natural fibre-reinforced polymer matrix composites

7.8 Case studies: automotive, building and construction, and marine applications

7.9 Conclusions

Chapter 8: Compression and injection molding techniques for natural fiber composites

Abstract:

8.1 Introduction

8.2 Emerging compression and injection molding technologies in the production of natural fiber composites

8.3 Processing natural fiber composites at high temperatures

8.4 Conclusions

Chapter 9: Thermoset matrix natural fibre-reinforced composites

Abstract:

9.1 Introduction

9.2 Natural fibres used in thermoset matrix composites

9.3 Thermoset matrix types

9.4 Fabrication of thermoset matrix composites

9.5 Mechanical properties of synthetic resin composites

9.6 Bioderived resin composites

9.7 Applications of thermoset matrix natural fibre composites

9.8 Future trends

Part III: Testing and properties

Chapter 10: Non-destructive testing (NDT) of natural fibre composites: acoustic emission technique

Abstract:

10.1 Introduction

10.2 Using the acoustic emission (AE) technique in practice

10.3 Assessing results

10.4 Applications of AE

10.5 Future trends

10.6 Conclusions

10.7 Sources of further information and advice

Chapter 11: High strain rate testing of natural fiber composites

Abstract:

11.1 Introduction

11.2 Materials

11.3 Test methods

11.4 Results and discussion

11.5 Applications and future trends

11.6 Acknowledgments

Chapter 12: Performance of natural fiber composites under dynamic loading

Abstract:

12.1 Introduction

12.2 Natural fibers and natural fiber composites

12.3 Dynamic properties of natural fiber composites

12.4 Dynamic mechanical testing of natural fiber composites

12.5 Testing in practice: the example of pultruded natural fiber reinforced composites

12.6 Dynamic testing of composites

12.7 Performance of natural fiber reinforced composites under dynamic loading

12.8 Future trends

12.9 Acknowledgments

Chapter 13: The response of natural fibre composites to impact damage: a case study

Abstract:

13.1 Introduction

13.2 Mechanical characterization

13.3 Specimen preparation

13.4 Charpy impact test

13.5 Experimental results

13.6 Conclusion

Chapter 14: Natural fibre composites in a marine environment

Abstract:

14.1 Introduction

14.2 Properties and environmental impact of natural versus synthetic fibres

14.3 Natural fibre composites (NFCs) and moisture uptake

14.4 Geometrical considerations for plant fibres in NFCs

14.5 Marine applications of plant fibre composites

14.6 Conclusions and future trends

14.7 Sources of further information and advice

Index

| Erscheinungsdatum | 15.07.2016 |

|---|---|

| Reihe/Serie | Woodhead Publishing Series in Composites Science and Engineering |

| Verlagsort | Cambridge |

| Sprache | englisch |

| Maße | 156 x 234 mm |

| Themenwelt | Kunst / Musik / Theater ► Design / Innenarchitektur / Mode |

| Technik ► Maschinenbau | |

| Weitere Fachgebiete ► Land- / Forstwirtschaft / Fischerei | |

| ISBN-10 | 0-08-101358-2 / 0081013582 |

| ISBN-13 | 978-0-08-101358-8 / 9780081013588 |

| Zustand | Neuware |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich