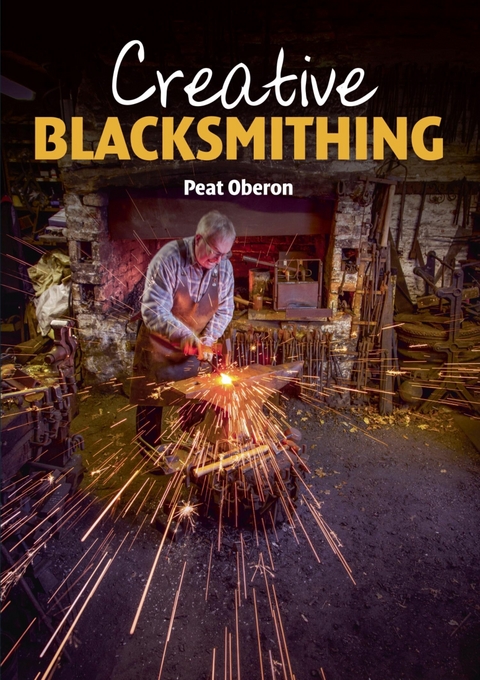

Creative Blacksmithing (eBook)

112 Seiten

Crowood (Verlag)

978-1-78500-034-8 (ISBN)

Peat Oberon is an artist blacksmith, who specializes in architectural, sculptural and decorative ironwork. He founded his own school of blacksmithing in the 1990s, and now combines his skills as an artist, craftsman and teacher with his life-long passion for working with metal.

CHAPTER TWO

BASIC TECHNIQUES

Drawing down

Drawing down is the blacksmith’s term for tapering, or reducing the size of material. Assuming now that you have got an anvil, a fire and a hammer, it is time to do some work.

A good preliminary exercise to practise both drawing down and bending is to make a rat tail handle. This is a task that involves drawing down the end of some 12 round steel along a distance of 150.

Rat tail handle.

Cold practice

Take a 700 length of steel, making sure that the ends have any burrs removed. Take hold of the bar about a third of the way along. Stand about 300 away from the anvil, place the end of the bar at the far side of the anvil, and press the left hand, holding the steel, against the left leg, which is your ‘third hand’, keeping the steel steady on the anvil. Raise the left hand so that the bar is lifted, making the far end slope at about 15 degrees to the anvil. Holding the hammer at the end – do not ‘choke’ the hammer – raise the right hand until the hammer face is about 15 degrees to the bar. This makes the hammer 30 degrees to the anvil. That will be the shape of the taper.

BURRS HURT

Safe working practices should be used always. Burrs on steel can cut hands.

Into the fire

Now, having tried all this cold, put the metal into the fire.

As a beginner, take a small hammer. You can do a lot of work with a small hammer. If you try to use a hammer that is too heavy, your arms will ache, and you can do permanent damage if you are not careful. Build up your strength gradually.

COLOUR CHECK

Until you have done quite a lot of practical forge-work, make a habit of drawing the metal out of the fire quite frequently, say, every thirty seconds, to check the colour. This is a necessary precaution. It is very easy to overheat the metal, and burn it beyond redemption.

Starting the taper with a blunt point; body about 300 from anvil, left hand pressed against left thigh; steel bar at 15 degrees to anvil, hammer at 15 degrees to metal, making point 30 degrees. The taper is 25 long with rounded end about 3 wide.

When the metal has reached orange, place it on the far side of the anvil, just away from the edge, not overhanging. With the hammer at 30 degrees and the bar at 15 degrees, using mostly the wrist, hit the end of the bar four times. Turn it through a quarter turn quickly, and hit it again four times. Always draw down with the metal square. Keep hitting until the metal has turned maroon, and return to the fire. When the end of the bar is down to 3, stop. The taper should now be about 25 long.

Now is the time to elongate the taper. When the metal is orange hot again, place the bar on the beak with about 85 overhanging. Using all parts of the arm, hit the metal as hard as you can, drawing the metal every blow about 6 towards yourself. When you reach the end, turn again a quarter and repeat the procedure. After a couple of heats, the hitting will not need to be done at the part nearest you, so that a long taper will be achieved. Due to the use of the beak, the surface of the taper will be uneven, but that does not matter.

The next part takes place on the face of the anvil. Take another heat, and place the taper on the anvil. Hammer it until flat on all faces.

Hammer marks

If you find that the hammer is leaving marks all over the work, you are not holding the hammer at the right position. The height of the right hand needs to be such that the face of the hammer is flat on the work when it hits. Try to make the surface finish as smooth as possible.

Continuing the taper. 85 over the beak, using all of arm to move hammer, spreading the metal lengthways.

ANVIL MARKS

It is important to realize that in all of this hammering, the anvil makes marks on the underside when you hit the upper side. Not quite as prominent, but nevertheless significant.

Rounding off

To make the square section round, we need to take off the corners to make an octagon section. This should be carried out at orange heat. Take note that the thinner the material, the quicker it will heat up. This is where control of the valve on the fire is important. Also, the position of the metal in the fire determines how much heating it gets. The temperature gradient from the middle of the fire to the outside is very steep.

Next, at a lower temperature (maroon colour – you will not see the corners if it is orange) take off the corners of the octagon to make a hexa-decagon (16 sides). That is near enough to round, unless there are prominent projections which can be hit. When all of this is done, heat the end, draw it down square to 1.5, and round it off. It is important to make the end of the taper really fine, or it will look lumpy when finished.

THE ADDED VALUE OF TEXTURE

In former years, ‘round’ section meant round, and great lengths were taken to achieve this, in a smooth finish. Nowadays, we have ‘texture’ where the marks (facets) of manufacture contribute a pleasing finish to the work.

Bending

Making the ring and wrapping the tail

Now we come to make the ring for the handle, giving practice in bending.

Centre punch hole, glowing brightly while surface of bar oxidizes to grey.

The inside diameter is about 35, so the length is about 150. At that distance from the start of the taper, mark the position of the start of the ring with a centre punch. Make a hole about 3 across. This will be seen when the metal comes out of the fire. The surface of the metal oxidizes to a grey scale when it cools, but inside the punch hole it will not oxidize.

Before placing the metal in the fire, bend it slightly towards the punched hole. This will not only show where to look for the hole, but it will dip nicely into the fire at the right point. After heating, slap the metal on the anvil to straighten it, and place the punched hole at the edge of the anvil at the radius at the left hand end. Take an English hammer with a ball-peen. Bring the ball-peen down on the metal, at a distance of the thickness of the metal away from the anvil. Hit it hard, and guide the hammer so that it hits immediately below the edge, and does not make the metal go in a straight line down the side of the anvil. It must be a curve. That is the beginning of the ring.

Bending metal towards centre punch hole, helping to locate it. The bend also serves to show where the bar should be placed in the fire.

Starting the bend for the ring. The hammer is the thickness of the metal away from the edge of the anvil, avoiding thinning the metal.

Turn the hammer so that it hits the metal against the side of the anvil, and does not make the metal go down the side of the anvil in a straight line. This must be the first part of the ring, and is quite sharply curved.

Now place the next part of the ring in the fire, with the completed part towards the edge where the temperature is lower. When there is enough heat place the already-curved metal over the beak, where the beak is about 40 diameter. Knock the next part of the ring around the beak, hitting the cold end of the taper to use the leverage, until the cool part of the metal is reached.

Keep the ring at the same part of the beak. Remember that its diameter reduces. When the ring has reached past a right angle, place it under the beak, with the hot end upwards, so that the blows will be directed downwards (it is much easier to hit downwards). Continue until the ring is completed, and overlaps the stem until there is an angle of 60 degrees (that is, 8 o’clock).

The next part of the ring in the fire, with the curved portion of the ring out of the side of the fire, keeping cool.

Continuing the ring over the beak, where the diameter is about 40. The metal should only be moved when it is hot, as it will kink if it is cold; reheat if necessary.

The finish of the ring, with tail at 60 degrees.

Taking a pair of flat-bit tongs preferably with long handles and jaws, place them near a vice. Heat the tail material, place the ring in the vice, and pull the tail around the stem, making sure that the angle remains at 60 degrees. Finish by pressing the very end of the tail against the stem.

This ends the making of the rat’s tail handle, which can be used for any number of implements, such as a poker, a shovel or a brush.

Flat bit tongs, preferably with long jaws.

Wrapping the tail with the tongs, keeping the angle at 60 degrees. Care must be taken to see that the angle remains constant, as this affects the shape and appearance of the final tail.

Examples of rat tails; in this case, a companion set made with rat tail handles.

Useful tools for bending

Anvil fork.

Anvil fork

The anvil fork is such a simple tool but so useful. Bends can be made accurately, and incorrect bends can be remade easily with the fork. A series of forks with different width prongs are an asset. There will be many references to the use of forks later.

Scroll wrench, used with fork to bend exactly where required.

Scroll wrench

To enhance the use and precision of forks, a scroll wrench can be employed. This will...

| Erscheint lt. Verlag | 21.9.2015 |

|---|---|

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Kunst / Musik / Theater ► Allgemeines / Lexika |

| Kunst / Musik / Theater ► Malerei / Plastik | |

| Sachbuch/Ratgeber ► Freizeit / Hobby ► Heimwerken / Do it yourself | |

| Sachbuch/Ratgeber ► Freizeit / Hobby ► Kreatives Gestalten | |

| Schlagworte | decorative metalwork • ironwork • sculpture |

| ISBN-10 | 1-78500-034-9 / 1785000349 |

| ISBN-13 | 978-1-78500-034-8 / 9781785000348 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

DRM: Digitales Wasserzeichen

Dieses eBook enthält ein digitales Wasserzeichen und ist damit für Sie personalisiert. Bei einer missbräuchlichen Weitergabe des eBooks an Dritte ist eine Rückverfolgung an die Quelle möglich.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich